High Speed Roofing Tile Making Machine

The high-speed metal roof tile machine is for continuously roll forming and pressing step tilessheets. Thesteplength of this series can be set up andthe depth of each step is adjustable. Its productionspeed of this series is about 8-10m/min. Similar to otherwall sheet roll forming machines, this high-speed roof tiling equipment is also certified with multiple patents. In addition, prompt delivery is also available.

Raw Materials forroof tile rolling machine

Material type: Color coated Steel, Aluminum sheet

Thickness: 0.4-0.6(mm)Yield Strength: 230-350 MPa optional

Width: 1200/1220/1250(mm)

Production Line Components and Parameters ofRoof Tile Machine

1.Decoiler 5t/8t/10t/15t Motor/hydraulic motor/passive (optional)

2.Filming covering device optional

3.Front shear optional

4.Lubricating device no need

5.Roll forming system individual standing column structure

6.Safety cover optional

7.Step pressing unit Step length, depth, head & end length is adjustable

8.Post cutting hydraulic

9.Output System Manual supporter/ Automatic Stacker (optional)

Stackmaster (Output direction) Lateral/Longitudinal (optional)

10.Hydraulic system Power supply for decoiler /post-cutting system

11.Electric control system MITSUBISH/ SIEMENSE/AMS (optional or as requested)

Step Roof Tile Line Layout

The working flow of ourtile roof machine for sale usually goes as follows: Coil Charging Car(optional) - Decoiler(passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System

Advantages Of Tile Roof

Metal Roofing tiles perform the elegant style of traditional roof tile and suit every architectural design. What's more, it is much more convenient and takes a shorter time for installation.

Roofing Tile Drawings

Finished Roofing Tiles by High-Speed Roof Tiling Equipment

Specifications ofRoof Tile Machine for Sale

Machine Condition Fully New,A Grade quality

Panel Shape As profile drawing and customer’s requirements

Operator needed 1-2 persons

Power Supply 220V/380V/415V/460V, 50/60Hz, 3P (as requests)

Equipment Weight About 15t

Dimension (L*W*H) about 25*3*2m

LOADING SIZE Normally need 1x 40' (+ 1x 20GP) container.

Equipment Color Normally Blue/White, or as requests;

Place of Origin Zhejiang, China (Mainland)

Packing Standard and careful export packing

As a professional roll forming machine factory, we provide roll forming equipment, coil upender, roof tile production machines, metal roof tile making machine, corrugated roof tile making machine, roof tile roll former, pipe mill for sale and etc. For roof tile forming machine price, contact us.

Other supplier products

|

|

Double Side Manual Decoiler |

Specifications ofDouble Side Manual Decoiler

Type

Double side

Capacity

2t/2.5t/3t/5t/8t is optional

Extensio... |

|

|

Direct Square Tube Mill Line |

Direct Square Tube MillLine is mainly used to produce the square and rectangular tubes directly, from square to square or rectangular to rectangula... |

|

|

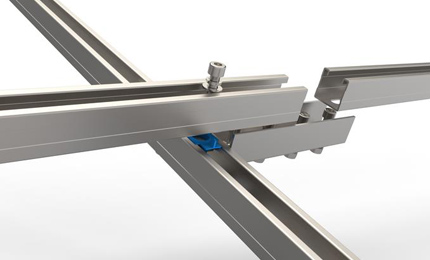

Solar Photovoltaic Support Rolling Machine |

SOLAR PHOTOVOLTAIC SUPPORT ROLLING MACHINE

Double-in-roll c-shaped steel photovoltaic bracket is mainly applicable to the ground photovoltaic po... |

|

|

Stainless Steel Tube Mill Line |

STAINLESS STEEL TUBE MILL LINE

Stainless still tube millLine is specially used for producing stainless steel straight seam welded pipe. It is ma... |

|

|

Cut To Length Line |

Function of Cut To Length Line

It is used for cutting steel coils into certain length sheets.

Technical parameter of decoiling machine cut to l... |

All supplier products

Same products