Industrial Rotary Dryer Machine

CIC have accumulated decades of experience in the production of industrial sludge dryermachine, through continuous improvement, research and development, CIC sludge dryer manufacturersare looking for breakthroughs according to the site and operation conditions to make our dryer have the following advantages:

High degree of mechanization and productivity;

Low energy consumption, with low resistance generated when the fluid goes through the shell;

Strong adaptability for the various kinds of materials;

Stable and convenient heavy equipment and machinery operation, low costs, and great drying uniformity.

Introduction of sludge drying machine

Rotary dryer is a kind of highly efficient, stable and reliable heating drying equipment, and its performance is better than tube bundle rotary dryer, blade rotary dryer. Drying machine adopts "center-adjusting roller device", making the cooperation of roller and rolling ring always show linear contact which greatly reduces the wear and power consumption. This machinery is applied in the materials like coal slurry, mud, felted gypsum, high-moisture swell soil, electroplate mud and so on.

Principle of sewage sludge drying

The moist material enters the dryer from one end. With the stirring of the uniformly distributed lifting blade inside the shell, the material disperses equably inside the dryer. In this way, the material is fully exposed to the flowing hot air, and the drying process is quickened. During the drying process, the material is moved manageably to the other end of the dryer under the effect of both the gradient and the hot air. Thus the finished product is produced. The rotary dryer is mainly applied in the drying of the material, which requires low-temperature drying and mass continuous drying, for example, the drying of large particles and large specific gravity, such as the ore, coal, metal power, blast-furnace slag, phosphate fertilizer, thiamine, and so on, in the industries of chemical, rotary dryer for minerals, metallurgy and etc and the drying of powdery and granular material of special requirements, such as the HP foaming agent, vinasse slag, light calcium carbonate, activated clay, magnetic powder, graphite, herb residue, etc.

Technical Parameter of Rotary Dryer

|

Specification(m) |

Volume(m³) |

Capacity(t/h) |

Installation Inclination(%) |

|

Main Motor(kw) |

Total Weight(t) |

|

Φ1.2×8.0 |

3-5 |

700-800 |

9 |

|||

|

Φ1.2×10 |

3-5 |

700-800 |

11 |

|||

|

Φ1.5×12 |

3-5 |

700-800 |

15 |

|||

|

Φ1.5×14 |

3-5 |

700-800 |

15 |

|||

|

Φ1.5×15 |

3-5 |

700-800 |

15 |

|||

|

Φ1.8×12 |

3-5 |

700-800 |

||||

|

Φ1.8×14 |

3-5 |

700-800 |

23 |

|||

|

Φ2.2×12 |

3-5 |

700-800 |

22 |

|||

|

Φ2.2×14 |

3-5 |

700-800 |

22 |

36 |

||

|

Φ2.2×16 |

3-5 |

700-800 |

22 |

38 |

||

|

Φ2.4×14 |

3-5 |

700-800 |

37 |

45 |

||

|

Φ2.4×18 |

3-5 |

700-800 |

37 |

49 |

||

|

Φ2.4×20 |

3-5 |

700-800 |

45 |

54 |

||

|

Φ2.4×22 |

3-5 |

700-800 |

45 |

58 |

||

|

Φ2.6×24 |

3-5 |

700-800 |

55 |

73 |

||

|

Φ3.0×20 |

3-5 |

700-800 |

75 |

85 |

||

|

Φ3.0×25 |

3-5 |

700-800 |

75 |

95 |

||

|

Φ3.2×25 |

201 |

3-5 |

700-800 |

90 |

110 |

|

|

Φ3.6×28 |

285 |

3-5 |

700-800 |

160 |

135 |

Maintenance of Drum Dryer

Case of Rotary Dryer

Rotary Dryer for Indonesian customer

Speicification : Φ2.336×14m

Industrial Rotary Dryer Machine Application

Fertilizer & Granulation

Metallurgy

For more informationabout sludge dryer systemand industrial heavy machinery, please feel free to contact us!

There are many heavy equipment dealers, but we are one of the best choices for you.

Send product request

Other supplier products

| Furnace Tap Hole Machine | The manipulator is applied to the opening and plugging of the slag port in a copper smelting furnace. According to the copper smelting furnace slag... | |

| CIC Mining And Cement Equipment | CIC's heavy equipment and machinery include not only market-leading standardized products, but also customized products and related services accord... | |

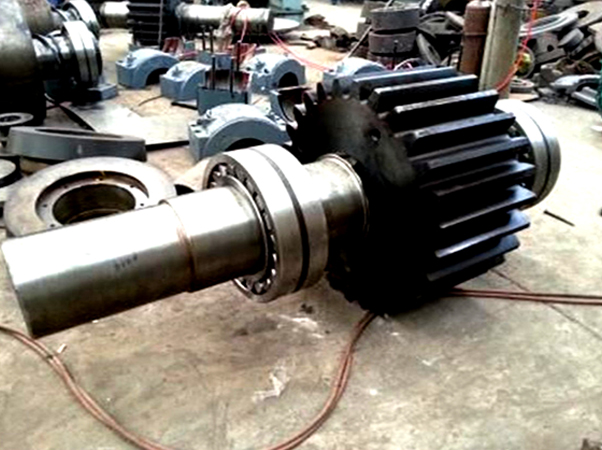

| Pinion Shaft | Pinion Shaft CIC is a more than 50 years pinion gear shaftmanufacturer and reputed supplier of forged pinion and pinion shaft widely used in vario... | |

| Horizontal Centrifuge | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Cement Rotary Kiln | Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processing rotating kiln equi... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |