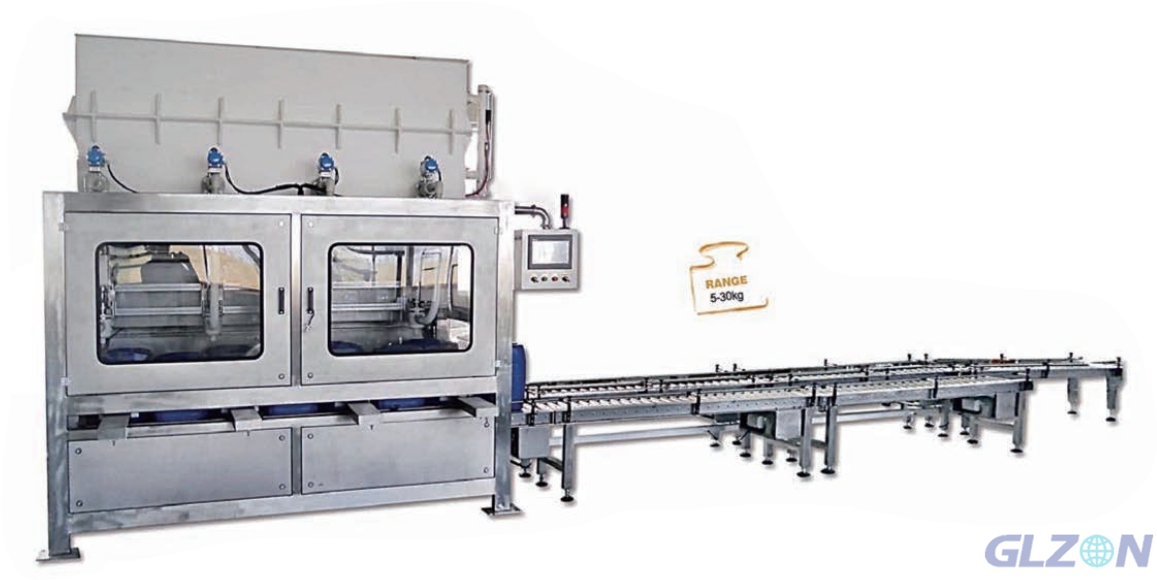

Wide-mouth barrel filling machine

Wide-mouth barrel filling machine for lubricating oil, fertilizer and urea solution

1. Product introduction:

Wide-mouth barrel filling machine is suitable for weighing filling of fluid 10kg-30kg. Complete a series of operations such as automatic counting into bottles, weighing filling, conveying out bottles, etc. It is especially suitable for quantitative filling of aqua and paste, and is an ideal packaging machine for food, medicine, cosmetics, fine chemicals and other industries. This machine adopts programmable logic controller (PLC) and high-speed industrial control configuration software for real-time monitoring and control, which is convenient to use and adjust. The whole machine is made according to GMP standard. Each pipeline is connected in a fast way, which is convenient for disassembly and cleaning. The parts in contact with materials and exposed parts are made of high-quality stainless steel. The whole machine is safe, environment-friendly, safe and beautiful, and can work in different environments.

2. Technical parameters:

1. Overall dimensions: 2200 (length) ×1350mm (width) ×1820mm (height)

2. Number of filling heads: 2 heads.

3. Applicable bottle type: customized according to bottle type.

4. Diameter of barrel mouth: customized.

5. Packing specification: 5-30L

6. Production capacity: 250 barrels per hour (calculated by 20 liters);

7. Measurement error: 0.1%

8. Equipped with power supply: 220V;; 50Hz

9. Main engine power: 3KW

10. equipped with gas source: 0.55Mpa-0.65Mpa clean and stable gas source.

Liquid filling machine, dry powder mortar packaging machine, automatic filling equipment, ton bag packaging machine.

3. Principle features:

1. The weighing instrument of the wide-mouth barrel urea solution filling machine is a special controller for the quantitative packaging scale, with fast reaction speed, high precision and complete functions.

2. The weighing sensor is TOLEDO intrinsic safety sensor, which is sealed by multi-layer medium, and has strong anti-eccentric load capability, and has the characteristics of dustproof, waterproof, explosion-proof, anti-button, and corrosion resistance, and conforms to IP67 sealing standard.

3. The contact materials are 304L stainless steel and PTFE, which are acid-resistant and corrosion-resistant. Special materials can be customized according to the material properties.

4. The material flow rate is controlled by the two-speed ball valve and the bottom valve of the spray gun, which is accurate and reliable. Users can adjust the filling speed through the instrument keyboard.

5. All valves can be closed automatically when the air pressure is insufficient and the goods are cut off.

6. Wide-mouth barrel urea solution filling machine adopts unique software and hardware design, which can effectively prevent material dripping and ensure the cleanliness of filling equipment and packaging containers.

7. This machine adopts programmable logic controller (PLC), touch screen operation control, and is convenient to use and adjust.

8. Each filling head is equipped with a weighing and feedback system, which can set and slightly adjust the filling amount of each head.

9. Advanced sensing elements are adopted to ensure that there is no barrel without filling. When the barrel is blocked, the host will automatically stop and give an alarm.

10. The filling mode is submerged, which can effectively reduce the generation of foam and meet the filling requirements of materials with different characteristics.

11. Each pipeline is connected in a fast way, which is convenient for disassembly and cleaning. The parts in contact with materials are made of high-quality stainless steel.

12. The structure of the whole machine meets GMP requirements, with stable performance, safety and environmental protection, and beautiful appearance.

Other supplier products

|

|

Mask packing machine |

Packaging machine _ automatic medical disposable mask packaging machinery and equipment packaging material: OPP/CPP/OPP composite PE/PET composite ... |

|

|

GZM-30AF Automatic Strong Acid Filling Machine |

The system is made of PLC programmable controller and touch screen, which is safe and reliable. Automatic barrel feeding, filling and discharging w... |

|

|

WH-5L-XY automatic filling machine |

Product parameter Using AC220V 50/60Hz power supply, the filling speed is 4-10mb/min (depending on the material flow rate). The filling accuracy of... |

|

|

beverage filling machine |

Feed Filling Machine _ Bottled Turtle Food | Cat Food | Dog Food Granular Filling Machine Filling speed: 10-20 bottles/minute Diameter of bottle: &... |

|

|

Automatic exhaust pressure cover filling machine |

1) Adopt European weighing technology. Set various packaging specifications. 2) Siemens programmable microcomputer controller is adopted Store more... |

All supplier products

Same products