Automatic Loading and Unloading Nesting CNC Router Machine

Description of Nesting CNC Router

- The purpose of the nesting router machine is to obtain higher productivity from the CNC with fewer hands. One person can operate the machine because all materials are automatically processed, which really makes the operator’s job much simpler. Tool changer, unloading equipment. It can automatically complete the whole process of preparing, feeding, fixing, cutting, engraving, and unloading MDF wood.

- Through intelligent, user-friendly, and highly automated operation, the machine can make it easier for operators to process all information, and anyone can learn to operate within a few hours, thus saving labor costs.

- A highly automated discharge solution with automatic loading and unloading systems. The cycle of loading, nesting, drilling, and unloading is automatically executed when the work is completed, thereby maximizing productivity and zero downtime.

- A truly multifunctional nested engraving machine, vertical drilling, and engraving can be done at the same time. Very suitable for furniture, office furniture, cabinet production.

- Automatic feeding, cutting optimization, vertical hole drilling, automatic cutting coherent, continuous process, maximize efficiency output.

- Save time and effort, save materials, automatically optimize layout, and improve material utilization. High quantity, automatic design, automatic typesetting, no manual intervention, minimize the error rate and ensure the quality of the order.

- Position sensors and positioning cylinders meet the requirements of high-precision orientation and highly automated production lines.

- Highly automated discharge solution with automatic loading and unloading system. The entire work cycle of loading, nesting, drilling, and unloading is performed automatically, thereby achieving the highest productivity and zero downtime.

The advantage of CNC router with loading and unloading table

- High precision and reliability over time

- Maximum productivity, minimum footprint

- High processing flexibility

- Machine customization depending on different production requirements

- Full automatic and save labor cost

Features

- Multi-Tool CNC Router: According to different processing requirements, the required spindle starts to work, and the other spindles are in the standby state. This not only saves the time of manual tool change but also improves production efficiency.

- Humanized machine control interface design: Workers can operate the machine proficiently with simple training. The high efficiency of the machine can help you achieve a leap in productivity.

- Special boring head: There is a special drilling package next to the spindle, which can quickly drill and mill, improve the efficiency of furniture splicing and reduce labor costs.

- Automatic unloading platform: conveyor belt unloading system, saves manual picking time, realizes complete automation, and effectively reduces labor costs.

- Automatic feeding, optimized opening, vertical hole punching, and automatic unloading can be done in one go, without interruption in the process, to maximize efficiency and output.

- Strong Body: Precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

- Machine size is customizable depends on the customer’s panel size. We can build such as 1300*2500mm,1500*3000mm,2000*3000mm,2000*4000mm, and so on.

Machines pictures:

Automatic Tool Calibration:Effectively save the time of manual toolset, and the toolset is convenient and quick

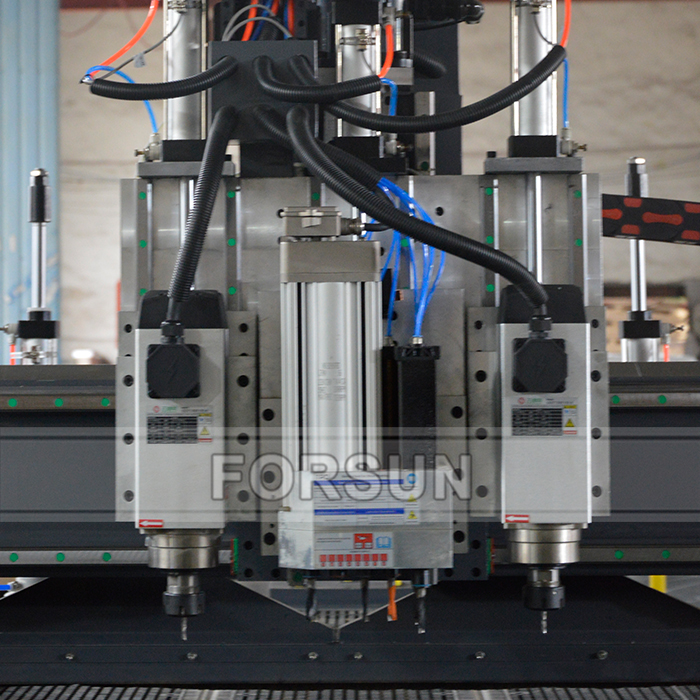

Boring Head and Spindle:The air-cooled spindle has a high speed and strong cutting force, which greatly reduces the machine failure rate; the boring head greatly improves work efficiency

Feeding Roller:Adding a roller at the back of the table to load the material is more labor-saving, and it is easy to transfer the plate and effectively avoid the plate from being scratched during the feeding, which greatly improves the work efficiency.

Material Grasp Cylinder:After the work of the whole machine is completed, the material is automatically pushed, which saves time and effort and improves production efficiency.

Servo Motor and Reducer:High-precision servo motor, stable operation, high-efficiency, and long-lasting production. High precision reducer: The reducer has the advantages of small size, lightweight, strong load capacity, long service life, high reliability, low noise, large output torque, and high efficiency.

Vacuum Table:The vacuum adsorption table has large holes, strong adsorption force, and humanized auxiliary feeding device, which is convenient and saves manpower.

Auto Unloading Table:Combining the conveyor unloading table with the automatic indexing table and the material loader can provide a fully automatic material handling solution for your factory. Very popular in nested production.

Auto Loading Table:It is designed to automatically pick up the plates from the indexing material lifter and place them on the machine tool to be cut. It is very suitable for high-production environments or environments where OH&S problems are caused by manual handling of heavy plates.

Suitable Materials

- Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard

- Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE

- Stone: Granite, Marble, Slate, Basalt, Pebbles, Natural Stone, Ceramic, Porcelain

- Soft Metal: Aluminum, Brass, Copper, Mild Steel

- Composite: Aluminium Composite, Copper Composite, Titanium Composite, Zinc Composite.

Applications of auto wood nesting CNC router

1) Furniture industry: cabinet doors, wooden doors, solid wood, plates, antique furniture, doors, windows, desks, and chairs.

2) Decoration industry: screen, wave board, large wall decoration, advertising board, and sign production.

3) Handicraft industry: Carving on artificial stone, wood, bamboo, marble, organic board, two-color board, etc. to achieve exquisite patterns and text effects.

4) Processing materials: Engraving, milling, and cutting of acrylic, PVC, density board, artificial stone, organic glass, plastic and copper, aluminum, and other soft metal plates.

Projects by Nesting CNC Router

About FORSUN:

Jinan FORSUN CNC Machinery Co., Ltd., one of the professional Wood CNC Router manufacturers and suppliers in China, has been focusing on providing high-quality CNC Router Machines and solutions for worldwide customers for 20 years. Main computerized CNC machine types: Wood CNC Router, 3d CNC carving machine, Wood CNC machine, ATC CNC router, Basic beginner CNC router, Mini desktop CNC router, Multi-Tool CNC machine, Rotary axis CNC engraver, 4/5 Axis CNC milling machine, CNC marble stone engraving machine, CNC plasma cutter, CNC foam cutting machine, CO2 laser cutting machine, fiber laser cutter, etc.

Forsun CNC Router helps you stay productive. We have the right CNC Router Machine tools for your application and we’re supporting you every step of the way.

Send product request

Other supplier products

| New ATC CNC Router with Aggregate and the 4th Rotary Axis | The Main Introduction of New ATC CNC Router with Aggregate Forsun ATC CNC Router is a true CNC Router machine grade tool with everything you could ... | |

| New ATC CNC Router 5×10ft with Automatic Pusher Device | ATC CNC Router 5×10ft with Automatic Pusher Device: 5×10ft Automatic Tool Change CNC Router is an extremely compact and high-performanc... | |

| 2021 Hot Selling CNC Wood Router with Rotary Axis | Description 4×8 CNC Wood Router with Rotary Axis CNC Router is the perfect tool for a woodworking shop looking to expand their capabilities. ... | |

| Automatic Edge Banding Machine For MDF Woodworking Machinery | This edge banding machine of FORSUN CNC can bring you perfect results of high-quality workpieces. This economical machine has automatic gluing, tri... | |

| ATC CNC Router Machine with HSD Aggregate Head & 3 Axis Dust-Proof | ATC Wood CNC Router Machine with 4 sides aggregate This automatic tool change CNC router machine is equipped with HSD brand aggregates from Italy f... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |