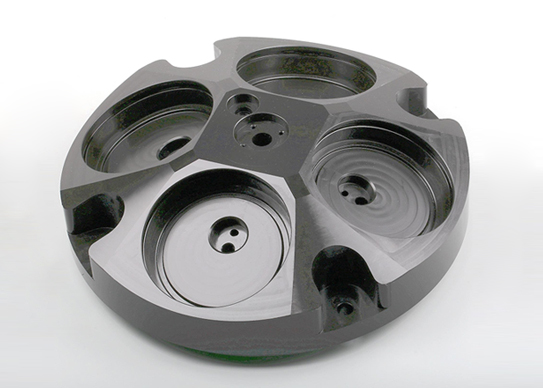

BLACKENING COATING

Put the metal parts into the solution of NaOH, NaNO2 and other potions. At a certain temperature, the parts will react chemically to produce a thin blue (black) oxide film. Blackening can be divided into normal temperature blackening and high temperature blackening. Generally, the surface oxide film of normal temperature blackening is relatively thin, and the effect of secondary blackening is better. The blackening surface treatmenttemperature at high temperature is about 135 ° to 155 ° and the blackening effect is also the best.

What Is Blackening For Metal?

Metal blackening is a common CNC surface finish treatment process. The purpose of blackening is to prevent rust on the metal surface. There are two kinds of metal blackening: alkaline heating blackening and normal temperature blackening. The problem of checking the antirust effect may occur due to process problems in normal temperature blackening.

How Do You Blacken Metal?

The process flow of metal blackening is as follows:

Degreasing: Boil the parts in degreasing solution for 20~30 minutes at 80~100 ℃.

Cold water cleaning: rinse with flowing clean water.

Pickling: wash with hydrochloric acid solution at room temperature for no more than 30 seconds.

Blackening (put the blackening liquid in a stainless-steel container and heat the bottom with an electric furnace)

Water washing: wash with flowing cold water or warm water for 30-60 seconds.

Boiling water cleaning: 2-5 minutes.

Saponification treatment: temperature 80~90°, time 2-3 minutes.

Immerse in oil: immerse in transformer oil or spindle oil at about 80° for 1-3 minutes, and then the finished product is cleaned.

As a professional cnc machining exporter, Richconn provides cnc machining services, blackening coating, precision cnc machining, etc. Want to know more, contact us.

Send product request

Other supplier products

| What Are The Characteristics Of CNC Machining? | What Are The Characteristics Of CNC Machine? Process concentration, automation, high flexibility, and strong capabilities are the characteristic... | |

| CHINA 4-AXIS & 5-AXIS CNC MACHINING | Richconn's fourth axis cnc& 5 axis CNC machiningservices are ideal for prototypes and low-volume production because we are responsive and we ha... | |

| POWDER COATING | POWDER COATING The atomized paint is sprayed on the metal surface and solidified after high-temperature baking to form the effects of anti-corrosi... | |

| CNC PLASTIC MACHINING | The characteristics of plastic cnc machining chinamaterial are defined by the melting point temperature (150 ° to 450 °) and the use enviro... | |

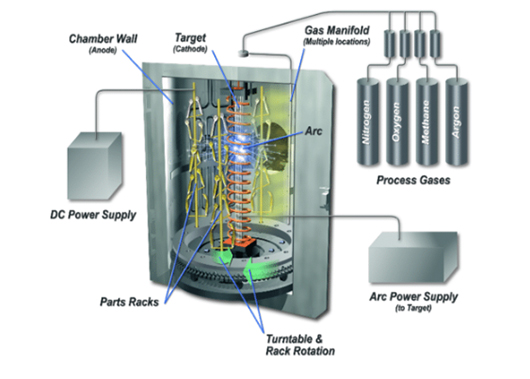

| PVD COATING | Physical vapour deposition, just PVD coating, as we usually call it, refers to vacuum ion plating and vacuum sputter plating; Generally speaking, n... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |