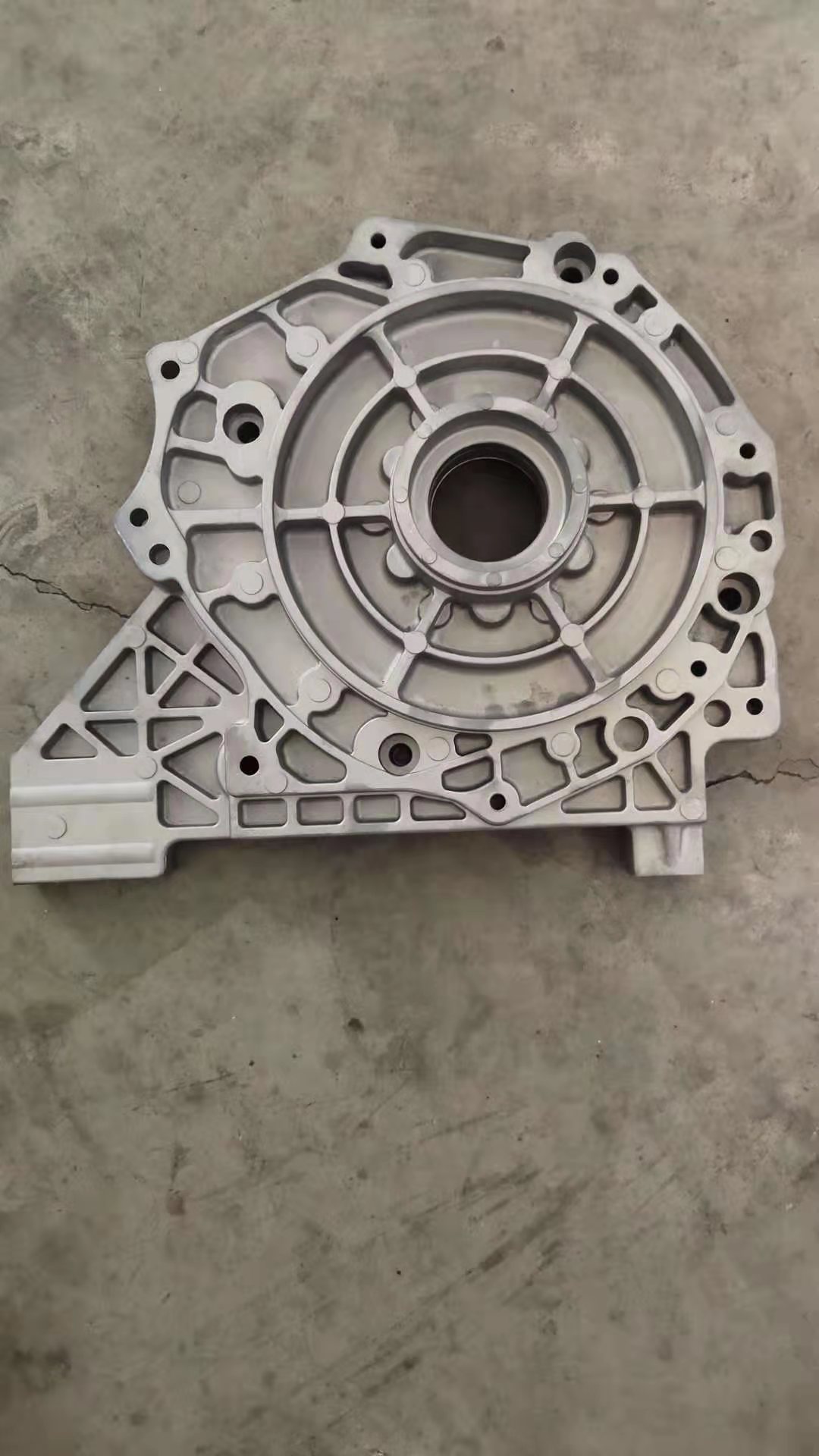

Aluminum Casting

Aluminum is a lightweight metal with silvery-white color. Because of its chemical features, aluminum never exists in the metallic form in nature. But aluminum compounds are abundant, and with the development of modern extraction technology, now aluminum becomes one of the most widely applicable non-ferrous metals. The casting process is one of the major methods applied to form the aluminum into the required product.

The basic method of aluminum gravity die castingmolding is relatively similar to iron casting, sand casting such as sodium silicate sand casting, and die casting. There're other techniques such as lost foam and lost investment casting methods. And these methods also are used by the foundry to apply to some specific demands, but only in fewer cases.

Rayforce aluminum die casting factoryuses state-of-the-art equipment to offer the aluminum casting product with great flexibility and competitive price for our clients. The production method by green sand and lost investment casting is able to make all size and complexity model products, with beautiful surface quality, and fast delivery from prototype to finished product.

Features of Manufacturing Aluminium Die Casting Products

High pressure and high speed filling low pressure aluminum castingtype are the two main characteristics of making aluminum die-casting products. It is a commonly used pressure injection ratio from thousands to tens of thousands of kPa, even up to 2 × 105 kPa. The filling speed is about 10 ~ 50m/s. Sometimes even up to 100m/s or more. The filling time of injection die casting is very short, generally in the range of 0.01~0.2s.

With strict inspection, as one of aluminum investment casting companies, Rayforce provides high-quality products for customers at a reasonable aluminium die casting price.

Advantages of Aluminum Casting Alloys

Aluminum casting alloys have some unique advantages compared with other castings like squeeze die casting, such as beautiful, lightweight, and corrosion resistance, which makes them widely favored by users, especially since they are lightweight automobiles. Aluminum casting alloys have been widely used in the automotive industry. The density of aluminum cast alloy is smaller than cast iron and cast steel, while the specific strength is higher.

Aluminum casting alloys have many advantages, which makes them become the development direction of the casting industry and one of the most popular casting products for customers purchasing. In the future, with the progress of aluminum casting alloy technology in aluminum sand casting foundry, it will show itself on a bigger stage.

As a reliable castings company, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Investment Casting | Direct investment casting, also called the lost-wax casting process, is actually an ancient metal investment casting technologywith a history of ov... | |

| Sodium Silicate Sand Casting | Sodium silicate sand castingis soluble in water in various amounts. A more common name for sodium silicate is water glass, which is used in iron or... | |

| Investment Casting | Investment casting, also called the lost-wax casting process, is actually an ancient metal casting technology with a history of over 6,000 years. I... | |

| Semi-Solid Die Casting | Based on the theory of stir cast invented by Mr. D.B. Spencer and M.C.Flemings, the semisolid die castingtechnic has been further developed and app... | |

| Lost Wax Investment Casting | Lost Wax Investment Casting The lost wax casting aluminumprocess can differ depending on the application and the requirement, but it generally con... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |