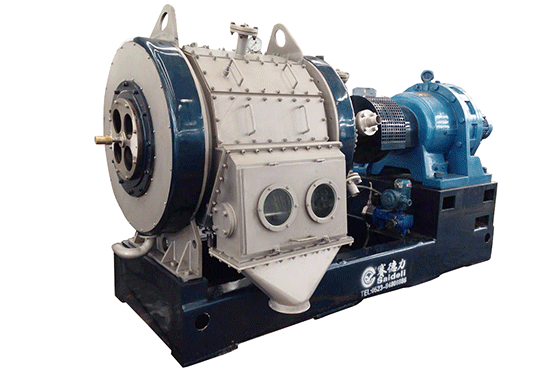

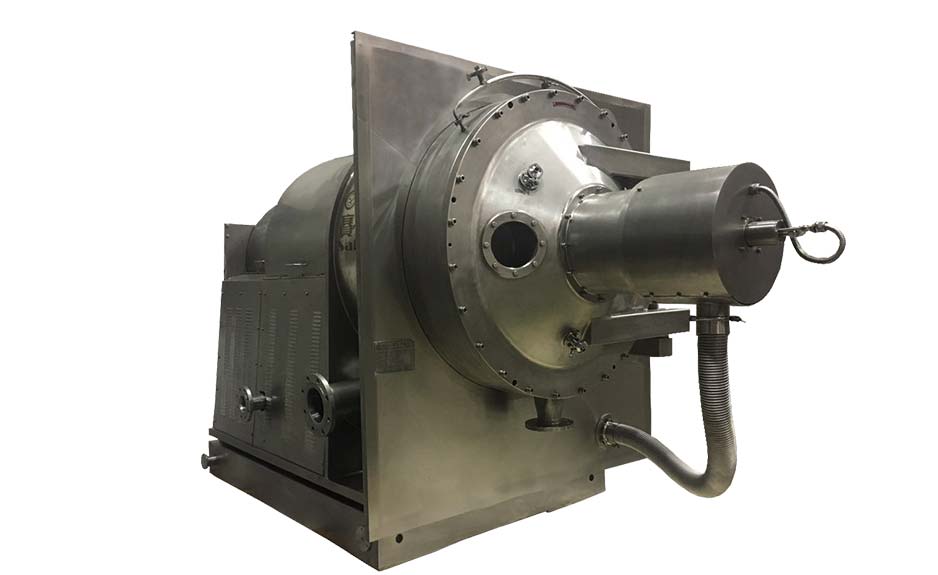

LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE

LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE

L(P)LGZ vertical basket centrifuges are suitable for solid-liquid separation of fibroid products as well as suspension which contains fine grains and medium-size grains solid. For example chemical industry products such as gypsum, ammonium sulfide, bluestone, potassium chloride, borax, dyestuff, resin, pesticide, food additive, starch, sugar, flavoring, antibiotic, vitamin and other industries such as mining and environmental protection, etc.

SPECIFICATION OF LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE

|

Item/Model |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

L(P)LGZ |

|

800 |

1000 |

1250 |

1350 |

1400 |

1600 |

1680 |

1800 |

|

|

Drum diameter (mm) |

800 |

1000 |

1250 |

1350 |

1400 |

1600 |

1680 |

1800 |

|

Drum Height (mm) |

400 |

500 |

500/630 |

630 |

700 |

800/720 |

740 |

800 |

|

Drum volume (L) |

80 |

165 |

310/400 |

445 |

560 |

800/720 |

900 |

1000 |

|

Loading capacity (Kg) |

100 |

210 |

400/520 |

534 |

672 |

1000/870 |

1125 |

1200 |

|

1500 |

1200 |

1000/1200 |

1200 |

1150 |

850 |

850 |

800 |

|

|

1007 |

805 |

698/1006 |

1086 |

1033 |

646 |

646 |

645 |

|

|

Motor power (KW) |

15 |

30 |

30 |

37 |

37 |

55 |

||

|

Size including shock absorber (mm) |

1700 |

2100 |

2300 |

2600 |

2600 |

3000 |

3000 |

3230 |

|

×1400 |

×1600 |

×1800 |

×2000 |

×2000 |

×2400 |

×2400 |

×2630 |

|

|

×2064 |

×2200 |

×2500 |

×2900 |

×3200 |

×3510 |

×3100 |

×3850 |

|

|

Weight (Kg) |

2100 |

3800 |

5600 |

6000 |

6500 |

12000 |

12500 |

16200 |

LLGZ Working principle

During the process of discharging, the scraper acts, under the impact of it most products are discharged through the blanking hole at the bottom of drum to the outside. The remnant product layer will be removed because of oscillation effect by the influence of automatic shaking-bag mechanism inside the drum.

Highlights of LLGZ Pull Bag Scraper Bottom Discharge Centrifuge

Automatic frequency speed control.

The vertical basket centrifugehas all advantages of common scraper centrifuge.

Full-automatic operation for shaking bag falling off and reset.

The filter bag can be moved up and down inside the drum to produce oscillation effect and remove the remnant filter cake thoroughly.

Big clamshell or whole shell reversible type are achievable according to users' demands.

The automatic residual cakes removing device is optional(have owned the national patent).

If you want to know more about basket centrifuge working principle, please visit our website.

As a reliable industrial centrifuge machine supplier, we can offer sorts of centrifuge machine industrialfor sale, if you are interested, please contact us.

Send product request

Other supplier products

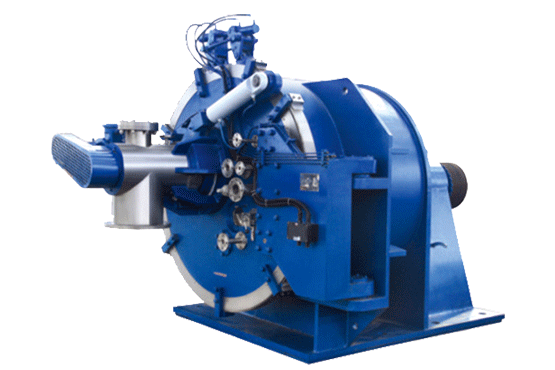

| GKF AUTOMATIC HORIZONTAL SCRAPER CENTRIFUGE | Saideli GK(F) series automatic scraper centrifuge is mainly used in solid-liquid separation of raw materials, intermediates and end products in the... | |

| Products | SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops... | |

| FSD CENTRIFUGAL DRYER | This industrial centrifugal dryerintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly su... | |

| Products | SAIDELI-PROFESSIONAL CENTRIFUGE MACHINE MANUFACTURER Jiangsu Saidelicontinuously develops high-tech and top-quality products which include Industr... | |

| HR Pistons Pushing Centrifuge | When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher centrifugewill be led to the... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |