Pipe Welding & Cutting Machines

What is Plastic Welding and What is Plastic Welding Used for?

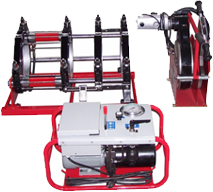

Pipe welding machines & cutting machines are necessary for metal pipe procedure. The pipe cutting machine can cut plastic pipe fittings into different angles according to the needs of customers. The cutting angle is up to 67 degrees, using the Swedish saw blade and limited switch for safety. They are usually used for the production of Bends, Tees, Cross, Y welding fittings, and other fabrications. Pipe welding machines are suitable for HDPE/PP pipes and fittings, with high-quality aluminum casting without compromising strength and performance, high quality design provides for welding on the work site and at the factory.

Why Choose Plaswelding as Your Plastic Pipe Welding Machine Supplier?

Plaswelding is a professional industrial welding machine manufacturer & supplier that can provide various kinds of reliable plastic pipe welding machines and cutting machines. As one of the leading plastic welding machine suppliers in China, we have our own factory and own a wide range of plastic pipe welders for sale including plastic pipe welders, PVC pipe welding machines for pipes, etc. If you want to get more information, please contact us now and get an attractive plastic welding machine price.

What Plastic is Used for the Welding Machine for Plastic Pipes?

The plastic pipe welding machine is used to weld pipes made from PE, PP, and PVDF and can not be used to weld material without the description here, otherwise, the machine may be damaged or some accident may be resulted.

PE Material

Polyethylene is a thermoplastic resin prepared by polymerization of ethylene. In the industrial field, it also includes the copolymer of ethylene and some types of α-olefin. Polyethylene is odorless, non-toxic, feels like wax, and has excellent low-temperature resistance, and good chemical stability, it can also withstand the erosion of most acids and bases. Polyethylene is insoluble in general solvents at room temperature, and it has low water absorption and excellent electrical insulation.

PP Material

Polypropylene is a polymer formed by the addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. Its melting point is 189 ℃ and the temperature range is -30mm 140 ℃. It is widely used in the production of fiber products such as clothing, blankets, medical devices, automobiles, chemical containers, etc., as well as food and drug packaging.

Open the frame and take out the heating plate and close two melting ends as quickly as possible.

Keep the bar of direction valve in the close position for 2~3 minutes, put the bar of direction valve in the middle position, and press the button (“T5”) to count the cooling time until it is over.

Difference Between Plastic Welding And Fusion Welding

Plastic welding refers to the connection method that the contact surfaces of two plastic parts are fused at the same time by heating so that they are combined into a whole. Only applicable to thermoplastic connections. Welding rods can be used or not used during welding. When using the welding rod, the end face of the end to be welded shall be made into a fixed shape (such as U-shaped, X-shaped, etc.) joint, and the molten body of the welding rod drips into the joint, and the two welded parts are connected as a whole; When the welding rod is not used, the welding surface shall be heated and melted, and then the vertical pressure shall be applied to the welded surface until it is tightly fused.

The so-called fusion welding machinerefers to the melting of the welded joint under the action of high temperature during the welding process. Since the welded parts are closely attached together, under the action of temperature field, gravity, etc., without pressure, the molten liquid melted by the two workpieces will mix. After the temperature decreases, the molten part condenses, and the two workpieces are firmly welded together to complete the welding method.

As one of the most professional plastic pipe welding machine suppliers, we provide fusion pipe machine, fusing machine for pipe, large welding machineand etc. Want to know automatic pipe welding machine priceor more? Contact us.

Send product request

Other supplier products

| Saddle Welding Machine | Features of Saddle WeldingMachine LHA serial saddle welding machinecan fabricate the reducing tee welding fittings in PE, PP, or other thermoplast... | |

| Hydraulic Butt Welding Machine | Features of Hydraulic Butt Fusion Welding Machines Removable PTFE coated heating plate with high accurate temperature control system; Electrical ... | |

| Hydraulic Butt Welding Machine | Features of lRemovable PTFE coated heating plate with high accurate temperature control system; lElectrical planning tool; lBe made of lightw... | |

| LHM 160 Manual Butt Welding Machine | LHM Series Manual poly pipe welding machineare suitable for PE & PP pipes and fittings on the building site and in the factory, with high-quali... | |

| LHM 160 Manual Butt Welding Machine | LHM 160 Manual Butt Welding Machine LHM Series Manual poly pipe welding machineare suitable for PE & PP pipes and fittings on the building sit... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |