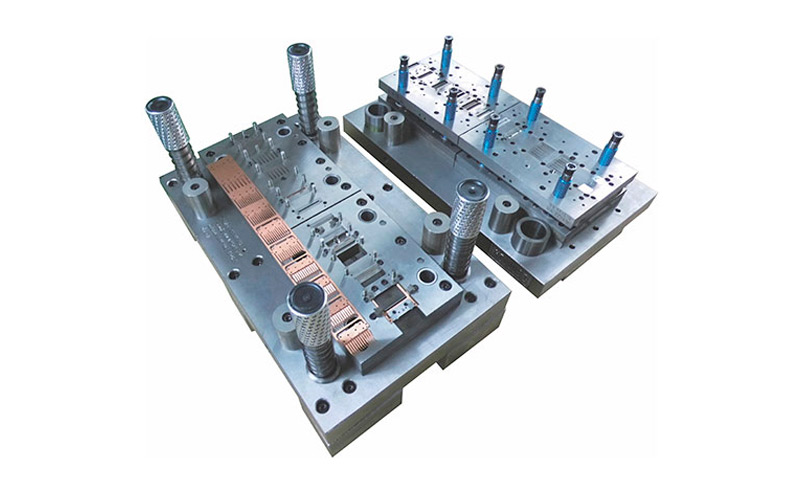

Progressive Die

Custom Progressive Stamping DieService China

Progressive diedesign(also known as continuous die) is referred to the punch in a stroke, in a few different positions, at the same time to complete the multi-process die.

OEM Progressive Die Factory

Stamping parts in the progressive die are gradually formed, continuous forming is the technique of work stage concentration, which can make cutting, grooving, punching, plastic deformation, blanking, and other processes completed in a pair of old. According to the actual needs of stamping parts, a number of stamping processes are arranged in a certain order (called the station in the progressive die) for continuous stamping. It can not only complete the blanking process but also can complete the forming process, even the assembly process, many complex stamping parts that need multi-process stamping can be fully formed on a die, which provides favorable conditions for high-speed automatic stamping. It can be seen that the progressive die is a kind of high-efficiency punching die with multi-stations.

Types of Custom Progressive Die Components

Progressive Die

Progressive Stamping

Progressive Die Stamping

Progressive Stamping Die

Progressive Die Design

Stamping layout design

The cost of progressive metal stampingproduction is mainly the cost of raw materials, so reasonable use of materials is a very important issue in stamping production. The arrangement of stamping parts on the steel strip or plate is called the stamping layout. If the layout design is not reasonable, it will cause material waste. To determine whether the layout is reasonable is mainly the utilization rate of reference materials, that is, the percentage of the actual area of the workpiece to the material area. The less the area of waste produced, the higher utilization of materials will be.

The discharging of stamping parts can be divided into three kinds of discharging methods: waste discharge, less waste discharge, and no waste discharge. It is significant to adopt the less or even no waste layout method to reduce the cost of stamping parts and is conducive to producing more products at the same time to improve production efficiency. Meanwhile, because of the reduction of stamping perimeter, the stamping die structure can simplify and pressure reduced. The material utilization rate can reach 95% with no waste discharge, and 70% to 90% with little waste discharge.

Progressive Die Design

Benefits of Progressive Die

Labor Productivity

A progressive die can complete blanking, bending, forming, drawing, and other processes. The press can punch one workpiece or a metal part per stroke, so it has higher labor productivity than single die and compound die.

Simple And Efficient

The use of progressive die stamping can reduce the number of equipment, molds, and workshop area, eliminating the transfer and storage of semi-finished products.

Automatic Continuous Die Stamping Process

Progressive die easily achieve automation from coil or strip material to feeding, discharging, and lamination. Because of the automatic continuous die stamping process, workers can safely operate without entering a dangerous area.

Benefits of Progressive Die

The Die Has Higher Strength And Longer Life

The processes of the progressive die are scattered in each station, and there is no "minimum wall thickness" problem as the composite die have, therefore this kind of die has higher strength and longer life.

Notes on Progressive Die

(1) Heat treatment: the quenching temperature, the tempering times and temperature time are inappropriate.

(2) Stamping stacking: sheet overlap is still stamping, usually for stripping board rupture.

(3) Waste blocking: the punch and the lower template are more damaged if the hold is not drilled or size is not consistent.

(4) Punch drop: not properly fixed or suspended, or screw too thin, or punch broken.

(5) Hole escape: the size or depth of hole escape of punch press plate is not enough, or the stripping plate is damaged.

(6) Foreign body entry: die parts collapse and fall may damage the stripping plate or plunger chip.

(7) Setting error: damage caused by wrong location and direction of parts.

(8) Spring factors: spring force is not enough resulting in the damage of overlapping punching parts.

(9) Improper stamping: peripheral equipment such as sending, putting, receiving machine damage,caused the damage by the abnormal press.

(10) Improper maintenance: the above points are caused by the failure to replace or the screw is not locked or restored according to its original state.

Key Design Points Of Multi-station Progressive Die?

When designing multi-station progressive die, designers should pay attention to the following design points.

① The working procedure should be arranged reasonably.

② To reasonably determine the number of stations and leave vacant stations.

③ Attention should be paid to the design of the layout diagram and the correct drawing of the layout diagram.

④ Perfectly guide material and floating roof device should be designed.

⑤ To design a reliable and stable unloading mechanism. According to different stamping properties, a discharge plate can meet the requirements of multiple functions.

⑥ To design an accurate distance structure.

⑦ The convex and concave die structure design should be reasonable.

⑧ There should be a reliable safety monitoring organization.

⑨ On the premise of satisfying the usage and certain life, we should pay attention to the manufacturability of mold structure design, economical materials, convenient processing and maintenance, and reduce the manufacturing cost of the mold.

As professional progressive die factory, we can offer kinds of related products for sale, if you have needs, please contact us.

Send product request

Other supplier products

| TPN-FP001Portable Charcoal Fire Pit | Custom Portable Charcoal Outdoor Germany bonfire barbecue fire pit camping Features of TPN-FP001Portable Fire Pit Stainless Steel Season:All-Se... | |

| Firewood Splitter Tool | Firewood Splitter Tool Toposon provide effective tool on hardwood, dry wood and can cut quickly. Toposon's Splitter Tool uses ultra durable high-c... | |

| 17 Inch Kettle BBQ Charcoal Grill | Heat Control 17 Inch Kettle BBQCharcoal Grill for Tailgating, Camping, and Outdoor Picnics with Steel Cooking Grate. Features of 17 InchCharcoal... | |

| Stove Pipe Thermometer | This is the best seller's wood stove pipe thermometerin the past few years. The wood stove pipe thermostatcan be sold with a stove fan or individua... | |

| TP21-PC-C2 Manual Wood Splitter | hand powered log splitter. Features of TP21-PC-C2 hand operated log splitter Application: Wood Splitting Mounted Usage: Wood splitting... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |