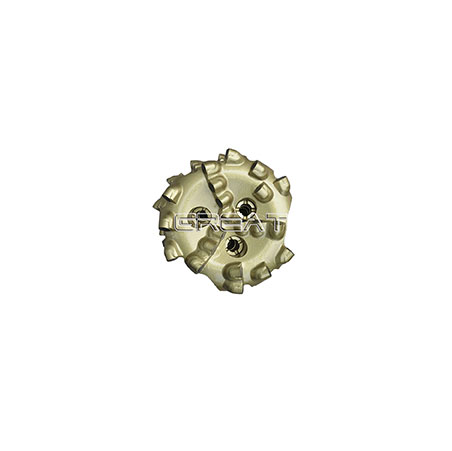

Matrix Body PDC Bit

Great bits design and manufacture a wide variety of Matrix body PDC (polycrystalline diamond cutter) bits. Our PDC bits are offered in a variety of sizes, blade count and cutter sizes.

The Matrix body PDC bitis sintered with tungsten carbide powder. Gauge protection with natural diamond.Tungsten carbide matrix can resist erosion, wear resistance, high strength and good effect of diameter control.

The Junk Slot Area of the bit water hole can be designed according to the hydraulic parameters required by the drilling process. The shape of the Matrix body PDC bit can be designed according to the formation characteristics to achieve the best use effect.

PDC bits are designed for high speed drilling in shale, limestone, and sandstone formations. Unlike roller cone bits , these PDC bits are a one piece matrix bodies with no moving parts. The fixed-cutters shave away the rock, making it possible to operate with higher rotation speeds more efficiently in consolidated formations.

Main Advantages of Matrix Body PDC Bit:

Working on the cutting (shearing) principle, the energy consumption of rock breaking is low.

PDC composite sheet has super hardness, wear resistance and self sharpness.

PDC bit is a fixed tooth bit, no moving parts, high reliability

GREAT Matrix Body PDC Bit Advantages:

Force balanced, resist impact to the blade during high-speed drilling, to make bit work stable.

Plus wear knot section, reduce collision in the high-speed rotational vibration.

Patented matrix formulation, extended bit life.

Optimal hydraulic design, easy to move out the drill cuttings and cooling.

Equipped with back reaming Cutters.

The cutter is high performance to increase the ability of anti-impact and anti-abrasive

We are here to provide you with a unique and custom solution for your specific drilling needs; from design and manufacturing to service in the field. We have what you need.

We are one of the best drill bit manufacturers in china,we produce Great Drill Bits,welcome to buy it.

Send product request

Other supplier products

| Bi-center bit for Mining Machinery and abrasive formation | Overview of Bi-center Bit This type of bicenter bitmainly used for medium to medium-hard compressive and abrasive formation, it has medium and h... | |

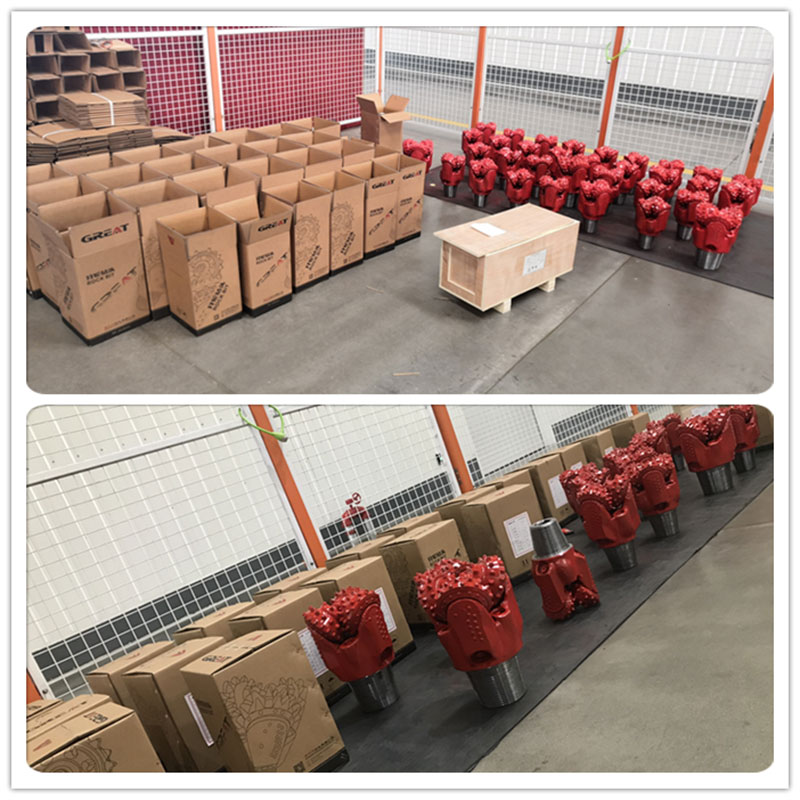

| Shipping Info | Shipping Info Our PDC bit and bi-center bit, PDC reamer with iron packaging, equipped with high-quality shackle device, convenient for the extract... | |

| Matrix Body PDC Bit | Matrix Body PDC Bit Cangzhou Great Drill Bits Co.,Ltd., as one of the professional drill bit manufacturers in China, we design and manufacture a w... | |

| Matrix Body PDC Bit For Oil Well Drilling Hard Rock | Overview of Matrix Body PDC Bit GM1605T Matrix body PDC bit GM 1605T is made by Tungsten carbide powder, this type of matrix body bit is very high... | |

| Reverse circulation PDC bit for geological exploration samples | Overview RC PDC Bit RC PDC bit from GREAT are manufactured from AISI 4145H heat-treated steel, rc bitare widely used in geological exploration sam... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |