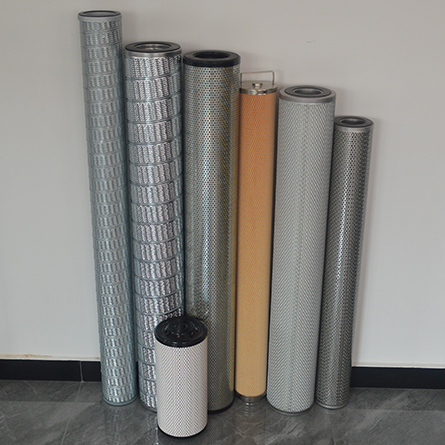

FILTER ELEMENTS & FILTER CARTRIDGE FOR SALE

The filter elementcan purify the polluted media, and achieve the cleanliness required by our production and life, with a certain degree of cleanliness. Filters are widely used, ranging from industrial products such as iron and steel smelting, electric power production, and ocean purification, etc. to domestic drinking water treatment, domestic garbage utilization, automobile burning filtration, bicycle lubricating oil filtration, etc. Therefore, cartridge filter elements are used in clean technologies in our lives. The hydraulic system is divided into an oil suction filter, pipeline filter, and oil return filter.

Filter Element & Filter Cartridge Types

Filter cartridges are essential components in various industrial and commercial applications that require the removal of impurities and contaminants from liquids and gases. These OEM filter cartridges come in different shapes, sizes, and materials, and are designed to filter out particles of different sizes and types. There are several filter cartridges types available provided by our filter element manufacturer, such as coalescing filter element, separator element, pre-filter cartridge, and hydraulic filter element and so on, each designed for specific applications and environments. Each type has unique features and benefits, and choosing the right one for a specific application depends on factors such as the type of fluid or gas being filtered, the flow rate and pressure, and the level of filtration required.

Coalescing Filter Element

Equivalent of (PECO) Coalescing Filter Cartridge

Equivalent of (FACET) Coalescing Filter Cartridge

Equivalent of (FAUDI) Coalescing Filter Cartridge

Equivalent of (Parker) Coalescing Filter Cartridge

Equivalent of (Velcon) Coalescing Filter Cartridge

Coalescing Filter Element

Separator Element

Equivalent of (PECO) Separator Filter Cartridge

Equivalent of (FACET) Separator Filter Cartridge

Equivalent of (Parker) Separator Filter Cartridge

Equivalent of (Velcon) Separator Filter Cartridge

Equivalent of (PALL) Separator Filter Cartridge

Separator Element

Pre Filter Cartridge

Equivalent of (PECO) Pre Filter Cartridge

Equivalent of (FACET) Pre Filter Cartridge

Equivalent of (FAUDI) Pre Filter Cartridge

Equivalent of (Parker) Pre Filter Cartridge

Equivalent of (Velcon) Pre Filter Cartridge

Pre Filter Cartridge

Hydraulic Filter Element

Equivalent of (Parker) Hydraulic Filter Element

Equivalent of (HYDAC) Hydraulic Filter Element

Equivalent of (INTERNORMEN) Hydraulic Filter Element

Equivalent of (PALL) Hydraulic Filter Element

Equivalent of (MAHLE) Hydraulic Filter Element

Hydraulic Filter Element

Filter Element Characteristics

Precision filter element permeability

High efficiency of precision filter element

Precision filter element airtightness

Corrosion resistance of precision filter element

Filter Element Characteristics

The filter element is made of American fiber filter material with strong hydrophobicity and oleophobicity, and the framework with good permeability and high strength is adopted to reduce the resistance caused by passing.

The filter core adopts a German fine-perforated sponge, which can effectively prevent oil and water from being carried away by high-speed airflow so that the small oil droplets passing by gather at the lower end of the filter core sponge and are discharged to the bottom of the filter container.

A reliable sealing ring is adopted at the junction of the filter element and the filter shell to ensure that the air flow is not short-circuited and prevent impurities from directly entering the downstream without passing through the filtration elements.

Anti-corrosion reinforced nylon end cover and anti-corrosion filter core framework are adopted for filter core, which can be used in severe working conditions.

Filter Cartridge Installation

Before Installation:

During Installation:

After Installation:

Filter Element Typical Applications

Filter cartridges have various applications across different industries.

Electronic industry: pre-filtration of the reverse osmosis water system and pre-filtration of the deionized water system, remove impurities from chemicals used in the production of electronic components, such as semiconductors and printed circuit boards.

Food industry: filtration of beverages, beer, juices, wine, cooking oil, mineral water, etc., to remove particles, bacteria, and other contaminants from liquids and gases used in food processing and packaging.

Chemical industry: filtration of organic solvents,acids, inks, etc., to remove impurities and contaminants from chemicals used in various processes, such as refining and purification.

Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, compressed air, and gas filtration, to remove contaminants from liquids and gases used in drug manufacturing and packaging.

Others: electroplating solution, metal cutting fluid, photosensitive resist and filtration of magnetic media, automotive manufacturing, oil and gas refining, wastewater treatment, and air pollution control,etc.

The Basic Components of Filter Cartridge

Understanding the basic components and their roles within the filter element is crucial for comprehending the filtration process and ensureing optimal performance.

The filter media is the heart of the filter cartridge, responsible for trapping and retaining contaminants. It is typically made of a porous material, such as paper, fabric, mesh, or synthetic fibers. The filter media's primary function is to provide a barrier that allows the fluid or air to pass through while capturing particles, debris, or unwanted substances.

The core or support structure of a filter cartridge provides stability and strength to the filter media. It also assists in maintaining a consistent flow pattern and prevents channeling or bypassing of contaminants.

The end caps are located at the top and bottom of the filter cartridge, securing the filter media and core in place. Their role is to ensure proper alignment, prevent leakage, and facilitate easy installation and removal of the filter cartridge.

Gaskets or O-rings are sealing components placed between the filter cartridge and the filter housing. They create a tight and secure seal, preventing fluid or air from bypassing the filter media.

We can offer sorts of filter cartridge for sale, and the filter cartridge priceis reasonable, if you have needs, please contact us.

As a filter element company, we can offer sorts of related products for sale, if you have needs, please leave us a message.

Send product request

Other supplier products

| EQUIVALENT OF (PECO) COALESCING FILTER CARTRIDGE | Coalescence material, which guarantees the technical performance and quality of the filter element, is used to create the equivalent of the (PECO) ... | |

| PRE FILTER CARTRIDGE | The pre-filtration filter element includes a PP cotton filter element, folding filter element, wire-wound filter element, large flow filter element... | |

| HYDRAULIC FILTER ELEMENT | The filter element can be used for filtering hydraulic oil, water glycol, diesel oil, processing fluid, lubricating oil, coolant, gasoline, process... | |

| Coalescing Filter Element Applied in Petroleum Field | Coalescing Filter Element Applied in Petroleum Field The oil filter element helps to improve the purity of petroleum refining. The oil filter... | |

| SEPARATOR ELEMENT | The separator elementproduced and designed by Pyle Company is the second filter element of the filter separator, which can separate water droplets ... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |