Eplus3D Metal Additive Manufacturing

Machines & Materials For Your Metal 3D Printing Demands

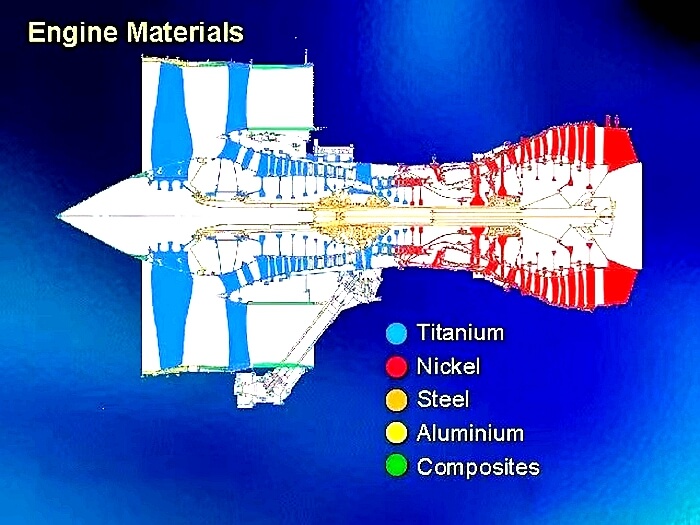

Eplus3D metal printers are a lab from entry-level models to multi-layer machines for additive production at industrial grades. We also provide advanced processes industrial metal 3D printing with the most various metal materials compatible, including aluminum alloys, titanium alloys, cobalt chrome, nickel-based alloys, stainless steel, tool steels, copper alloy, and other micro-grade metal powders.

Choose Eplus3D for slm 3d metal printer

Eplus3D is a trusted and reputable supplier of SLM metal 3D printers in China, specializing in providing high-quality and reliable metal 3D printing solutions to industries such as aerospace, automotive, medical, tooling etc.

Our metal additive manufacturing machineutilize advanced laser technology to selectively melt metal powders layer by layer, resulting in high-precision and high-quality 3D printed metal parts. Eplus3D offers a range of metal materials for their printers, including titanium alloys, stainless steel, cobalt-chrome, and more.

Eplus3D is committed to providing excellent customer service and support, and We offer comprehensive training and technical support to their customers. We also continuously innovate and improve our products to stay at the forefront of the industry.

What is SLM 3D Printing?

Selective Laser Melting (SLM) is a metal 3D printing process that uses a high-powered laser beam to melt and fuse together metallic powders layer by layer, ultimately creating a 3D object. It is one of the most commonly used metal 3D printing processes for creating high-strength, complex, and precise metal parts with excellent material properties.

The SLM metal 3D printing process begins with the creation of a 3D digital model of the desired part, which is then sliced into thin layers. A layer of metallic powder is spread onto a build platform, and the laser is directed onto the powder, selectively melting and fusing it together at specific points according to the digital model. The build platform then moves down, and the process is repeated for each layer until the object is fully formed.

SLM metal 3D printing offers several advantages over traditional manufacturing methods, including the ability to produce complex geometries with high precision and accuracy. It also offers design flexibility and reduced material waste, as only the required amount of metal powder is used in the process. Furthermore, SLM metal 3D printing can produce parts with improved mechanical properties, such as high strength, stiffness, and durability.

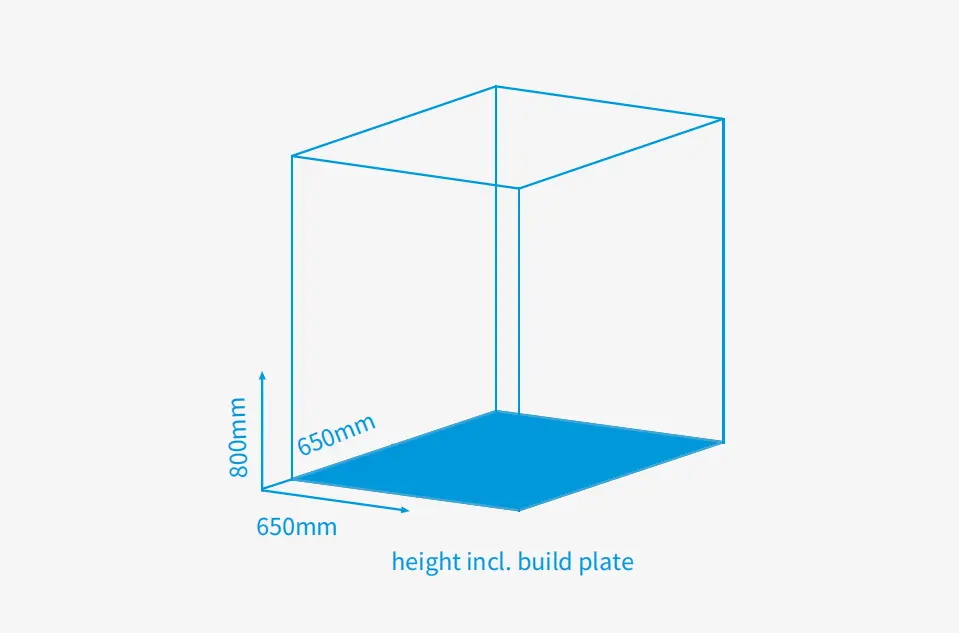

Despite its advantages, aluminum 3d printing machinealso has some limitations. It can be a slow and expensive process, and the quality of the final product can be affected by factors such as the quality of the metal powder, the power and accuracy of the laser, and the design of the object itself. Additionally, the size of the parts that can be produced is limited by the size of the build chamber.

Eplus3D, as a professional supplier of titanium 3d printing machine, provides different types of high-precision SLM 3D printing machinesand supporting printing materials. If you have any needs or you're interested in our SLM metal 3D printer for sale, please feel free to inquire Eplus3D for more details and the metal 3D printing machine price.

Metal Additive Manufacturing Processes

There are a number of different technologies used in the metal Additive Manufacturing systems available today.

Systems can be classified by the energy source or the way the material is being joined, for example using a binder, laser, heated nozzle, etc. Classification is also possible by the group of materials being processed, such as plastics, metals, or ceramics. The feedstock state, with the most common ones being solid (powder, wire, or sheet) or liquid, is also used to define the process.

What is Metal Additive Manufacturing?

Metal additive manufacturing integrates comprehensive technologies such as powder bed laser fusion, metal binder jetting and laser cladding. MPBF™ (Metal Powder Bed Fusion), as used by Eplus3D metal 3D printers, follows the principle of the proven PBF technology for almost 30 years and is now the standard in metal 3D printing for direct industrial production. The MPBF method is primarily applied for manufacturing in demanding industries such as aerospace, automotive, dental, healthcare, tooling and machinery. Those industries demand uniform part quality with high-performance properties like those achieved by conventional casting or forging processes.

We are the leading provider for high-end metal 3D printing. With our MPBF technology, we empower our customers from different industries to achieve the highly reliable and repeatable parts production.

For more information about 3d printing powder cost, please feel free to contact us!

EPLUS 3D, as an excellent industrial 3d printer manufacturers, offers a wide range of metal additive manufacturingfor you to choose from.

Send product request

Other supplier products

| EP-C5050 Wax/Sand SLS 3D Printer | EP-C5050 is able to use psbpowder to print investment molds with the building chamber size is 500x500x500mm. Together with traditional casting tech... | |

| Additive Manufacturing Material | Eplus3D solutions provide a wide range of high-quality powders and unique parameter sets to guarantee Eplus3D machines are able to meet customers' ... | |

| Eplus3D EP-M650 Metal 3D Metal Printing Machine | Using MPBF™ (Metal Powder Bed Fusion) technology, EP-M650 is using a large building envelope and 4/6/8 laser systems to ensure a high efficie... | |

| Eplus3D Metal Additive Manufacturing | Machines & Materials For Your Metal 3D Printing Demands Eplus3D metal printers are a lab from entry-level models to multi-layer machines for a... | |

| Inconel 718 - Mainstream 3D Printing Material for Additive Manufacturing | After World War II, the word "superalloy" came into being to describe a kind of high-performance alloys, which was specifically developed to extend... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |