Common Quality Problems of Induction Quenching Machine and Ways to Improve Its Working

Performance

Ⅰ. Quality problems that often occur in high frequency hardening

The application of induction heating equipment in the quenching process is becoming more and more extensive. With the continuous improvement of this process, we generally encounter the following problems:

Ⅱ. Ways to improve the working performance of super audio frequency or high frequency induction heating power supply

In the process of actually applying super frequency or high frequency induction heating to induction quenchingmachine of machine-heated workpieces. In order to ensure the required performance and technical requirements, in addition to preventing the above defects, it is important to consider the state and technology of the parts before and after heat treatment. request etc.

According to the characteristics of the induction heating equipment, the structure of the inductor, the working conditions of the parts, etc., combined with the following precautions, the process flow and process parameters are correctly designed to produce qualified products.

- quenching machineof parts heated with induction heating equipment, the depth and distribution of the hardened layer should be reasonably determined, which affects the stress distribution of the parts and the fatigue strength of the surface.

- induction heating machineshould protect the threaded holes, pin holes and oil holes on the parts, such as blocking with copper material, to prevent the parts from overheating and quenching and cracking there.

If you are looking for a reliable induction heating manufacturer, don't hesitate to contact us!

Send product request

Other supplier products

| Wooden Carbide Brazing | JKZcan provide you a complete induction heating machine chinaexperience service. Our service staff will give customers a full response immediately,... | |

| Medium Frequency Induction Heating Machine | If you need hot forging for large workpieces, smelting for ferrous or non-ferrous metals or deep heat treatment, the MFS series of intermediate fre... | |

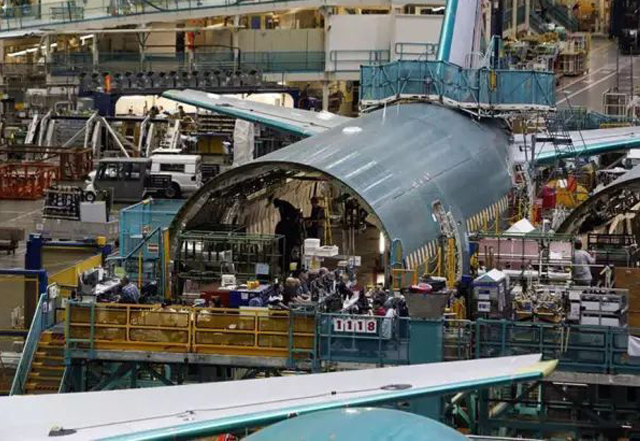

| Induction Heating Machines In Aviation And Aerospace | Aviation and aerospace are manifestations of high standard industrial capabilities. Induction heating is widely used in the aerospace industry, and... | |

| Ultrasonic Frequency Induction Heating Machine | SWS series ultrasonic heating machinehas a very wide application field. It can be used in automobile and motorcycle parts production, metal hot for... | |

| Carbide Production | Induction Heating Machines In Carbide Heating with InductionProduction Hard alloy carbide is an important raw material for cutter heads. At presen... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |