CNC EDM Wire Cut Machine For Sale

All supplier products

Among all cnc wire cut machine suppliers, we are the one who can not only offer high-quality cnc electric spark wire cutting machinebut outstanding service all the time. With a reasonable wire cut CNC machine price, we make sure to provide you with wire EDM machines of high precision.

What is CNC EDMWire Cut Machine?

CNC EDM Wire Cut Machine refers to a wire EDM machine that uses continuous moving fine metal wire as an electrode, on the workpiece pulse spark discharge to remove the metal, cutting and forming. Early CNC wire EDM machines used electric model-tracking to control the cutting path. Due to the low cutting speed, wire cut electric discharge machining is only used in the electronic industry processing at that time. With the continuous development of pulse power supply and digital control technology as well as the application of multiple wire electrical discharge machining technology, the cutting speed, and machining accuracy of the desktop EDM wire cutting machine for sale in DMNC have been greatly improved. And DMNC has various types of cnc wire cutting machinefor sale. If you take interest, please feel free to contact us to learn more about cnc edm wire cutmachine price

CNC Wire Cut Machine Process

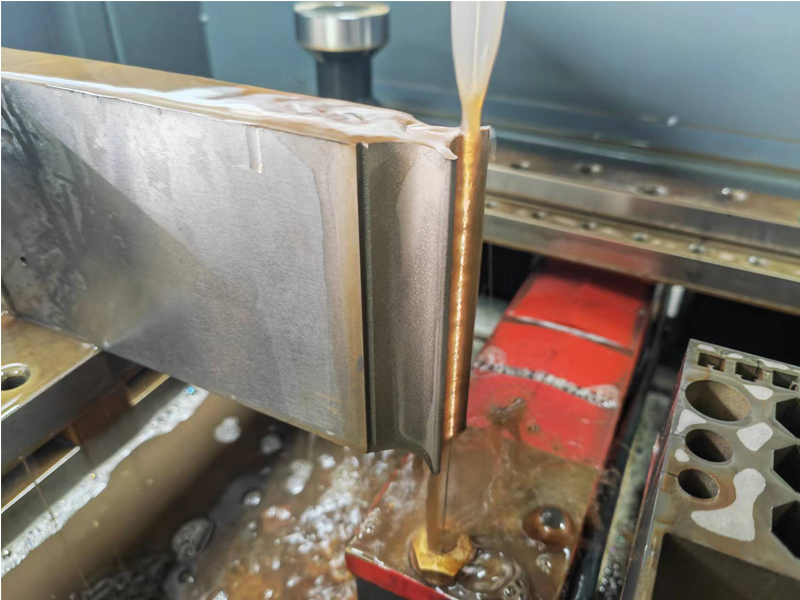

The workpiece is mounted on a desktop wire edmmachine workbench, which is usually driven by X - and Y-axis motors. The wire EDM machine control system outputs the corresponding information according to the pre-input working program so that the workbench moves accordingly, and the workpiece is close to the electrode wire. When the two close to the appropriate distance will produce spark discharge and corrosion of metal. After the metal is removed, the distance between the workpiece and the electrode wire is increased. According to the size of this distance and the pre-input program of the desktop wire edm machine, the control system constantly sends out the feed signal, so that the cnc edm wire cut machineprocess continues.

EDM standards for electric discharging machining, which is a kind of special machining technique, electrode and workpiece(conductive material) connect to positive and negative anodes of high frequency power respectively, with control of CNC system, when electrode approaches workpiece to a tiny distance, the gap between electrode and workpiece is broke through, spark with high temperature appears, and erode the workpiece. As there is no physical touching between electrode and workpiece, and temperature is so high, these advantages make EDM machining an ideal solution for machining complex shapes and super hard materials like hard alloy, titanium alloy. There are two typical applications of EDM technology cnc high speed wire cut edmand die sinking EDM.

Die sinking EDM is like a kind copy machining, it’s just like stamping on the workpiece, the complete machining requires an electrode, dielectric fluid and HF power. the shape of electrode is produced according to the products, for instance, it could be eyeglasses frame shape, keyboard shape, mobile shell shape,pen shape, coin shape, souvenir medal shape, bottle cap shape and so on. Along with forward movement of electrode, spark appears and erode the workpiece(conductive material), a cavity of same shape electrode is created on the workpiece. Die sinking machining is a kind of high precision machining, DMNC’s CNC EDM machines can make mirror surface finish with high accuracy. With advanced control system, DMNC’s CNC EDM can realize 5-axis simultaneous control for turbine machining.

Wire cut EDMalso requires electrode, dielectric fluid and HF power. The difference is electrode, wire EDM uses metal wire with small diameter, mainly brass wire or molybdenum wire for different types of wire EDM. The wire goes towards workpiece according to programmed path, when wire approaches workpiece to a tiny distance, breakthrough happens, spark with high temperature appears, when erodes the workpiece, and workpiece is split separately.

In short, wire EDM is more like cutting off and die sinking EDM is more like digging a hole/cavity with certain shape.

According to different characteristics of wire EDM and sinker EDM, wire EDM is mainly used for metal punching die, male and female die, cut off parts; Sinker EDM is mainly use for plastic injection molds, small ribs, extrusion di, die-casting mold and etc.

Send product request

Other supplier products

| Double Heads Large CNC EDM Machine | Double heads CNC EDM has two separated spindles and controllers, travel of table is much bigger than regular big EDM machines, each head can do mac... | |

| High Speed CNC Milling Machine G-600 | CNC wire cut EDM, which is a kind of spark erosion machine or electrical discharging machine, utilizes electrode wire (normally molybdenum wire or ... | |

| Double Heads Large CNC EDM Machine | Double heads CNC EDM has two separated spindles and controllers, travel of table is much bigger than regular big EDM machines, each head can do mac... | |

| Double Heads Large CNC EDM Machine | Twin-head large EDM CNC sparking machinehas two separated spindle heads and two separated controllers, also called double column CNC EDM machine, ... | |

| EDM Machine Parts | BIEM is one of the keyedm machine manufacturer, we provide cnc electronic discharge machinemachine, edm machine parts, spark edm machine, cnc edm d... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |