GMC-SERIES GANTRY MACHINING CENTER

GMC series gantry mill for saleis the latest precision gantry boring and milling machining center jointly developed by Germany and DEED. The machine tool of gantry type cnc machining centercan complete milling, boring, drilling, rigid tapping, and three-axis linkage surface processing, and can add right angle milling head according to customer requirements to realize five side processing at one time, which can effectively improve processing accuracy and processing efficiency. Contact our cnc machining center factoryfor more information!

GMC-SERIES CNC GANTRY MILLING MACHINESPECIFICATION

CNC gantry milling machine CNC gantry milling machine

|

CNC gantry milling machine model |

GMC2016L |

GMC2516L |

GMC3016L |

GMC3516L |

GMC4016L |

|

|

Door width |

mm |

1600 |

1600 |

1600 |

1600 |

1600 |

|

X-axis |

mm |

2000 |

2500 |

3000 |

3500 |

4000 |

|

Y-axis Travel |

mm |

1600 |

1600 |

1600 |

1600 |

1600 |

|

Z-axis |

mm |

850 |

850 |

850 |

850 |

850 |

|

From spindle nose to worktable face |

mm |

200-1050 |

200-1050 |

200-1050 |

200-1050 |

200-1050 |

|

Table width |

mm |

1250 |

1250 |

1250 |

1250 |

1250 |

|

T-slot |

mm |

22 |

22 |

22 |

22 |

22 |

|

bearing |

t |

5 |

6 |

8 |

9 |

10 |

|

Spindle type |

r/min |

8000 |

8000 |

8000 |

8000 |

8000 |

|

Spindle form |

BT50 |

BT50 |

BT50 |

BT50 |

BT50 |

|

|

Main motor power |

Kw |

22/26 |

22/26 |

22/26 |

22/26 |

22/26 |

|

Spindle Torque |

560/660 |

560/660 |

560/660 |

560/660 |

560/660 |

|

|

Spindle box section |

mm |

400 |

400 |

400 |

400 |

400 |

|

Spindle taper hole specification |

BT50(HSK63 |

BT50(HSK63 |

BT50(HSK63 |

BT50(HSK63 |

BT50(HSK63 |

|

|

X-axis Rapid Traverse |

m/min |

16 |

16 |

16 |

16 |

16 |

|

Y-axis Rapid Traverse |

m/min |

16 |

16 |

16 |

16 |

16 |

|

Z-axis Rapid Traverse |

m/min |

16 |

16 |

16 |

16 |

16 |

|

Cutting Speed |

m/min |

12 |

12 |

12 |

12 |

12 |

|

Positioning Accuracy |

mm |

|||||

|

X (half-closed loop) |

||||||

|

Positioning Accuracy |

mm |

|||||

|

Y(half-closed loop) |

||||||

|

Positioning Accuracy |

mm |

|||||

|

Z(half-closed loop) |

||||||

|

Repeatability Accuracy |

mm |

|||||

|

X(half-closed loop) |

||||||

|

Repeatability Accuracy |

mm |

|||||

|

Y(half-closed loop) |

||||||

|

Repeatability Accuracy |

mm |

|||||

|

Z(half-closed loop) |

||||||

|

Power capacity |

Kva |

60 |

60 |

60 |

60 |

60 |

|

Air source pressure |

Mpa |

|||||

|

Machine size |

mm |

5100 |

5100 |

5100 |

5100 |

5100 |

|

height |

||||||

|

Floor area (about) |

mm×mm |

7520×4955 |

7850×4955 |

9000×4955 |

10250×4955 |

11250×4955 |

|

Machine weight |

T |

24 |

26 |

35 |

||

|

controller |

FANUC/SIEMENS |

FANUC/SIEMENS |

FANUC/SIEMENS |

FANUC/SIEMENS |

FANUC/SIEMENS |

Inquiry GMC16 gantry millfor sale at competitive bulk prices.

CNC GANTRY MILLING MACHINE FEATURES

Large work area: A CNC gantry milling machine typically has a large work area that can accommodate large workpieces.

High precision: The machine is designed to provide high precision and accuracy in machining operations.

High rigidity: The machine frame is made of high-quality materials to provide high rigidity and stability during machining.

Versatility: The machine can be used for a variety of machining operations, including milling, drilling, and cutting.

Automated operation: The machine is equipped with a computer control system that allows for automated operation, increasing efficiency and reducing operator errors.

Multiple spindle options: Many CNC gantry milling machines come with multiple spindle options, including vertical, horizontal, and multi-axis spindles.

Customizable: The machine can be customized to meet specific machining requirements, such as adding additional axes or tool changers.

Power and speed: The machine is equipped with powerful motors that provide high speed and torque for machining hard materials.

Robust construction: CNC gantry milling machines are built to withstand heavy-duty machining operations, with sturdy construction that ensures longevity.

Easy maintenance: The machine is designed for easy maintenance and can be easily serviced by technicians.

CNC GANTRY MILLING MACHINE APPLICATION

CNC gantry milling machines are used in a variety of industries for a wide range of applications. Here are some examples:

Aerospace: CNC gantry milling machines are used to machine large, complex aerospace components such as wing spars, engine mounts, and fuselage frames.

Automotive: The machine is used to machine large automotive components, such as cylinder heads, engine blocks, and transmission cases.

Defense: Defense contractors use CNC gantry milling machines to produce components for military vehicles, aircraft, and weapons systems.

Energy: CNC gantry milling machines are used in the energy sector to manufacturing components for turbines, generators, and other equipment.

Medical: The machine is used to produce medical implants, orthopedic devices, and other medical equipment.

Mold and toolmaking: CNC gantry milling machines are used to manufacture molds and tooling for various industries, including automotive, aerospace, and consumer products.

Prototyping: The machine is used to create prototypes of new products and designs quickly and accurately.

Robotics: As one kind of cnc industrial machine, CNC gantry milling machines are used to produce components for industrial robots, such as gears, drive shafts, and other precision parts.

Shipbuilding: The machine is used to manufacture large ship components such as propellers, rudders, and ship frames.

Architecture: The machine is used to create complex architectural designs, including sculptures and large-scale public artwork.

Send product request

Other supplier products

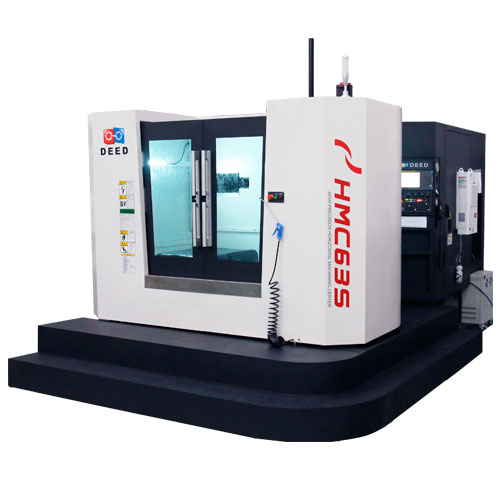

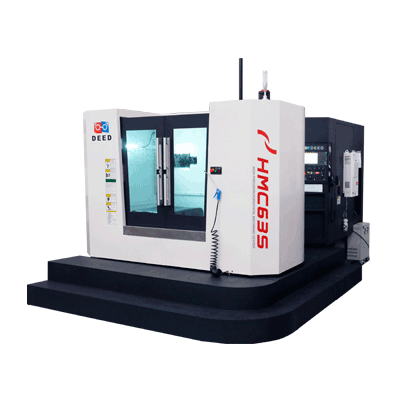

| HMC DOUBLE-PALLET HORIZONTAL MACHINING CENTER | This high-precision horizontal machining centre in cncwas designed and produced by our company on the basis of introducing and absorbing advanced t... | |

| 5-axis Machining Center | High-performance and high-precision machining center The bed and the column are cast in one piece of mineral materia The headstock adopts a... | |

| HBP SERIES PLANER TYPE MILLILING AND BORING MACHINE | The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut pre... | |

| Horizontal Machining Center | Suitable for various heavy cutting and high precision machining fields TYPES OF HORIZONTAL MACHINING CENTER FOR SALE The new horizontal machini... | |

| UNIVERSAL HORIZONTAL LATHE | The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas d... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |