Powder pneumatic valve pocket packaging machine

Powder pneumatic valve pocket packaging machine;

Product introduction:

This machine has a high degree of automation, simple operation, equipped with a newly developed automatic bag unloading device. It only needs workers to insert bags (adaptive valve pockets) to complete the packaging production process, saving labor (3-4 people), reducing the labor intensity of workers, greatly reducing production costs and improving production efficiency. Pneumatic valve port packaging machine is suitable for packaging powder or fine particles (≤5mm) with good fluidity, and it is powered by compressed air. Compressed air passes through the atomizer (air cushion) to fluidize the materials in the closed container, thus achieving the function of feeding. The closed pneumatic rubber valve is adopted, and by controlling the flow area of the valve, the feeding amount of the packaged materials can be controlled, and the effective and stable packaging accuracy and speed can be realized. The production line can produce a variety of dry powder products: thermal insulation mortar, bonding mortar, anti-cracking mortar, dry powder binder, self-leveling mortar, dry powder putty and other dry powder materials.

Main features:

1. Full-automatic microcomputer control, intelligent automatic identification and automatic measurement, high sensitivity, stable performance, strong anti-interference ability and accurate weighing;

2. The brand-new design has no mechanical weighing mechanism such as gate, balance beam, weight, clamping wheel, clamping pin, tension spring, pulling spring, etc., thus infinitely reducing wearing parts; Not only reduces the maintenance cost, but also improves the production efficiency;

3. It can automatically realize the functions of pressing, filling, closing and dropping the packaging bag, with stable performance and simple operation;

4. The machine body is completely sealed and equipped with a dust removal port, which is reasonable in structure and durable, and truly realizes environmental protection production;

5. The packaging machine mainly has two models: single-mouth (GZM-AI) and double-mouth (GZM-AII), and the 4-6-mouth packaging machine can be formed by juxtaposing two mouths.

Technical parameters:

1, the output per mouth is 10-15t/h, 2, the error of bag weight is ±0.2kg, 3, the qualified rate of bag weight is 99%, 4, the power per mouth is 0.5kw,

5. Weight of single bag: 10-50kg (can be set according to requirements).

Other supplier products

|

|

Granular valve port packaging machine |

Granular valve port packaging machine I. Scope of application Quantitative packaging of granular materials in the industries of feed, grain, chemic... |

|

|

Bagged butter and jelly filling machine |

Bagged butter and jelly filling machine yb-1 automatic liquid packaging machine Main uses: This automatic liquid packaging machine is suitable for ... |

|

|

GZM-9000B automatic bottle sorting machine |

Main technical parameters main feature This machine is a full-automatic bottle sorting machine, which is suitable for the previous filling process... |

|

|

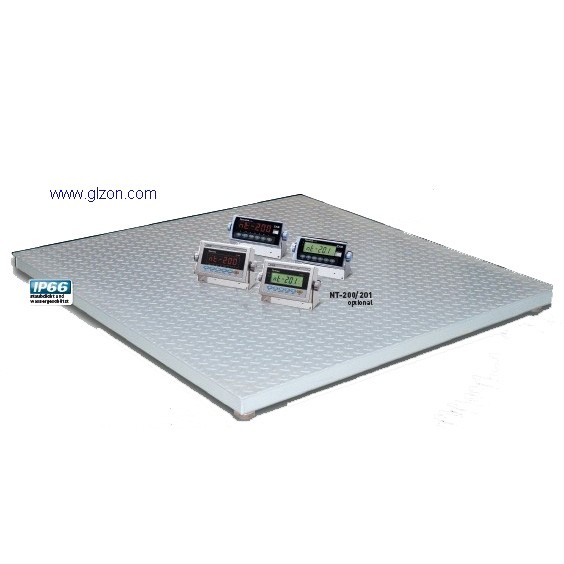

Explosion-proof floor scale |

The explosion-proof scale can take 4-20mA output. GZS-EX2 frameless electronic platform scale is a newly designed yi compact electronic platform sc... |

|

|

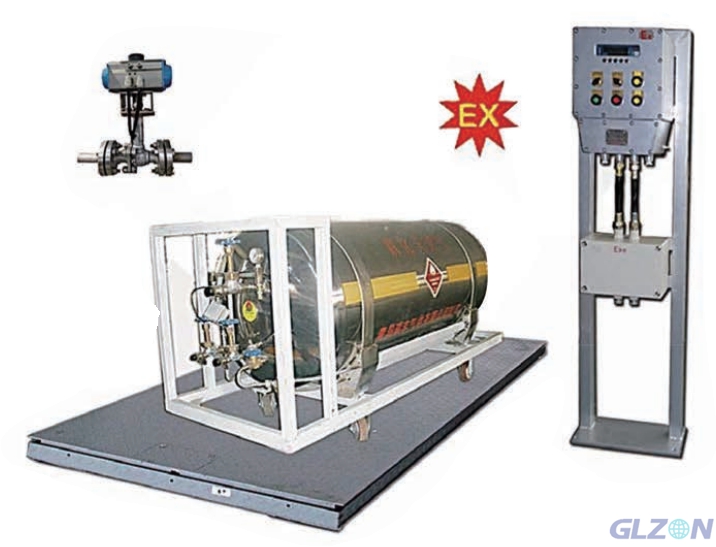

GzM liquefied gas filling machine |

Applicable: The quantitative filling system of LNG, night chlorine and liquefied gas is made by PLC, which is safe and reliable. The filling head a... |

All supplier products

Same products