CNC Boring Mill

Sealion Machine Tool is a machine tools companythat specialized in the lathe in both vertical and horizontal, floor type horizontal boring machine, CNC machining center, and rotary table. The production facility is located in Anhui, Wuhu. Based on the 30,000 square meter plant, we manage to satisfy all demands of our customers.

Cnc milling machine suppliersand boring mill manufacturersboth floor type and horizontal boring & milling machines. For the floor type boring machine, SEALION boring mill machinemanufacturers offer you spindle size from 130mm up to 250mm, with or without square ram. It can work with a rotary table, boring millattachment, facing head. For the horizontal boring and milling machine, SEALION boring mill manufacturer offers 110mm or 130mm spindle with facing head and rotary table. CNC boring mill machines and automatic milling machines are widely used in big size job machining, such as earthmoving, motors, airplanes, nuclear power, wind power, etc. SEALION provides full lists of attchments, boring machine tools or your various needs. It has the functions of drilling, reaming, boring, milling and turning threads, and so on.

What is a CNC Milling Machine and How does it Work?

CNC milling machines are extremely useful machines for commercial and industrial production. CNC milling machines use rotating cylindrical tools to move along multiple axes and create grooves, holes and details in the material to transform it into a vehicle or machine part. Most machines operate on three to five axes, thereby creating greater precision and detail. Modern CNC milling machines are assembled into horizontal and vertical machining centers.

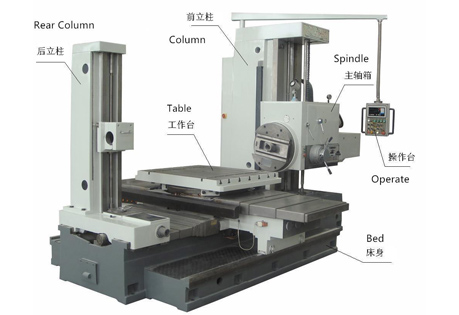

Difference Between Horizontal And Vertical Boring Machine

The difference between a horizontal boring and milling machine and a vertical boring machine is that the workpiece of the horizontal milling cutter is stationary and the tool rotates. When the workpiece rotates, the vertical boring and milling cutter will have a fixed tool. Horizontal boring and milling machines have more versatility, because the machine may have unlimited part size functions and may have special options.

What can CNC Boring Mill Do?

Important application of CNC boring mill include finishing of internal surfaces and drilling of heat-sensitive or non-ductile materials. One of the main purposes of CNC boring mill is to make the inner surface of the cut hole rough or smooth. Here, the tools used can help texture the inner surface of the hole in a specific way. Sometimes this is done when refurbishing a product instead of making a new product. As a physical shearing process, cnc boring mills can ream holes in materials that are not suitable for thermal or electrical based drilling methods (such as laser cutting or electrical discharge machining). Manual boring mill are most suitable for reaming. Although CNC boring mills may have the accuracy required for drilling or partial blind holes, this is still not their preferred application.

Benefits of CNC Boring Mill

Tool deflection or machining process deviation occurs when the tool encounters more resistance than can be easily compensated for. For example, when the main spindle is too far from the anchor rod, if it is placed under the anchor rod, it will be unusually excessive for a certain angle of drilling. With a CNC boring mill, the spindle can be taken out of the spindle box, which means that the spindle can be kept short to prevent tool deflection, which leads to more consistent drilling.

CNC boring mills may not be exciting, but they are rugged and reliable tools, especially when they are well maintained. With proper maintenance, they can last for decades, which makes second-hand CNC boring mills a particularly ideal investment to maintain their value.

As a professional cnc milling company, we supply types of milling machineand for sale cnc milling machine, if you want to know cnc milling machine price, please contact us.

Send product request

Other supplier products

| 2-Axis CNC Single Column Vertical Lathe | 2 axis cnc lathe machineX&Z is using a brand linear guideway. The main transmission of 2 axis latheis driven by frequency or a servo motor, sim... | |

| Vertical Lathe | Sealion Machine Tool supplies a wide range of vertical lathe machine -- single column vertical lathe, 2-axis CNC single column vertical lathe, doub... | |

| CNC Horizontal Boring Mill | SEALION supplies Horizontal Boring Mill both 110mm and 130mm spindle, with or without the back column. Great cost performance is the main advantage... | |

| CNC Machining Center | From the vertical type and horizontal type to gantry type, Sealion Machine Tool offers you a wide range of CNC Machining Center. With our hard-work... | |

| Gantry Machining Center | SEALION supplies gantry type vertical machining center both tables moving type or gantry moving type. Gantry cnc machine center is widely used in t... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |