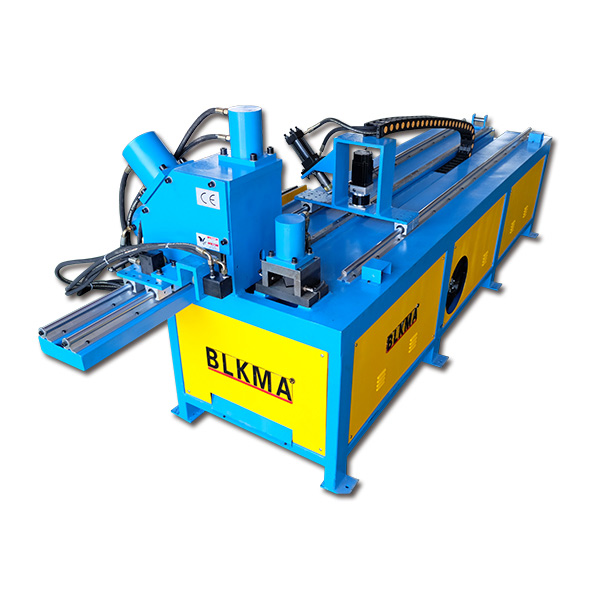

TDF Clip Cutting Machine

TDF Clip Cutting Machine Performance Features:

|

Model |

Max thickness(mm) |

Power(kW) |

Weight(kg) |

Dimensions(mm) L*W*H |

|

C-15 |

200 |

620*500*1350 |

The hydraulic TDF clip cutting machine is used to cut TDF flange. Maximum sheet thickness is 1.5mm. It's suitable for processing HAVC duct on site due to easy operation and small size, this machine is specially used for the production of connecting air ducts. The biggest feature of this corner code assembly machine is the convenience of movement. It can be moved anywhere and start to work. Very convenient and practical, cost-effective also very high. Can solve a lot of trouble for the customer. And the power of this TDF clip cutting machine is 2.2kw, the weight only 200kg, it's very labor-saving to moves, this TDF clip cutting machine is designed by us for a long time, and it will be more accurate in the production process, stability has also been greatly improved. And it's much safer and easier to operate. The BLKMA brand is the best choice. The TDF clip cutting machine work with CNC auto duct production line machine, it can connect the rectangular duct, and can make the duct tightly connected together, will never fall off. BLKMA company can provide a complete solution for rectangular air duct making machines and we can also customize machines in accordance with customers needs, also it's much safer and easier to operate. Due to all the parts of our machines are imported, this is more conducive to the use of the machine and can increase the service life of the machine. The products produced by our machine are not only beautiful but also firm, can satisfy all the needs of the guest, our factory is located in the center of China’s machine tool industry, Ma’anShan Bowang District Dongcheng Industrial Park, it is very convenient only takes 20mins to Nanjing Lukou International airport and connected with Jiangsu, Zhejiang, and Shanghai. We are one of the leading clip machine manufacturersince 1994.

TDF Clip Cutting Machine Basic Configuration:

One motor

One control electric system

One hydraulic system

One cylinder

One punch mold

One foot switch

Four pulley.

BLKMA, as an excellent spiral duct machine manufacturer, offers a wide range of heavy industrial machineryfor you to choose from.

Send product request

Other supplier products

| Auto Duct Production Line 3 2019 | Duct production line 3 can drive blanking for duct. Meantime, it’s very suitable for diversified production like TDF/angle steel/inserted fla... | |

| Electric Lock Seaming Machine | Electric Lock Seaming Machine Performance Feature: Electric seam locker machinecan lock square HVAC air duct. The sheet thickness range is 0.3-1.2... | |

| Spiral Duct Forming Machine | Spiral Duct Forming Machine Performance Features: Model Diameter range Thickness range(mm) Width(mm) Feeding speed(m/m... | |

| Hand Folding Machine | This machine is able to bend the flange sheet metal to get three folds, and it's also considered as a general crimping machine. Hand Folding Mac... | |

| CNC Angle Steel Production Line | CNC Angle Steel Production Line CNC Angle Steel Production Line Performance Features: Fully automatic angle steel flange production line, or CNCa... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |