HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB

The machine tool bed adopts "mineral casting" material and technology of Germany, which guarantees DEED CNC machine tool with better performance on accuracy maintenance and stability for a longer time. DEED CNC model HP800-WC is mainly used for turning to machine of 12-22inch passenger car wheel and truck bus wheel, also can be used for turning of similar disc parts.

FEATURES OF HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB

*Mineral casting rectangular hard rail bed has good seismic resistance, small thermal sensitivity coefficient, and good overall rigidity.

*Mineral casting spindle box has small vibration, high speed, and high efficiency, which is about 30% higher than the market average.

*According to the needs of the industry, specially ordered imported spindle units for machine tools.

*Automatic door structure, less time to open and close the door (within 2S).

*The chip conveyor is separated from the water tank, which makes cleaning and maintenance more convenient

*More reasonable internal layout and strong cooling of flushing chips to avoid chip accumulation without manual cleaning.

*The extreme ingenuity design brings a more convenient operation and clamping experience.

BENEFITS OF HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB

Mineral casting 45°slant bed. -The maximum length of embedded parts is 1750mm.

45 steel hardened with hardness HRC52 ~ 61.

During assembly, the accuracy of the linear guideway rail is less affected by temperature.

The bed is stable with minimal vibration.

The diameter of embedded parts reaches Φ 400mm.

Compared with iron casting HT300, mineral casting the vibration amplitude during machining is reduced by 20%.

For a 9.0x22.5 inch truck and bus wheel, rough and finish turning speed can be stable at 1000 pm.

Φ160 combined bearing. -High precision and rigidity.

Multi-wedge belt drive reduces the influence of the belt on high-speed rotation accuracy. -Multiple sealing structures to prolong service life.

HOW DOES HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB WORK?

CNC horizontal turning machining center adopts brake belt brake, which is mainly composed of brake wheel, brake belt, and lever. In the brake device, the brake wheel is a steel disc connected with the shaft by splines. A layer of steel mesh asbestos is fixed on the steel brake belt and the inner side to improve the friction coefficient. One end is linked with the spindle box, and the other end is fixed on the upper end of the lever. The brake belt of the horizontal lathe can be adjusted. The brake belt can be placed and adjusted by directly loosening the screw connecting the brake belt and the spindle box. When the CNC horizontal turning is adjusted properly, the brake belt can be released when the spindle rotates, but when the clutch is released and the horizontal lathe is stopped, the brake belt holds the brake wheel tightly, so as to realize the rapid stop of the spindle and achieve braking.

WHAT IS AN HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB USED FOR?

DEED CNC Horizontal Turning CenterHP800-WC for wheel machining application: Passenger car wheel, truck, and bus wheel machining first procedure, a second procedure, finish turning to the machine. After the coating of some passenger, wheels is completed, the "finish turning" process is required for side A (front). According to different processes, it can be divided into the following "finish turning": bright surface, super-bright surface, sub mirror surface, and mirror surface. The general criteria for evaluating the "finish turning" ability of wheel machining machine tools: clear and uniform lines, high finish, no light, and dark lines, no over cutting, etc.

HORIZONTAL TURNING CENTERSPECIAL FOR WHEEL HUB SPECIFICATION

HTC800/HTC900

|

Feed |

Maximum rotation diameter |

φ850 mm |

|

Maximum wheel diameter |

22" inch |

|

|

Maximum length wheel |

12" inch |

|

|

X axis travel |

-30~370mm |

|

|

Z axis travel |

850mm |

|

|

X/Z axis rapid traverse |

20/20 m/min |

|

|

Spindle |

Spindle max speed |

2500 rpm |

|

Spindle power |

30/37 kW |

|

|

Spindle torque |

375 N.m |

|

|

Spindle nose specification |

A2-8 |

|

|

Spindle neck |

φ160 mm |

|

|

ATC |

Tool quantity |

8 |

|

Inner diameter tool size |

φ50 mm |

|

|

Maximum outer diameter hilt size |

32*32 mm |

|

|

Adjacent tool change time |

||

|

Screw |

X-axis |

φ50*P10 mm |

|

Z-axis |

φ50*P10 mm |

|

|

Precision |

X-axis positioning |

|

|

Z-axis positioning |

||

|

X-axis repeatability |

||

|

Z-axis repeatability |

||

|

Others |

X/Z axis servo motor power |

4/4 kW |

|

X/Z axis servo motor torque |

22/22 N.m |

|

|

X/Z servo motor max speed |

3000 rpm |

|

|

Cooling water tank capacity |

600 L |

|

|

Machine size(not including chip conveyor) |

4169*2150*2147 mm |

|

|

Machine net weight |

11 T |

|

|

Control system |

FANUC 0i-TF |

As one of the cnc machining center manufacturers, we provide machining center in cnc, horizontal turning lathe, cnc machinery for saleand etc. For more information, please feel free to contact us!

Send product request

Other supplier products

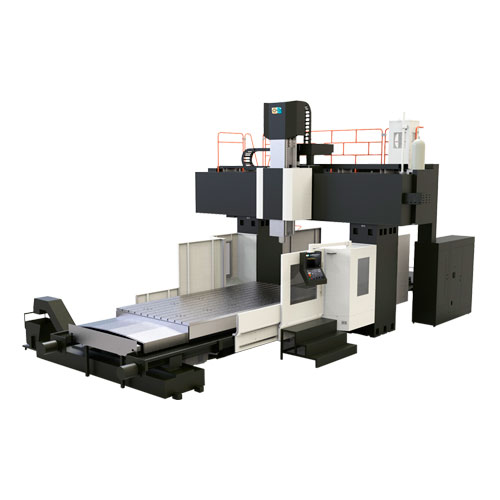

| GL-SERIES GANTRY MACHINING CENTER | Gantry Milling machine GL series has an Excellent high-rigidity structure and Cost-effective full-stroke machining tool. According to different Y-a... | |

| HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE | HBC Series is our CNC horizontal boring machine. According to the different sizes, we have HBC1116 CNC horizontal boring machine and HBC1316 CNC ho... | |

| HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE | HBC Series is our CNC horizontal boring and milling machine. According to the different sizes, we have HBC1116 CNC boring machine and HBC1316 CNC h... | |

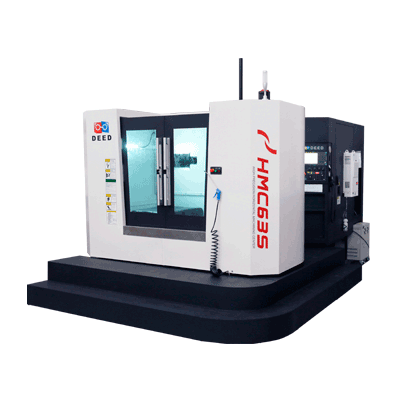

| Horizontal Machining Center For Sale | single station CNC horizontal machining center is suitable for various heavy cutting and high precision machining fields CNC HORIZONTAL MACHI... | |

| HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER | DEED horizontal machining center with pallet changermainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcyc... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |