H-Beam Welding Line

Hbeam machineconsists of an assembling machine, front welding machine, turn-over device, back welding machine and the transmission conveyors. It is used to assemble the H-beam,180°turn-over and transmit, etc. The annual welding capacity is 8000 tons. The Max welding speed can reach about 2m/min.Regularly, we adopt Lincoln welding machine (DC-1000) and NA-5 control system.

JH-150A h beam weldingline for H-profile steel is a wonderful technical product that integrates mechanical, electric, and pneumatic technologies. The machine, using advanced technology of single-arc double-wire welding, greatly increases the production efficiency.

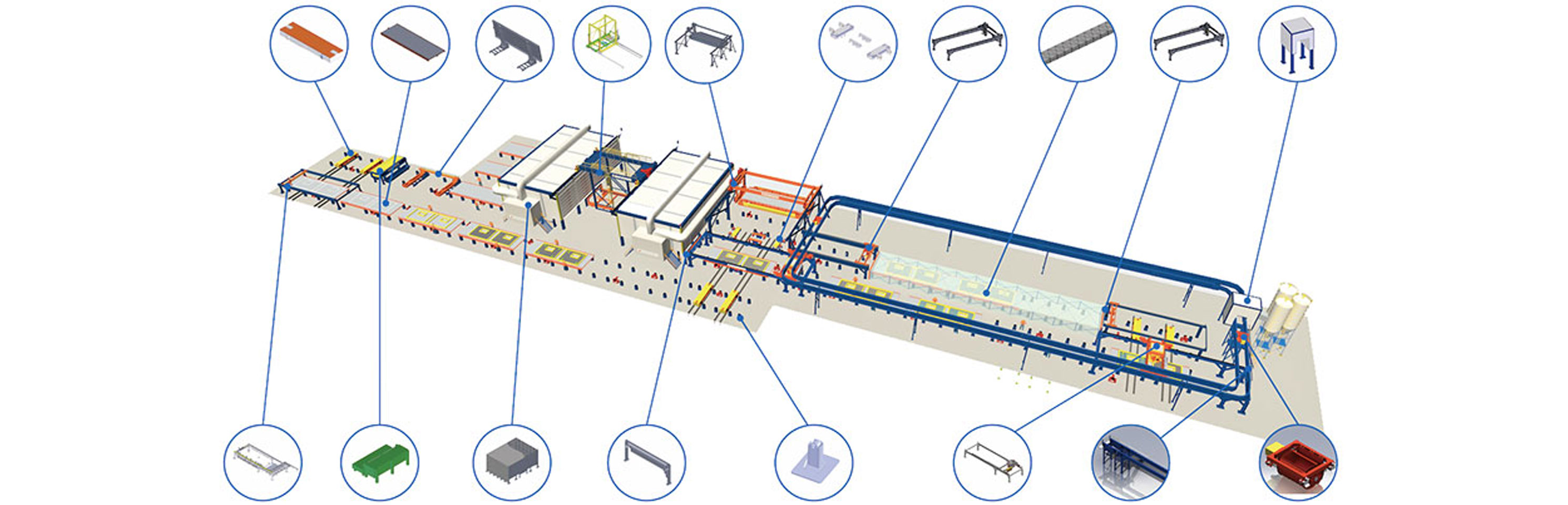

The half line and whole line of H-Beam Welding Line Machineare different. The whole production line includes the turnover device and a second welder and it's related roller conveyor, while the half production line doesn't include the above-mentioned parts.

H-beam welding line, which is developed by Zhejiang JinggongScience and Technology Co., Ltd., achieves the quality production of H-beam. It's the most advanced H-beam equipment domestically. H-beam welding line consists of the assembling machine, main welder, turnover device, and conveyor, etc.

Hbeam welding lineis very well received and widely applied by most steel structural enterprises for its high efficiency, big production scope, easy operation, and small space, etc.

Technical Parameter OfH-Beam Welding Line

|

Item |

Parameters |

||

|

H-beam specs |

(mm) Web width |

300-1200 |

300-1500 |

|

(mm)Web thickness |

3-10 |

3-12 |

|

|

(mm)Flange width |

150-500 |

||

|

(mm)Flange thickness |

5-16 |

5-20 |

|

|

(mm) H-beam length |

4000-15000 |

||

|

(kg) H-beam weight |

4000 |

||

|

Inclination of H-beam |

≤15° |

||

|

Total Power |

64KW+90KVA×4 |

||

Size Of Raw Materials Required For H-Beam Welding Line

Web height: 250-1500mm

Web thickness: 3-12mm

Flange width: 150-500mm

Flange thickness: 5-25mm

Length suitable workpiece: 2000~15000mm

Components of H-Beam Welding Line

Assembly Machine

The assembly machine is the first stage before entering the main welder. Before entering the main welder, the web plate and flange plate are to be assembled. By stop welding the two heads of the workpiece, H-beam assembling can be completed to go on the next stage.

Main Welding Machine

The main welding machine is the main equipment for this production line. After the assembled three plates are fed to the main welder through the conveyor, the welding process is started, and through positioning, clamping, and adjustment, until the whole process is completed.

Turnover Device

The turnover device is the assisting equipment of H-beam welding, one side welded H-beam will be transported to turn over device through the conveyor, and to turn over about 180 degrees, and to go on through conveyor to the main welder for welding the other side.

Compared with the traditional welding line, the H-beam welding line has the following seven advantages:

Jinggongis a professional roll forming machine company, we provide continuous sandwich panel line, china roll forming machine, flame cutting machine for sale, etc.

Send product request

Other supplier products

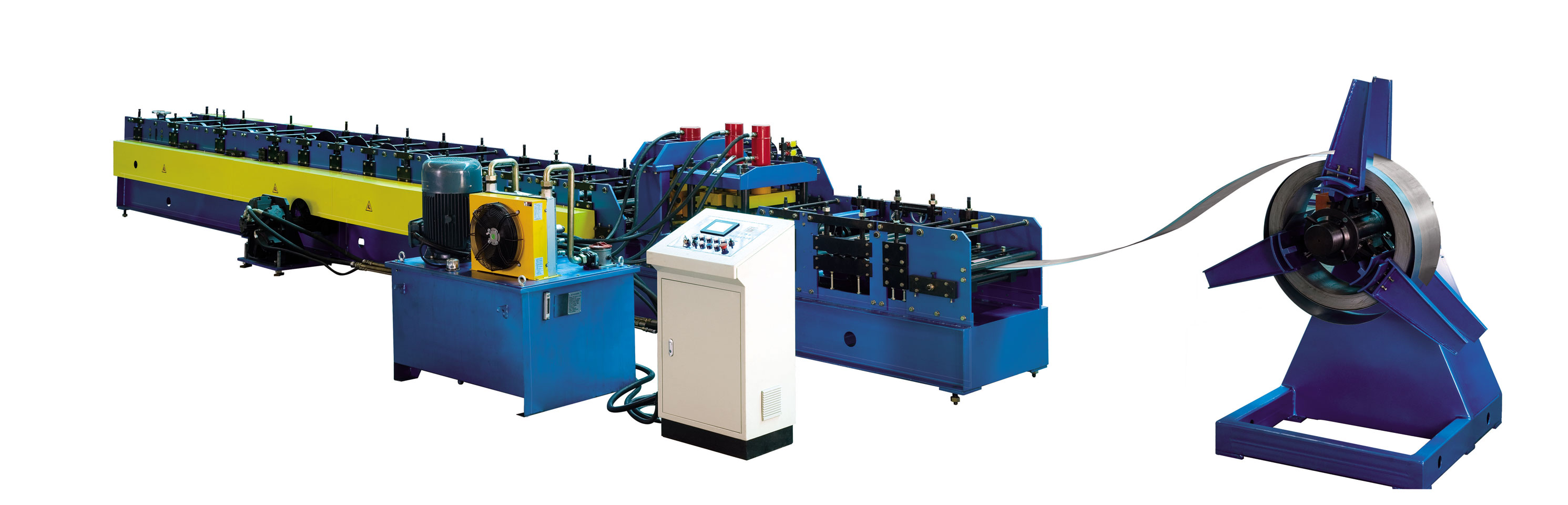

| C/Z Purlin Roll Forming Machine | The C/Z purlin roll forming machine can form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C... | |

| Precast Concrete Panel Production Line | As the main component in precast concrete components, the assembly part, connection, combination of cast-in-place reinforced Concrete structure, PC... | |

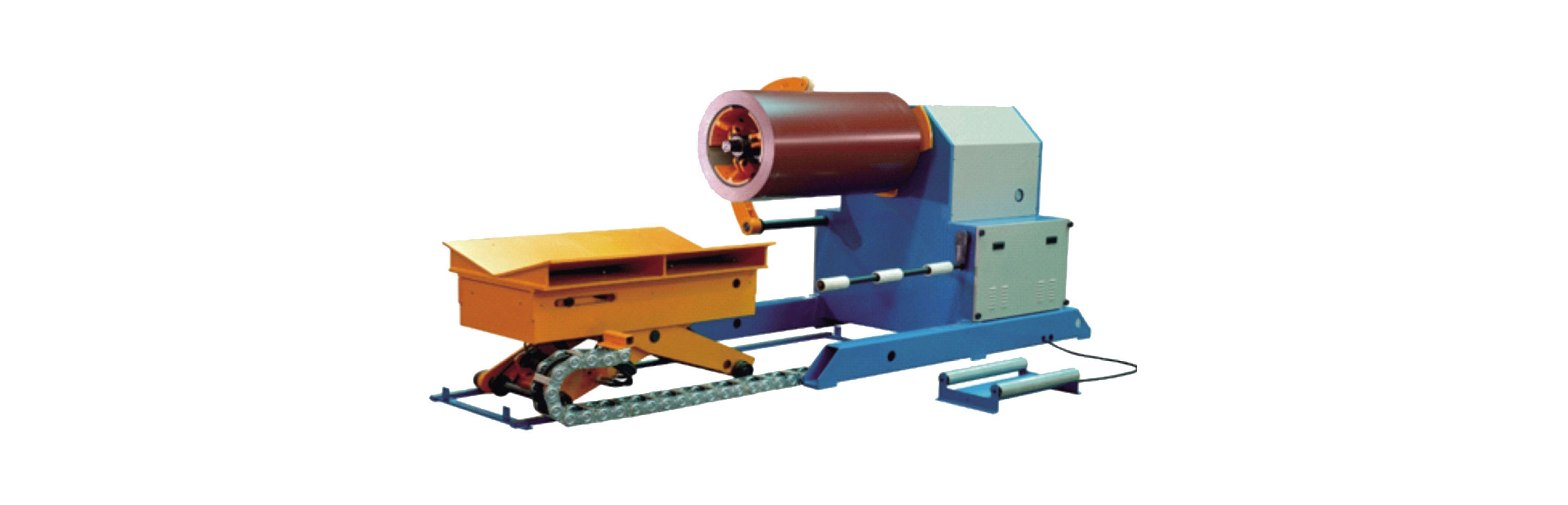

| Uncoiler | Our uncoiler machine is suitable for the uncoiling and conveying of thin metal sheets. It is the auxiliary equipment forroll forming machines. The ... | |

| PU/PIR Continuous Sandwich Panel Production Line | Continuous PU Sandwich Production Line, also calledpolyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is... | |

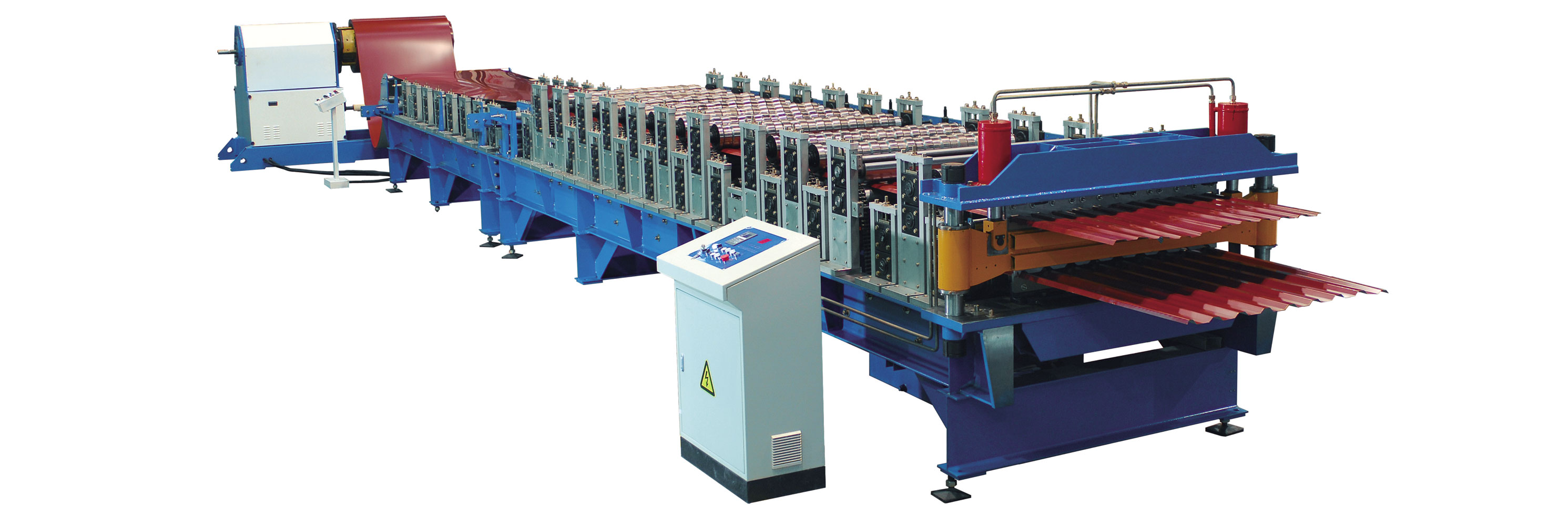

| High Speed Roll Forming Machine | The high speed formingmachine is the new type line which is produced both by our company and Formia company from Finland. The complete machine adop... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |