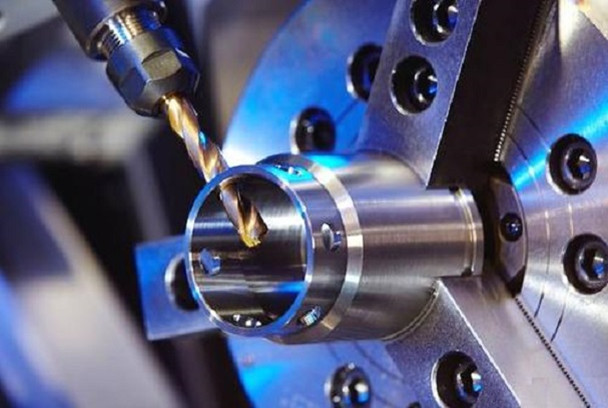

CNC Boring

CNC boringis used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After welding the accessories, use CNC horizontal boring and milling equipment to process both sides with a concentricity of 0.05mm.

CNC Boring Capabilities

CNC horizontal milling and boring machine are suitable for machining large and medium-sized parts and box parts rough and fine boring, milling, and other processes. The worktable is equipped with 4x90 ° optical positioning device, which can meet the requirements of large parts turning. The CNC horizontal milling and boring machine are suitable for the hole and plane processing of box parts with many processes, turning of a cylindrical surface, cutting of annular groove in the hole, tapping of male and an English screw thread with a tap, etc. It also has the technological functions of the rectangular coordinate system, polar coordinate system and contour processing of CNC machine tool. The CNC horizontal milling and boring machine is a high-efficiency and precision technique of advanced precision cnc machining China.Because the CNC horizontal milling and the boring machine have high rigidity and closed-loop detection system, which can meet the requirements of rough and fine machining.

Advantage of CNC Boring

CNC boring and milling machining has the characteristics of strong rigidity, high machining accuracy and efficiency, good stability, long transverse travel, large bearing capacity and powerful cutting. CNC boring and milling machining is a kind of extreme precision machining. It is especially suitable for the boring and milling of the large planes and the finishing of large box parts and hole series. In addition to drilling, boring, expanding and reaming, various accessories can also be used for turning, milling and screw pattern processing.

As one of machining manufacturing companies, we can offer high quality and precision cnc machining chinafor clients, anything you need, please contact us.

Send product request

Other supplier products

| Industrial Machining and Manufacturing Services Application | Industrial Machining and Manufacturing ServicesApplication ETCN has experience in cooperating with companies in various fields, relying on a compl... | |

| Precision Machining | As a precision machining cnccompany of china, ETCN offers cost-effective precision machining solutions whether you need a single part, a batch of p... | |

| Cutting | Sheet Cutting Sheet metal cut out is used for air compressor equipment support frame after bending, laser cutting long round hole and welding hexa... | |

| Bending | As a cnc machining service supplier, ETCN offers a quality CNC me metal folding/bending press after laser cutting which is used for the base of the... | |

| CNC Turning | The parts processed by precision CNC lathe have the characteristics of good stability and high precision. The added powerhead can complete the mach... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |