Longer Working Life Hybrid Drill Bits Improve Drilling Effeciency

Overview of Hybrid Drill Bit

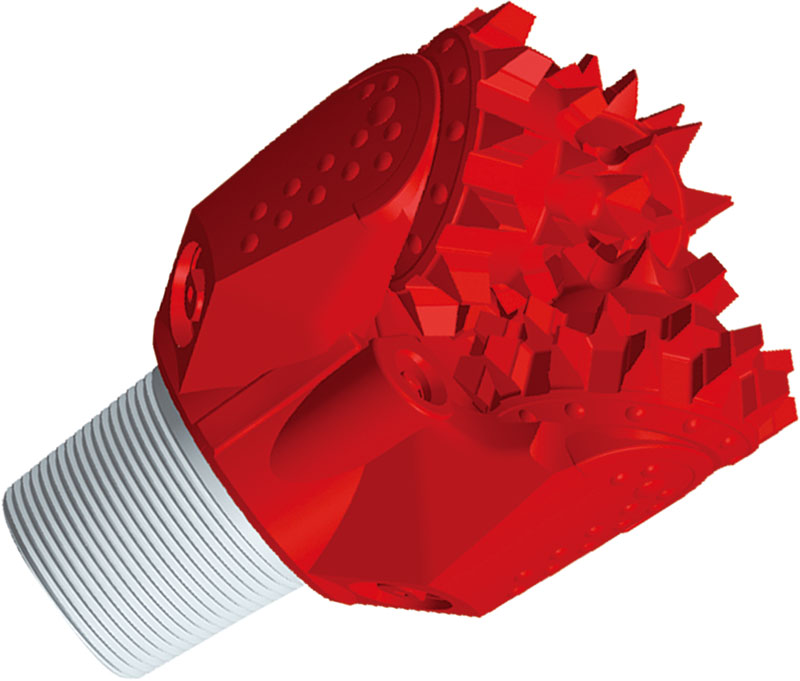

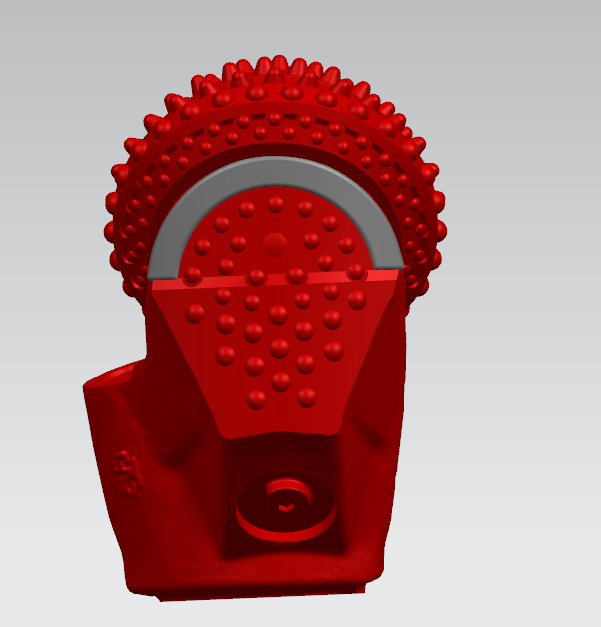

Hybrid drills bits are compounded by the PDC fixed cutting and the roller free cutting structure. The teeth on the cone crush the rock by impact crushing, forming broken pits at the bottom of the well, and making the bottom of the well uneven. It can weaken the strength of the bottom rock. The auxiliary function of the cone facilitates the PDC tooth to enter the formation, which is more beneficial to the PDC tooth scraping and cutting rock.

Developed a personalized composite drill bit series for complex hard-to-drill formations, which has strong formation adaptability in difficult-drilling formations such as hard formation abrasive formations, tight mud shale, and heterogeneous formations such as conglomerate formations. High rock breaking efficiency and fast drilling speed.

Hybrid drills bits produced by GREAT combine PDC and cone drill technology for smoother drilling, better torque management, and precise maneuverability.

The great brand of hybrid drills is a superior directional drill for motor and rotary applications, offering higher cumulative speed capability, damped torque response and precise steering capability on a variety of bottom hole assemblies.

The Advantage of Hybrid Drill Bit

PDC is matched with cone optimization, and the drill bit has strong adaptability and high rock-breaking efficiency in hard-drilling strata.

The hybrid bit utilizes the cutting advantages of PDCs soft formations and the rock breaking strength and stability of roller cones in hard or intercalated formations, with the potential to maintain a higher total rate of penetration (ROP) than an older cone or PDC single bit over a larger range of footage.

The balance analysis and optimization of the composite cutting structure balance the working stability of the drill bit with the adaptability of the formation and improves the service life.

Computational fluid dynamics (CFD) optimization analysis of bit watercourse and nozzle to improve flow field distribution and cleaning cooling effect.

Cangzhou Great Drill Bits Co.,Ltd.is a drill bit factory,we will give you the best service.

Send product request

Other supplier products

| Three Blade Wings Drag Rock Drill Bit For soft formations | Overview of Drag Bit Drag bit are manufactured from forged high-quality alloy steel and hard alloy, plus state of art welding technology and multip... | |

| The Application Field and the Drilling Technology of the Roller Cone Bit | The single roller cone bits rock by crushing and shearing. The cone is rolling at the bottom of the well, so the requirement for the torque is smal... | |

| Three Cone Drill Bit For Soft Formation for water well drilling | Overview of Steel Tooth Bit This superior method provides a stronger, more impact-resistant tooth than milling because the metal particle structur... | |

| Fixed cutter PDC Hole Opener reamer with hard facing for HDD drilling | Overview of PDC Hole Opener PDC Hole opener is designed for the enlargement of pilot holes and large hole applications. They are also used for roa... | |

| Roller Bit | GREAT has customized manufacture several types of roller bit. Our roller cone drill bit includes the 90 ° U-shaped Roller Bit series and the 12... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |