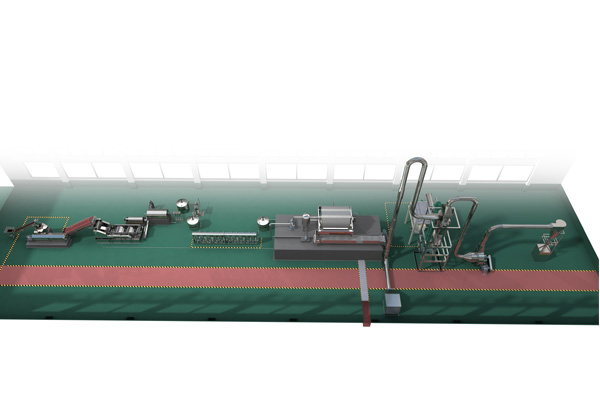

China Potato Peeling Machine

With the development of food industry, food deep processing has been paid more and more attention by the world, especially in the birth of instant meals and convenience foods , which has promoted the rapid development of fresh and dehydrated vegetable industry and requires the deep processing of raw materials to accompany the development. Among them, the deep processing of potatoes is one of the industries that people attach great importance to and develop rapidly. Potato china peeling machine is also more and more widely recognized and used. How to better use the chinese potato cleaning machine, to maximize the effectiveness of the machine, should not only use correct methods, but also be regularly maintained and having maintenance.

First, potato peeling process/potato peeling machine

Potato peeling process: cleaning→ peeling→ cleaning.

1 cleaning

The purpose of cleaning is to remove soil and impurities on the surface of potatoes. In production practice, potatoes can be transported to the washing machine through the flow tank. On the one hand, the flow tank plays a transport role; on the other hand, potatoes can be soaked and roughly washed. The washing machine can choose the blower type, depending on the air stirring and the friction of the drum, accompanied by high-pressure water spraying to clean potatoes.

2 Peeling

Friction peeling: When the potatoes are put into the barrel of the china peeling machine, the rotating dial constantly turns the potatoes and rubs the potatoes to peel. Potato peeling efficiency is higher because of the constant collision and friction on the barrel wall. At the same time, rinse the worn skin with a flushing pipe, and the dirt will flow out with the water through the drainage outlet.

3 Re-cleaning

Wash off the dandruff and proceed the next step.

Send product request

Other supplier products

| Cassava Drying Machine | Features of Cassava Drying Machine Processing Capacity: 100-2000Kgs/hourApplication Scope: Cassava starch and flour dryingProduct Introduction: Air... | |

| Garri Processing Machinery | Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a sta... | |

| Fufu Machine | Features of Fufu Machine Fufu making machine for sale- Make Fufu(foofoo) from Fresh Cassava Fufu Machine Fufu Process Description and Flowch... | |

| Cassava Starch Extraction Machine | Features of Cassava Starch Extraction Machine Processing Capacity: 15-35Tons/hourApplication Scope: Crushing the cassava into the slurryProduct In... | |

| Hydraulic Dewatering Press | Features of Hydraulic Dewatering Press Processing Capacity: 100-500kgs/hour Application Scope: Cassava slurry dewatering Product Introduction: H... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |