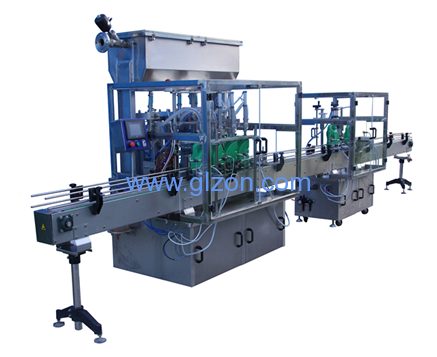

1-5L chemical liquid filling machine

GZM1000-16F intelligent high viscosity filling machine is suitable for packing non-viscosity and high viscosity materials. The whole machine is in-line structure, and the principle of servo motor driven filling and volumetric metering filling is adopted, which realizes the high precision of filling dose. PLC control and touch man-machine interface are adopted, and the whole machine is convenient and intuitive to operate. High-precision electronic scale automatic weighing data transmission system can be selected, and the dose adjustment is faster.

Equipment characteristics

1. all parts in contact with materials are made of 316L stainless steel and sanitary pipes, and all connecting parts are made of quick-connect interfaces.

2. The servo motor controls the diving filling mode in which the belt drives the filling head to run, and with the settable variable-speed filling function, the filling head rises with the rise of the liquid level, synchronizing with the liquid level, which can reduce the generation of foam in the filling of easily foaming materials, prevent the bottle mouth pollution caused by material overflow, and effectively improve the production capacity.

3. The servo motor drives a stable double screw transmission mechanism, which ensures the high precision of the piston movement stroke.

4. According to the 9-year research and development experience and market feedback of high viscosity filling machine, our company developed the filling three-way valve successfully. The three-way valve has the advantages of simple structure, reliable performance, long service life, reliable sealing and no leakage after long-term use.

5. The piston seal with tetrafluoroethylene technology improves its anti-wear performance (service life is more than 24 months) and applicability to materials.

6. The whole machine is made of high-quality SUS304 Taigang stainless steel frame, and the parts in contact with materials are made of high-quality 316L stainless steel, which has good anti-corrosion effect. The machine body is sealed by stainless steel and tempered glass door cover, and an air outlet (the diameter of the connecting pipe is φ 120) is reserved above the filling head, which can be connected with the air induction system of the factory to discharge the waste gas generated in the filling process, so as to ensure that there is no peculiar smell in the production workshop.

7. If the filling machine is short of bottles, it will not fill, and if the bottle is blocked, it will automatically suspend the bottle discharge. At the same time, the rear side is equipped with a coordination photoelectric device.

8. Automatic transmission system of weighing data of electronic scale. There is no need to manually input the weighing value during dose fine-tuning. Just place the filled container on the scale, and click to confirm the number of filling head to complete the dose adjustment. (This function is optional)

III. Main technical parameters

1 Production capacity: ≤3600 bottles/hour

2 Suitable bottle type: round bottle-square flat bottle with diameter φ 40-90mm and bottle height 80-230mm-length 40-90mm, width 40-90mm and height 80-230mm.

3 Filling capacity: 80-1000ml

4 Measurement accuracy: (200ml) 1%; (200ml-1000ml)±0.5%

5 Air source pressure: 0.6 ~ 0.8 MPa

6: ~ 380V, 50Hz

7 Power: 2.5 kW

8 Overall dimensions of main unit: 2435× 1253× 2300mm (length× width× height)

9 Weight of the whole machine: about 1850kg.

1. Highlights: It integrates filling and capping, with compact structure and small occupied space.

2. Highlights: It is suitable for filling production of all kinds of liquid (aqua or high viscosity) materials.

3: It can be directly washed with water, which is simple, convenient and quick.

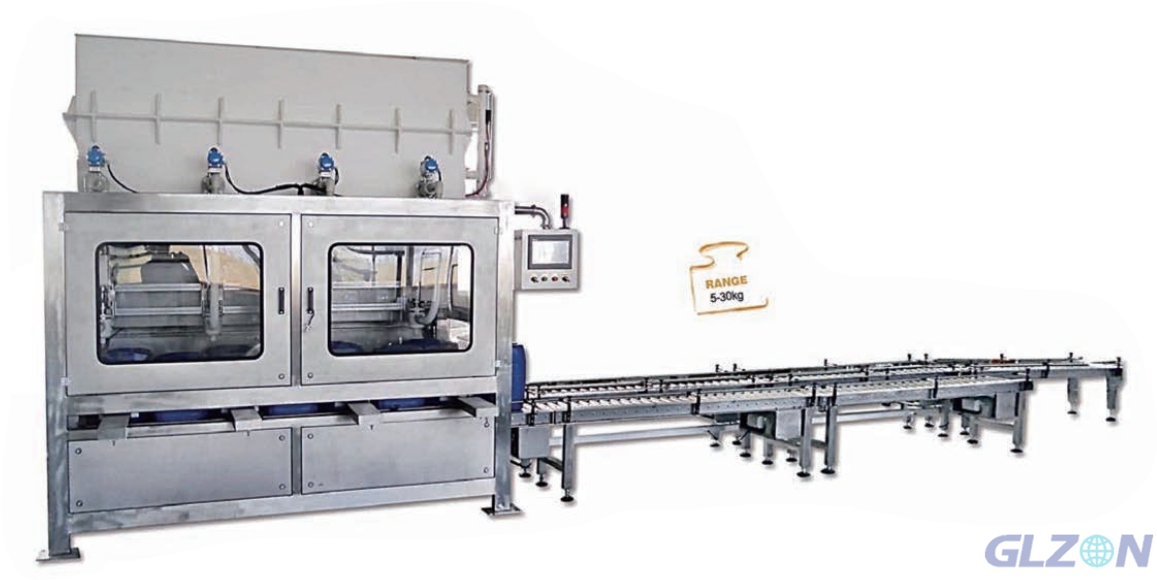

Technical parameters:

1. Production speed: ≤360 barrels per hour (take 5L as an example)

2. Applicable bottle shape: round bottle diameter φ Φ80-140mm, flat bottle 80*80*100mm-140*200*300mm.

3. Measurement accuracy: 0.5% (take 5L as an example)

Product features:

This product is suitable for packaging 1-5L bottled liquid.

Other supplier products

|

|

Bagged popcorn packaging production line equipment |

Bag popcorn packaging production line equipment film width: 420mm Bag length: 50-300mm Bag width: 60-200mm Packing speed: 5-70 packs/minute/set Mea... |

|

|

GZM-1S drop box loader |

This machine is mainly used for packing at medium and low speeds, and adopts side-pushing whole-row technology, with small floor space, reliable pe... |

|

|

GZM-30AF Automatic Strong Acid Filling Machine |

The system is made of PLC programmable controller and touch screen, which is safe and reliable. Automatic barrel feeding, filling and discharging w... |

|

|

Pneumatic self-leveling mortar packaging machine |

Product introduction: Shanghai Guangzhi Instrument & Equipment Specializes in the production of packaging machine for quantitative packaging o... |

|

|

GZM-Q robot stacker |

Main technical parameters Robot stacker is suitable for the production enterprises of lubricating oil, edible oil, coatings, daily chemicals, food,... |

All supplier products

Same products