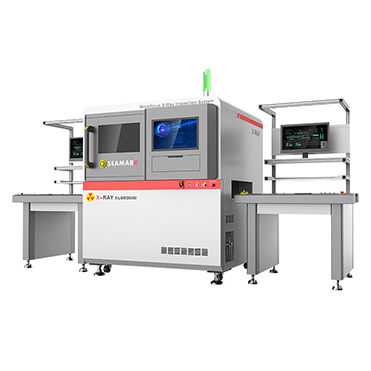

X5600 Offline X-ray Inspection Machine

X5600is a small precise microfocus X-Ray inspection equipment, suitable for R&D enterprises, laboratories, quality inspection rooms, etc. It is the first choice for bga x ray inspection equipmentof small parts.

IC chip xray wafer inspectionmachine is a piece of non-destructive testing equipment especially for prospective testing of internal defects of IC chips. It is one of the best ways to detect defects of IC chips. The X-ray detection equipment mainly relies on the internal X-ray tube to emit X-rays to irradiate the IC chip for imaging. After the X-rays penetrate the object, the digital tablet receives the image signal and then transmits it to the computer. After software processing, it will image in real-time on the screen. X-ray testing belongs to the category of nondestructive testing for IC chips. The tested samples can be put into use again, which can effectively save the production and inspection cost.

Functions of X5600 Offline X-ray Inspection Machine

00 Automatic Void Ratio Calculation

Enhanced BGA inspection function

X5600 industrial X-ray inspection machine can quickly select and mark a single solder ball, or select the solder balls to be inspected by matrix box; it can manually or automatically identify BGA solder balls and complete the inspection. Follow the system guidelines to easily complete the inspection process and ensure accurate and reliable inspection results.

01 Size Measurement

Measuring tools

Distance, distance ratio, lines distance, angle, arrow mark, circle radius, point distance, circle centres distance, circumference, hand-drawn polygon, hand-drawn freeform, etc. can add a text description.

02 Defect Inspection

Automatically detect defects

X5600 can automatically detect the size, area, broken wire, bridging, etc.

Customizable image algorithm

Customerized software algorithms based on product features and request to achieve fully automatic defect inspection algorithms, including Y/N, crack, broken wire, offset size, and quantity, etc.

03 CNC Inspection

CNC automatic operation inspection

X5600 supports CNC multi-point automatic inspection mode, based on product feature set multi-point coordinates for automatic inspection.

The automatic CNC operation detection

Automatically save images, generate reports, also support batch inspection.

04 Tilt/Rotate Function

Tilt angle inspection function

The X5600 detector produced by Zhuomao supports a tilt angle of ±30°. For cases where the photo taken on the front of a special device cannot identify the defect feature, the tilt function can be used to observe the device features at multiple angles, making it easier to analyze and identify the defect.

360° Rotating photo inspection function

Equipped with a rotating manipulator that can rotate 360 degrees to take images, no dead angle for defects observation.

Advantages of X5600 Offline X-ray Inspection Machine

Miniaturized equipment, easy to install and operate.

Applicable to Chip, LED, BGA/CSP, Wafer, SOP/QFN, SMT and PTU packaging, Sensors, Connectors, and Precision Castings inspection.

High resolution design to get the best image in a very short time.

Infrared automatic navigation and positioning function can select the shooting location quickly.

CNC inspection mode which can quickly and automatically inspect multi-point array.

Inclined multi-angle inspection makes it easier to inspect sample defects.

Simple softwareoperation, low operating costs.

Long lifespan.

Drawing Of X5600 Offline X-Ray Inspection Machine

Safety Considerations Of X5600 Offline X-Ray Inspection Machine

Obtained an exemption record from the Ministry of Ecology and Environment of the People's Republic of China

The X5600 obtained the certification document (sixth batch) for the exemption record of radioisotope and ray device of the Ministry of Ecology and Environment, with the record number [Yuehuan [2018] No. 1688]. The radiation device using this product model of our company can be exempted from the radiation safety license.

Safety Protection Design

According to the "Ionizing Radiation Protection and Radiation Source Safety Basic Standards" (GB, the radiation protection exemption standard is ≤1uSv/h, the design standard of this product is ≤0.5uSv/h, it is equivalent to 1/10 of the amount of radiation in the natural environment.

Components Multiple Safety Protection

Equipped with OMRON's safety control element, triple safety protection sensor, and direct connection control method with ray source, it fully complies with CE specifications and SEMI S2/S8 specifications of the semiconductor industry.

Now the price of automatic reballing machineis low, anything you need, please contact us.

Send product request

Other supplier products

| Offline Reel Counter | The offline counting machine is a micro-focus X-Ray automatic counting machine. This China inline x ray machineuses the X-RAY perspective princi... | |

| X-ray Inspection Machine for Stacking Battery | Seamark stacking battery industrial digital x ray inspection systemsare suitable for the inspection of stacking (blade) process-type cells in the l... | |

| Offline X-Ray Inspection Machine | Seamark's 2D bga x ray inspection equipmentadopts a closed microfocus X-ray tube with voltage 90KV, 110KV,130KV, which meet different product inspe... | |

| Inline X-Ray Inspection Machine | In the inspection process of electronic components, the pcb x ray inspection machine can be directly connected to the SMT production line for high-... | |

| Online X-Ray Inspection Machine | In the inspection process of electronic components, the pcb x ray inspection equipment can be directly connected to the SMT production line for hig... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |