Selection and Function of Pick and Place Nozzle

Generally speaking, the SMT industry knows that the smt machine nozzleis a key component of the SMT machine. It is used to pick up and place SMT components. There are many types of SMT nozzles on the market, including steel, ceramics, plastic steel, plastic, aluminum alloy, and iron. According to the shape, there are round holes, square holes, V-shaped, etc., and there are many kinds according to the different sizes.

Ⅰ. The choice of SMT pick and place nozzles

- pick nozzleshape of the placement machine:

The nozzle shape has square hole, round hole, V groove, etc. Custom-made pick and place machine nozzlegenerally choose flat suction points according to the shape of the material. Some are made as elongated nozzles, and the grooves that extend the material are used for suction. Some are made into a back shape according to the edge of the material, and some are two-sided. Use a flat surface at the end and build a bridge if the middle is uneven. Some materials are sticky and are not easy to discharge, so some grooves should be made in the nozzle wall or made into rubber heads.

For standard materials, the nozzle specifications are basically fixed. For example, 0805 materials correspond to CN065 nozzles, 0603 materials correspond to CN040 nozzles and so on. When some materials are not big or small, and have strange shapes, the nozzle needs to be customized.

Ⅱ. The role of the SMT pick and place nozzles

TheSMT pick and placenozzlesare not only the key part of the placement machine to paste and release the components that are sucked, but also the background when the camera of the optical vision system takes pictures. It mainly uses the suction effect of vacuum to suck the components. Use air blowing to put the components adsorbed on the suction nozzle to the coordinate position of the circuit board.

When the suction nozzle of the pick and place machinesucks components, in order to achieve the ideal situation, it is necessary to ensure that the center of the component, the center of the suction nozzle, and the space center of the obtained image should be coincident, and the adjustment of the optical vision system actually requires compensate the deviation caused by this non-coincidence in actual work.

Different mounting components need different suction nozzles to suck. Almost every pick nozzle will have a reflective background, which is mainly to have a good background when the image is taken, so as to ensure that the target information is accurately highlighted when the image is processed. The SMT nozzles are used as the background when extracting the image. The image contrast of the component is enhanced and more clearly visible.

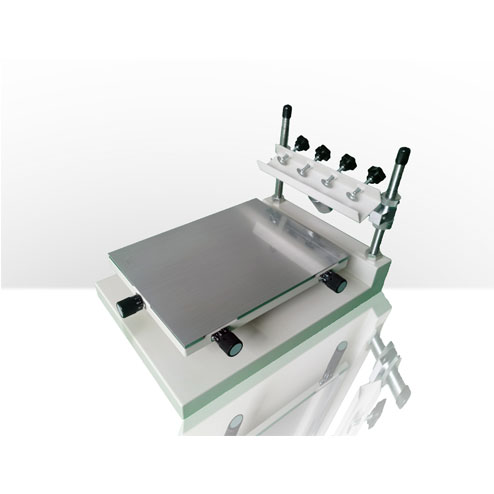

We also have china solder printing machinefor sale, if you have needs, please contact us.

Send product request

Other supplier products

| ACCESSORIES | The entire SMT production line generally requires conventional SMT pick and place parts: nozzles, feeders, etc. For all products in the warranty, o... | |

| High Precise Screen Printing Table TP3040 | High Precise Screen Printing TableTP3040 Please move down to understand the parameters and information. TP3040 high-precision manual printer ... | |

| Electric Feeder | The electric smt feedersis mainly suitable for the Trosntol A1 automatic pick and place machine. This kind of pick and place feederonly needs elect... | |

| SMT Equipment in Automotive | Due to the intelligent development of automobiles, the application range of PCB pick and place machine in the automotive field is becoming more and... | |

| About Full-automatic Solder Printer PM400A | This automatic soldering printeris the latest release of our printer. It features the latest machine vision recognition system, adopting highly pre... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |