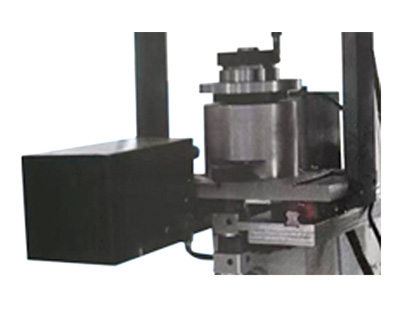

STAINLESS STEEL ANGLE PRESSING MACHINE

Fully automatic pot cover stainless steel angle pressing machine is an automatic line for glass cover production, which is an indispensable process. It has the advantages of high efficiency, high quality, high energy saving, low cost, simple and convenient operation, and wide application range. It is an ideal equipment for the glass cover industry and other kitchenware production industries.

HOW DOES STAINLESS STEEL PRESS MACHINEWORK?

After the stainless steel band of the glass pot lid is crimped and stretched, the angle pressing process is an indispensable process in the automatic line industry of the kitchenware industry. At present, the equipment is widely used in the processing and production of the glass pot lid G-ring and T-ring. The equipment adopts touch screen digital input to control the operation settings, which is simple and convenient to operate, and it is easy to replace the product.

ADVANTAGES OF STAINLESS STEEL ANGLE PRESSING MACHINE for sale

1

Fully automatic angle press is an ideal special equipment specially designed and manufactured. The device has a wide range of applications and adopts touch screen digital input to control the operation settings, which is simple and convenient to operate and easy to replace.

2

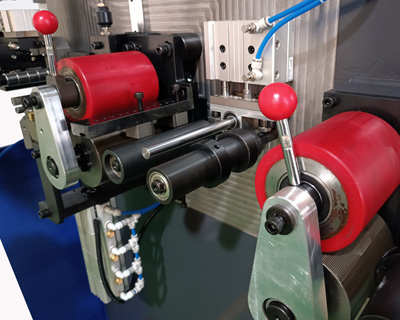

Equipment accessories (panel rack, control system, drive motor, pneumatic components) are world-renowned brand products. The equipment adopts a programmable controller as the main control unit, with simple circuit, high integration and intelligence, which reduces the failure rate and facilitates maintenance and maintenance.

3

The steel ring that has passed through the edges is squeezed by the corner pinch rollers to achieve the effect of squeezing the edges together and pressing the corners against the upper surface. In addition, it is equipped with a high-precision planetary reduction device, which can improve the positioning accuracy of the product.

As one of the most professional punch press machine manufacturers, we provide automated laser welding machine, stainless steel welding machine, pressing machine video, pressing machine pdf, metal lathe and milling machine, laser welding tool, etc. For more, contact us.

Send product request

Other supplier products

| AUTOMATION EQUIPMENT FOR HARDWARE SURFACE TREATMENT | The equipment uses two methods of duplex position vertical and horizontal for cylindrical polishing to meet the product brightness and smoothness; ... | |

| AUTOMOBILE BRAKE DISC MILLING MACHINE | AUTOMOBILE BRAKE DISC MILLING MACHINE The equipment is a CNC milling machine developed and produced for the milling processing of the forklift bra... | |

| VERTICAL MILLING MACHINE | This vertical milling machine chinais made with commercial quality, giving you the best value. The versatile design allows you to work with a varie... | |

| SINGLE RIB BRAKE SHOE ROLLER WELDER | The single-rib brakes and shoesseam welding machine adopts intermediate frequency welding technology. The intermediate frequency transformer has th... | |

| FOOD STEAMER STAINLESS STEEL BELT LASER WELDER | The equipment is mainly anindustrial laser welding machinedesigned for steamer and other products. According to the characteristics of the stainles... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |