Compressors & Gears

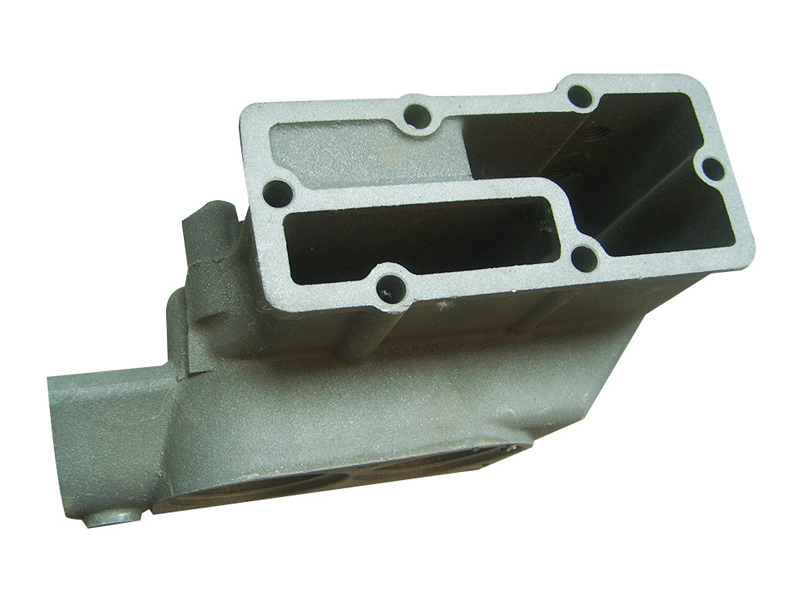

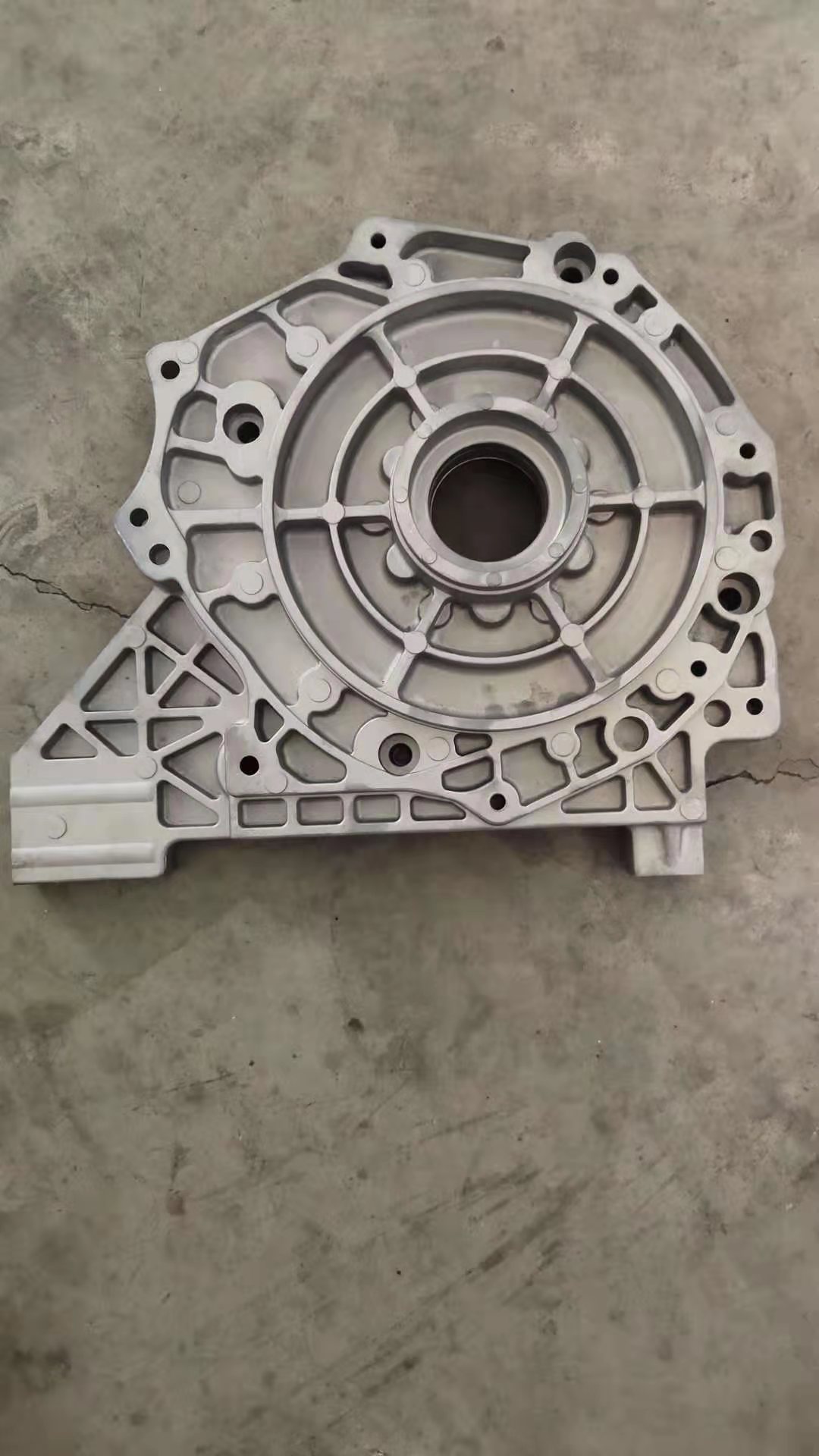

Rayforce's metal die casting gearscan be applied to Turbo blowers, air control components, piston compressors, casting gears, etc.

Application of Die Casting Gears in Air Compressors

With the continuous development of the automotive industry, the efficient high-precision die cast iron gearsproduction process including squeeze die casting is widely used in the production of automotive parts. Among them, the air conditioning compressor shell is a class of commonly used casting gears. This kind of shell product design has a compact structure and high requirements for sealing. The whole machine's annual leakage requirements are strict. Once a large refrigerant leakage will affect the cooling effect of automotive air conditioning, which will seriously lead to air conditioning not cooling. For the lower shell, airtight inspection requirements generally to the pressure of about 3MPa, holding pressure time of about 2min conditions shall not leak. To achieve these leak detection conditions, slight fluctuations in the quality of the casting, it is easy to cause bulk leakage, which will seriously affect the host plant production schedule on schedule. Overall, the application of die casting gears in air compressors is a reliable and cost-effective solution for producing high-quality gears that meet the demanding requirements of industrial applications.

Requirement of Die Casting Gears in Air Compressors

The lower casing is an important part of an automobile air conditioner compressors, which has high requirements for its performance. The influence of casting gears shape structure and mold scheme design makes the casting easy to produce casting defects, which leads to the leakage of the product becoming scrap after machine addition and seriously affects the subsequent assembly work beat and progress.

The analysis result of the die casting system composed of mold and die casting gears machine, after the improvement of die casting mold pouring system, the filling speed of the mold is reduced down, while the filling time is shortened significantly, no sticky mold occurs again at the gate. The casting gears are effectively shrunken. The spraying time is also reduced to the normal level. The passing rate of the product in actual production is increased from 70% to more than 97%, thus significantly reducing the product cost. Sometimes this process is related to silica sol casting. Besides, this has greatly reduced the product cost, prolonged the service life of the mold, enhanced the market competitiveness of the product, and brought good economic benefits to the enterprise.

If you are looking for a reliable cast metal manufacturer, please choose us, and we will be your best partner.

Send product request

Other supplier products

| Art & Home Sculptures | Rayforce's metal casting can be applied to Home accents, casting crafts, home sculpture, umbrella base, table and chair, patio bench, etc. Rayfo... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

| Die casting | Die Casting involves 3 key elements: the die casting machine, the mold, and the alloy materials, and the die casting could be described as the proc... | |

| Aluminum Casting | Aluminum is a lightweight metal with silvery-white color. Because of its chemical features, aluminum never exists in the metallic form in nature. B... | |

| Brass,Bronze,Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |