Inconel 718 - Mainstream 3D Printing Material for Additive Manufacturing

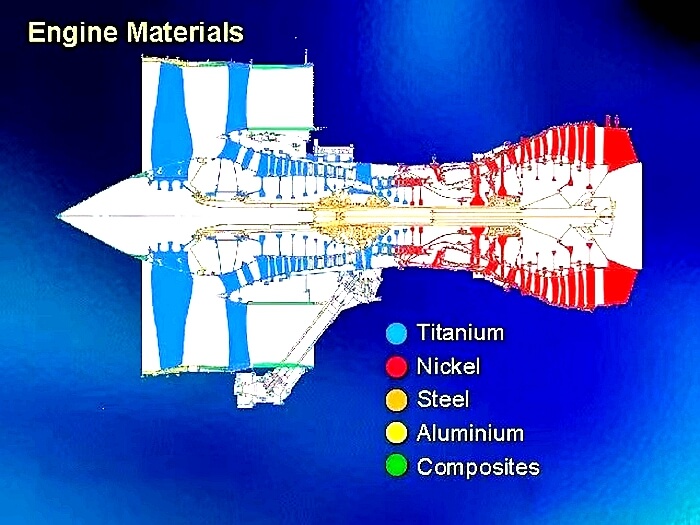

After World War II, the word "superalloy" came into being to describe a kind of high-performance alloys, which was specifically developed to extend the service life of aircraft parts exposed to extreme high temperature. Superalloy with nickel, iron, cobalt as the base, through the addition of alloy elements to achieve a variety of metal characteristics of super fusion, can work above 600℃ high temperature and a certain stress for long-term, become the mainstream material of aerospace, petrochemical, racing and other industries. Some studies show that the Inconel 718 accounts for more than one third of the nickel-based superalloy used in aerospace engines.

According to the Carnot cycle, running an engine at higher temperatures can improve energy efficiency, which in turn makes the engine more energy-efficient. The inconel 718 3d printinghas become a cornerstone of aerospace applications. It also has important applications in nuclear reactors (heat exchanger pipes), submarines (propeller blades, quick cut-off devices, auxiliary propulsion motors), chemicals (vessels, pumps, valves, pipes), power generation (industrial gas turbines), and the oil and gas industry (downhole pipes, wellhead hardware, torch arms).

Traditional manufacturing methods, such as machining, forging or welding, usually require heat treatment before the process begins, thus affecting the temperature corrosion and creep resistance of components. However, the mechanical properties of 3d printed In718 have not been sacrificed, and can even exceed those of cast or forged parts. In addition, Inconel 718 is difficult to machine because of its high cutting temperature and severe work hardening. For the complex geometries commonly required in aerospace applications, the Inconel 718 parts are often difficult and costly to manufacture.

3D-printed In718 Aeroengine Case by EP-M650

Low temperature performance of 3d printing Inconel alloy also has potential applications, pipe and shell, cryogenic suspension and support system, the structure of the impeller and pump, valve stem, cooling pipe, heat pipe, heat insulation design and heat exchanger are suitable for the application of high strength and high temperature alloy, its temperature range covers from the temperature of 273 ℃ to 760 ℃.

EP-M650 Metal Powder Bed Fusion Machine

Inconel 718 - Mainstream 3D Printing Material for Additive Manufacturing

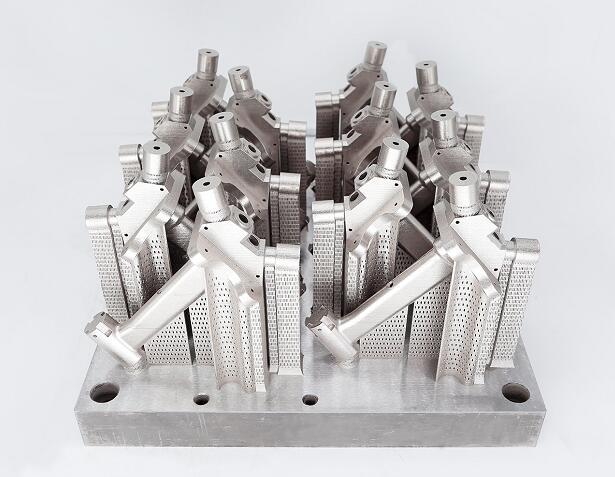

EP-M650 adopts MPBF (Metal Powder Bed Fusion) technology, with a 655 x 655 x 800 mm3 build envelope and four laser systems to ensure a high efficiency printing production. The precise positioning and innovative control technology hereby offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as Titanium alloy, Aluminum alloy, Nickel-based alloy, Stainless Steel, Chrome Cobalt alloy and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, automotive and defense industries. Welcome to contact us for more information.

EPLUS 3D, as an excellent 3d printing manufacturers, offers a wide range of 3d metal printing machinefor you to choose from.

Send product request

Other supplier products

| SLS 3D Printer | Eplus3D Polymer 3D SLSAluminium Printing Machines and Materials For Your Needs Eplus3D SLS polymer 3D printers are flexible machines for industri... | |

| EP-C5050 Wax/Sand SLS 3D Printer | EP-C5050 is able to use psbpowder to print investment molds with the building chamber size is 500x500x500mm. Together with traditional casting tech... | |

| Additive Manufacturing Metal Material | Eplus3D metal printers are available from entry-level models to muti-laser machines for additive production at industrial grades. We also provide a... | |

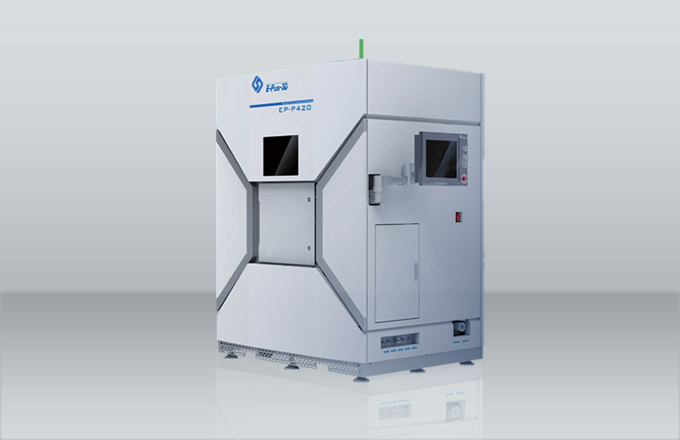

| EP-P420 SLS 3D Printer | Eplus3D EP-P420 adopts polymer powder bed fusion (PPBF™) technology, with max up to 420x420x465mm³ building chamber size, ensures you th... | |

| EP-M300 Metal 3D Printer | EP-M300 is a marvelous industrial metal 3d printerthat makes the production of reliable and high-quality large metallic parts viable on an industri... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |