Potato Starch Making Machine

Features of Potato Starch Making Machine

Potato Starch Making Machine

Potato Starch Process Description and Flowchart:

Goodway has been continuously developing potato starch making machine since 1991 to maximize product quality. From potato root hopper until the packaging stage, we can supply machines together with production process know-how.

The production process of potato starch comprises the steps such as delivery and unloading potato, washing, crushing slurry and residues separation, desanding & desilting, starch concentrating and refining, de-watering, starch drying, and packaging. We provide below a brief description of the main steps of the potato starch production process.

Note: Goodway updates the potato starch machineand potato starch processingproduction line technology and machinery based on the latest experience. This starch manufacturing machinery also can be used as cassava starch making machine.

Potato Starch Production Process

Cleaning and Washing Potato Roots

Wash the fresh potato roots in clean water to remove the surface mud and sand. It's the first step of potato starch process and very important for the quality of final potato starch.

Crushing Washed Potato Roots into Slurry

Crushing the washed potato roots into the slurry and separate to remove the coarse potato residues to obtain uniformly smooth potato slurry. The crushing drum and all food contact areas should be made from stainless steel.

Potato Slurry and Residues Separation

The commonly physical operation to separate fine potato residues from potato slurry. Oversize particles of potato residues cannot pass through the lattice structure of the filter, while fluid and small particles of potato slurry can pass through to become filtrate.

Raw Starch Milk Desanding and Desilting

Solid control equipment that separates tiny sand and mud from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Starch Refining and Concentrating

When raw starch milk enters the hydrocyclone, the pure starch milk of high density getting larger centrifugal force leaves from the underflow outlet, and the protein and other soluble impurities of low density getting smaller centrifugal force leave from the overflow outlet. Finally, achieve the purpose of various components of separation, and improve the quality of final starch with higher whiteness and purity.

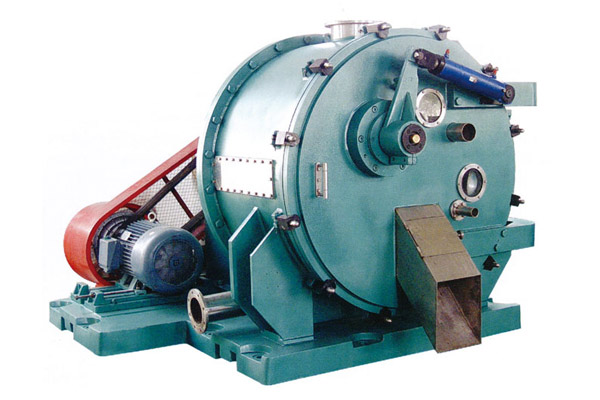

Pure Starch Milk De-watering

De-watering the pure starch milk to the low water content of 35-40% by the principle of vacuum suction filtration. Ensure sufficient water has been removed, otherwise, the starch will form into lumps during drying.

Drying Wet Starch into Dried Starch

Effectively dry the wet starch into dried starch with low moisture content by the principle of heat transfer exchange. The drying process is more reliable and of higher quality.

Nanyang Goodway Machinery & Equipment Co., Ltd. is a leading rotary vacuum filter manufacturers, focus on providing the system solutions in the fields of Cassava Starch, Potato Starch, Sweet Potato Starch, Cassava and Yam Flour, Garri/Gari, Fufu Flour, Cassava Chips processing since 1991 in the worldwide.

Send product request

Other supplier products

| Cassava Vibrating Sieve | Features of Cassava vibro sifter sieves Break the pressed cassava cakes into granules and separate the uniform size granules from the lumps to obt... | |

| Cassava Garri Fryer | Cassava Garri FryerVIDEO Features of Cassava Garri Fryer Machine Processing Capacity: 100-300kgs/hour Application Scope: Garri frying or roastin... | |

| Centrifugal Dewatering Machine 2019 | Features of Centrifugal Dewatering Machine Processing Capacity: 1-10Tons/hour Application Scope: Cassava or potato starch dewatering Product Introd... | |

| Garri Fryer(Cassava Garri Fryer) | Features of Garri Fryer(Cassava Garri Fryer) Roasting be done mechanically using an automated garri fryer made of stainless steel material and wi... | |

| Cassava & Potato Processing Line | As a professional and reliable manufacturer and supplier, Goodway focus on designing and providing turnkey solutions of cassava & potato proces... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |