STAINLESS STEEL WELDING MACHINE

Laser welding machine for stainless steeladopts laser continuous welding technology, high-precision servo motor feeding, high-speed clamping and other patented technologies, and combines multiple processes. Welding equipment has production advantages such as high efficiency, high quality and high energy saving. At the same time, the equipment is suitable for welding stainless steel strips in various industries, which is the best choice for production enterprises.

DIFFERENT TYPES OF STAINLESS STEEL WELDING MACHINE FROM XIHE

01

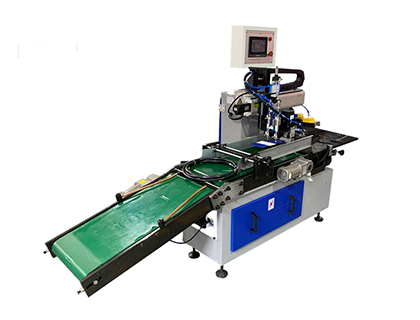

Stainless Steel Punching Machine

Equipment for automatic punching of stainless steel with steam holes for various types of glass pot lids.

02

Stainless Steel Belt Crimping Machine

Equipment for realizing automatic crimping of stainless steel belt in Kitchenware and other industries.

03

Stainless Steel Belt Stretching Machine

Automatic stretching equipment for rapid stretching of stainless steel rings of glass pot lids.

04

Stainless Steel Belt Chamfering Machine

Automated equipment for customized production of G-ring pressure angle for glass pot lids.

05

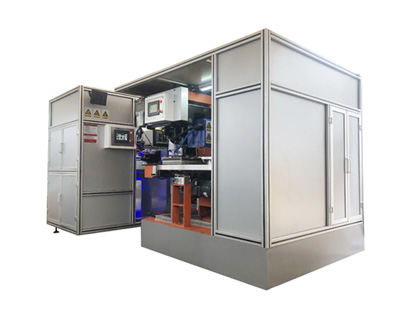

Stainless Steel Belt Laser Welder

Fully automatic multi-industry stainless steel belt laser cutting seamless welding equipment.

06

Stainless Steel Angle Pressing Machine

Automated equipment for customized production of G-ring pressure angle for glass pot lids.

Stainless Steel Punching Machine

Stainless Steel Belt Crimping Machine

Stainless Steel Belt Stretching Machine

Stainless Steel Belt Chamfering Machine

Stainless Steel Belt Laser Welder

Stainless Steel Angle Pressing Machine

HOW TO CHOOSE STAINLESS STEEL WELDING MACHINE?

Each industry has different quality standards, and the material of stainless steel is also different, so please tell us some of your relevant information, we will help you match the most suitable ss steel welding machinefor you, our welding machine can weld glass pot lids, nets Baskets, oil grids, sieves, paper drums, trash cans and other stainless steel materials, is your ideal welding equipment manufacturer. I hope we can move forward hand in hand and achieve a win-win situation.

3 COMMON METHODS FOR USING STAINLESS STEEL WELDING MACHINE

Laser continuous welding is the most advanced welding technology for stainless steel at present.

1

Preparations before starting the laser welding machine: Check whether the power supply and water circulation of the laser welding machine are normal; check whether the gas connection of the equipment in the machine is normal; check whether the surface of the machine is free of dust, spots, oil, etc.

2

Laser welding machine on/off

Start the automatic laser welder: Turn on the power supply, turn on the main power switch; turn on the water cooler, laser generator, etc. in sequence; open the argon valve, adjust the gas flow; input the current work parameters to be executed; Perform welding operations.

Laser welding machine shutdown: Exit the program, turn off the laser generator; shut down in order except.

3

Precautions for safe use of laser welding machine china: During operation, in case of emergency (water leakage, abnormal sound from the laser, etc.), press the emergency stop immediately and cut off the power quickly; the external circulating water switch of laser welding must be turned on before operation.

APPLICATIONS

STAINLESS STEEL WELDING MACHINE APPLICATIONS YOU MAY ALSO INTERESTED IN

Chemical Industry

Extensive use of seamless welding equipment for stainless steel strips in many industries, using continuous water-cooled laser welding technology, after welding, the surface of the product has no creases, no scratches, and is bright and beautiful.

Kitchenware Industry

It is suitable for the stretching process after the welding and crimping of stainless steel strips in the kitchen utensil industry, which saves labor costs, and perfectly cooperates with the previous process to realize automatic stretching production.

We can offer different kinds of stainless steel welder for saleand the stainless steel welding machine priceis reasonable, if you have needs, please contact us.

Send product request

Other supplier products

| AUTOMATION EQUIPMENT FOR GLASS INDUSTRY | The equipment is mainly customized and developed for the glass production and processing of glass pot lid manufacturers. The equipment uses laser c... | |

| AUTOMATIC PRODUCTION LINE OF STAINLESS STEEL BELT FOR POT COVER | The stainless steel belt automatic production line is an automatic welding and forming production line developed for the G-ring of the kitchen glas... | |

| MESH BASKET STAINLESS STEEL BELT AUTOMATIC PRODUCTION LINE | The equipment adopts advanced laser continuous welding technology, through the welding machine fixture feeding - cutting - welding, mechanical arm ... | |

| DOUBLE RIB BRAKE SHOE ANGLE WELDING MACHINE | It is suitable for the positioning and welding of the welding seam at the outer corner formed by the double rib arc plate and the rib plate of the ... | |

| DOUBLE ENDED POLISHING MACHINE | Double ended polishing machineusing Inovance PLC (programmable logic controller) control system;The polishing wheel is made of hemp wheel material,... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |