Conveying Equipment

The conveyor is a machine that frictionally drives the material in a continuous manner. It can be used to form a material conveying process on a certain conveying line from the initial feeding point to the final discharging point. It can carry out the transportation of broken materials as well as the transportation of individual items. In addition to pure material handling, it can also be combined with the requirements of the process in the production process of various industrial enterprises to form a rhythmic flow line. Therefore, the conveying equipment is widely used in various modern industrial enterprises.

Application Industry of Conveying Equipment

Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieves, kaolin, silica gel, activated carbon, etc.

Pesticide ore: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, sawdust powder, glass fiber, silica, talcum powder, etc.

Food industry: flour, starch, cereals, milk powder, food additives, etc.

Classification of Conveying Equipment

Conveying equipment refers to the material handling machinery that continuously transports materials on a certain line, also known as the assembly line. The conveying line can be transported horizontally, obliquely and vertically, or it can form a space conveying line, which is generally fixed. The conveyor has a large conveying capacity and a long transportation distance, and can also complete several process operations simultaneously in the conveying process, so the application is very extensive.

Belt conveyor

The belt conveyor consists of a driving device, a tensioning device, a conveyor belt, a middle frame and a roller to form a conveyor belt.

As traction and load-bearing member, the bulk material or the finished product is continuously conveyed.

Auger conveyor

Auger conveyor is commonly known as an auger, suitable for horizontal conveying of granular or powdery materials, inclined to convey, vertical transport and other forms. The transport distance varies according to the deformity, generally from 2 meters to 70 meters.

Bucket elevator

The bucket elevator utilizes a series of hoppers that are uniformly fixed to the endless traction member, vertical. A continuous conveying machine that lifts materials. The bucket elevator has the advantages of large conveying capacity, high lifting height, stable and reliable operation, and long service life.

Roller conveyor

Roller conveyors can transport parts with a flat bottom at a horizontal or small angle of inclination products, such as plates, rods, tubes, profiles, trays, box containers and various workpieces. For non-flat bottom items and flexible items, delivery can be achieved by means of a tray. It has the characteristics of simple structure, reliable operation, convenient maintenance, economy, energy-saving, etc. The most outstanding thing is that he can be well connected and matched with the production process, and has functional diversity.

Vacuum conveyor

Vacuum feeder is a dust-free and closed pipeline conveying equipment that transports particles and powder materials by means of vacuum suction. The pressure difference between vacuum and environmental space is used to form gas flow in the pipeline and drive powder. The material movement to complete powder delivery.

Development Trend of Conveying Equipment

In the future, the conveyor will develop towards large-scale development, expanding the scope of use, automatic sorting of materials, reducing energy consumption, and reducing pollution.

Continue to develop into a large-scale.

Expand the scope of use of the conveyor. Develop conveyors that can operate in environments with high temperatures, low temperatures, corrosive, radioactive, and flammable materials, as well as materials that can transport hot, explosive, agglomerated, and viscous materials.

Make the structure of the conveyor meet the requirements of the single handling of the automatic control of the material handling system.

Reducing energy consumption to save energy has become an important aspect of scientific research in the field of transportation technology.

Reduce the dust, noise and exhaust gas generated by various conveyors during operation.

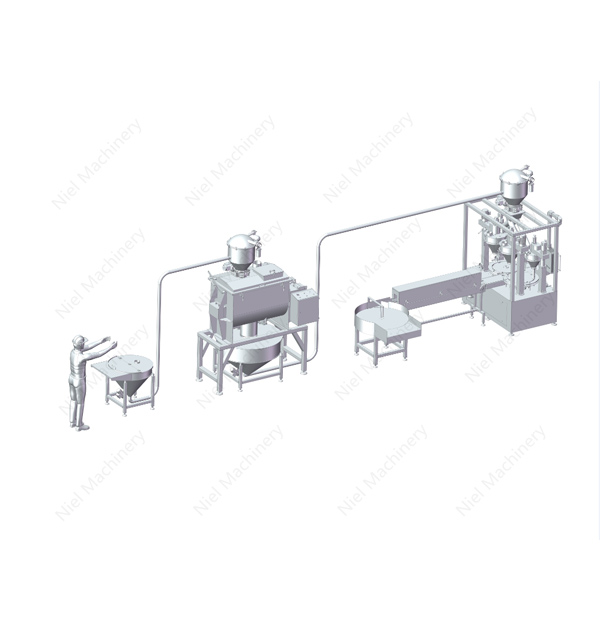

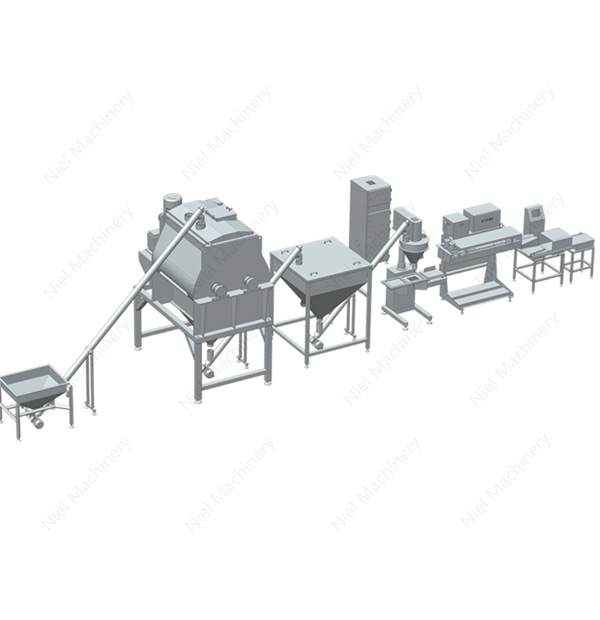

About Neil Machinery

The conveying equipment is one of the main parts of Neil mechanical products. Neil Machinery provides a roller conveyor, belt conveyor, ribbon conveyor, screw feeder, vacuum feeder, chain conveyor, sterilization conveyor, etc. Equipment, and can be designed and manufactured according to the needs of customers. These conveying equipment can form a complete powder production line with other products of Neil Machinery. You can leave a message or consult us according to specific needs.

We produce powder conveying equipment,material conveying equipment,powder conveyorand bulk powder handling equipment,RFQ today.

Send product request

Other supplier products

| Cabinet Cyclone Dust Collector | Description of the powder dust collector The wind motor drives the machine to run. During the process of dust collecting, the dust will be adsorbed... | |

| Powder Mixer Machine | Powder mixer machineis a mechanical device that uniformly mixes two or more materials by mechanical force, gravity, and the like. In the process of... | |

| Powder Filling Packing Machine | The packing machine refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes ... | |

| Powder Mixing And Bag Filling Packing Line | This powder production line is relatively simple in design and is a typical small and medium-sized powder packaging production line. It is suitable... | |

| Single Shaft Paddle Mixer Machine | The structure of the single shaft paddle mixermachine is firm and stable. The mixing paddle and material contact is made of stainless steel. Single... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |