BGA Rework Station

Zhuomao BGA rework station is one of the best BGA rework station suppliersin China. First of all, what is BGA machine? BGA rework/repair station is what we called ball grid array rework station, also abbreviated as BGArs. BGA is a chip packaging technology, which is applied to improve the performance of digital products and reduce the volume of products through the ball grid array structure. All digital products through this BGA machine Chinatechnology will have common characteristics, that is, small volume, strong performance, low cost, and powerful function. BGA rework machine is the exact equipment used to repair BGA chips. According to the operation requirements, we have launched different BGA rework machines that enjoy a good reputation from our clients all over the world recently. -

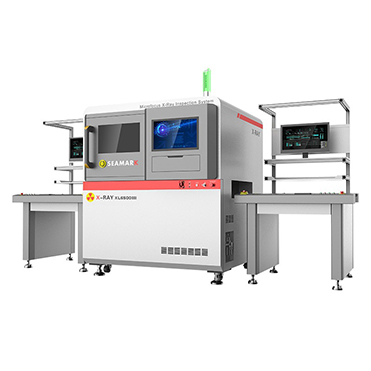

Now, we are providing the best ball grid array rework station including manual, semi-automatic, and fully automatic BGA repair station and workstation for PCBA repairing; microfocus BGA Xray inspectionmachines, such asChina inline X ray machine, online X-Ray inspection machine, 3D/CT X-Ray inspection machine; Online& offline SMD X-Ray reel counter and SMD smart storage systems, such as smart storage rack, smart storage tower, and smart storage warehouse. This diversified BGA machine for motherboard ranges with reasonable price and technical support enables us to help more and more EMS companies could use higher-level automation production equipment.

As one of the professional BGA Rework Station manufacturersfrom China, Zhuomao promises to provide the best BGA rework station machine to our customers. We have various BGA rework stations for sale with good quality. If you want to get the BGA rework station machine price list or have any other questions, please contact us as soon as possible.

Types of BGA Rework Station Machine For Sale

ZM-R5860 Hot Air BGA Rework Station

ZM-R5860 Hot Air BGA Rework Station Chinais a kind of rework station provided by Zhuomao, which has many features and special functions.

ZM-R7220A Infrared Soldering Station

ZM-R7220A is an intelligent IR BGA Rework Station with real-time temperature monitoring, optical alignment system, rapid heating, and cooling.

ZM-R720A LED/Micro Component Rework Station

ZM-R720A micro/mini BGA rework station is a precision optical intelligent BGA rework station suitable for the rework of precision micro devices.

ZM-R730A Large Board BGA Rework Station

HD Optical Alignment and Intelligent ControlEquipped with automatic feeding device, using Panasonic PLC and high-precision temperature control module, high-precision K-type thermocouple, dynamic PID

ZM-R7830A Smart Optical BGA Rework Station

R7830A is an optical alignment automatic rework equipment, which also works as a laser SMD rework station.

ZM-R7850A Smart Optical BGA Rework Station

R7850A is an optical alignment automatic rework equipment, equipped with multi-functional control features, convenient temperature setting and storage, bottom heating system, etc.

ZM-R8650 Fully Automatic BGA Rework Station

R8650C is a fully automatic visual alignment BGA rework station, suitable for automatic visual placement of various chip devices on large PCB boards (such as 5G communication boards), automatic welding.

ZM-R8000B Large Precision Rework Station

R8000B is a large-scale precision rework station, self-tuning temperature curve, large-area preheating platform, automatic feeding and adsorption, high-performance, multi-loop heating system.

ZM-R8000D Large Precision Rework Station

R8000D is an ultra-large high-end optical alignment precision rework station, suitable for rework of 5G server and large server mainboards.

ZM-R9000 Super Large Board Disassembly Preheating Platform

R9000 super large preheating platform is suitable for the rework of surface mounting devices for 5G and other large servers.

What is BGA Rework Station Machine?

The BGA rework station, as the name suggests, is a machine used to rework BGA. BGA is a sealed chip. If there is a bad BGA on the production line, this machine needs to be used for rework. The BGA repair station for mobile adopts an integrated design of BGA device removal, placement, alignment, and soldering. It is suitable for the repair of BGA, CSP, POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames, modules, and other components on PCBA substrates such as servers, PC motherboards, tablet computers, and smart terminals.

How does a BGA Rework Station work?

The working principle of the BGA soldering station is to use artificial intelligence (AI) technology to set a good temperature curve, and through the temperature control system, to achieve high-precision inspection and monitoring of the process of disassembly, soldering, and assembly of the BGA chip rework. The high-end SMD BGA rework system has a visual high-definition automatic alignment function. After the PCB board and BGA, images are captured and positioned by the CCD, the image processing software analyzes and automatically corrects the deviation to achieve precise alignment and placement. The repeat placement accuracy can reach ± 0.01mm. The upper heating device and the placement head realize fully automatic identification of the placement device and placement height and have the functions of fully automatic alignment, fully automatic mounting, fully automatic soldering, and fully automatic desoldering. After knowing the working principle of the BGA rework equipment, you may want to bulk buy the perfect BGA SMD rework station for your electronic equipment repairing. If you want to purchase at a reasonable infrared soldering station price, please contact Seamark ZM first.

FAQ of BGA Rework Station Machine

How to choose a BGA rework machine?

There are some factors that need to be considered when you want to buy BGA rework machines.

Type selection

Generally, there is the hot-air rework station machine and infrared/IR rework station machine. The hot air repair station obtains the heat required for reflowing BGA Solder by blowing hot air onto the circuit card. IR BGA repair station has an infrared lamp that can receive infrared light for heating BGA components to the reflux point.

The hot air rework station has been on the market for a longer time, so technicians may be more familiar with this type. Hot air systems are also generally cheaper than IR BGA rework stations. Its disadvantage is that it is difficult to shield the surrounding components. There is a noise problem. If properly designed, the IR rework station can well locally heat BGA components. The infrared station has an additional advantage, that is, the structure is not complex and easier to maintain. When selecting an IR repair station, pay attention to discrimination. It uses infrared to work, rather than infrared as a decoration.

Temperature Control

The best BGA equipment will provide accurate, closed-loop, digitally controlled temperature. For example, the ZM R5860 BGA machine is perfect for temperature control.

Work Area

There are two points to note. First, the size of the work area will determine how large circuit cards the BGA workstation can handle effectively. Secondly, the installation style of the slide rail. Generally, the installation guide rail is adjusted on at least one axis, but there will be multiple adjustments in the high-end SMT rework station. This will make it easier to capture and hold circuit cards with complex shapes.

Apart from these three factors, you need to find some reliable BGA rework station manufacturers. After you choose a reliable manufacturer, you should consider the BGA rework station price. To get good quality machines at a reasonable price. Contact Zhuomao immediately!

Send product request

Other supplier products

| ZM-R7850A Smart Optical BGA Rework Station | R7850A PCB smartopticalBGA soldering desoldering stationmachine is an optical alignment automatic rework equipment. This BGA Soldering Machine has ... | |

| XB8100 X-Ray Lithium Battery Inspection Series | XB8100 SMT AOI (automated optical inspection) Machine is mainly used for automatic online detection of positive and negative alignment during the p... | |

| X7600 Offline X-Ray Inspection Machine | X7600inspection machine adopts the world's top Japanese Hamamatsu X-ray source. This industrial X-Ray machine can easily distinguish the semiconduc... | |

| Offline X-Ray Inspection Machine | Seamark's 2D industrial x ray machine adopts a closed microfocus X-ray tube with voltage 90KV, 110KV, and 130KV, which meet different product inspe... | |

| Inline X-Ray Inspection Machine | In the inspection process of electronic components, the PCB seamark x rayinspection machine can be directly connected to the SMT production line fo... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |