Screw Sorting Machine

The Screw Sorting Machineis an advanced equipment designed for automated sorting of screws. It utilizes sensors and sorting mechanisms to accurately categorize screws based on size, shape, or custom criteria. This screw sorting machine increases efficiency in assembly processes by eliminating the manual sorting effort, reducing errors, and ensuring the right screws are readily available for production. It is a valuable tool for manufacturers in various industries. Investing in a Screw Sorting Machine means fewer delays, less waste, and a smoother, more reliable production flow. Don’t let manual sorting slow you down. Embrace the future of manufacturing with our Screw Sorting Machine for sale and take the first step towards a more efficient, error-free production line.

Benefits and Cost Savings of Using a Screw Sorting Machine

Using a screw sorting machine in manufacturing processes offers numerous benefits and can lead to significant cost savings.

One major benefit is increased efficiency. Screw sorting machines eliminate the need for manual sorting, saving valuable time and labor. They can accurately and quickly sort large quantities of screws, resulting in improved production rates and reduced bottlenecks.

Another advantage is improved accuracy. These machines ensure that each screw meets the specified requirements, eliminating the risk of using incorrect or faulty screws in the assembly process. This leads to enhanced product quality and reduces the likelihood of defects, rejections, and costly rework.

The implementation of a screw sorting machine also helps in reducing labor costs. Manual sorting is a time-consuming task that requires a skilled workforce. By automating the sorting process, manufacturers can reallocate labor to more value-added tasks, reducing labor expenses and increasing overall productivity.

Furthermore, screw sorting machines contribute to minimizing downtime. With their efficient sorting capabilities, they ensure a steady supply of screws to the production line, reducing interruptions and downtime caused by depleted inventory or incorrect screw placement.

Cost savings can also be achieved through inventory management. Screw sorting machines allow for better control and tracking of screw inventory, preventing overstocking or understocking. This leads to optimized inventory levels, reduced storage costs, and more efficient use of working capital.

Lastly, by reducing human error and enhancing quality control, screw sorting machines minimize the risk of product recalls, customer complaints, and associated costs. Consistently delivering defect-free products can enhance customer satisfaction and foster long-term relationships, which directly impacts the bottom line.

In conclusion, the use of a screw sorting machine offers numerous benefits, including increased efficiency, improved accuracy, reduced labor costs, minimized downtime, better inventory management, and enhanced product quality. These advantages ultimately result in significant cost savings and improved profitability for manufacturers.

Screw Sorting Machine Features

01

Versatile Sorting Capabilities

Screw sorting machines are versatile and can sort screws and other fasteners based on multiple characteristics, such as size, length, thread type, head type, and material. The flexibility of Rainbow screw sorting machines allows them to handle a wide range of fastener types and specifications, making them adaptable for different production needs.

02

High Sorting Speed

One of the primary characteristics of screw sorting machines is their ability to sort fasteners quickly and efficiently. This fastener manufacturing machine can process large quantities of screws per minute, which is crucial for maintaining high production rates in manufacturing environments.

03

Accurate Sorting

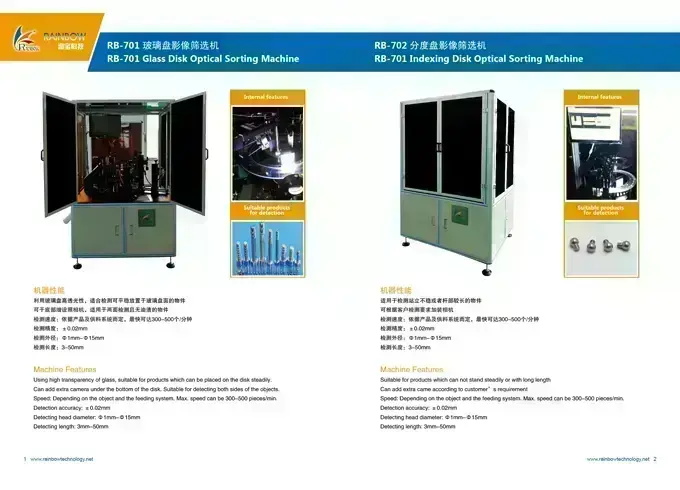

Precision and accuracy are essential characteristics of screw sorting machines. They use sensors, cameras, or other detection methods to identify and sort screws with high precision, ensuring that each fastener ends up in the correct bin or container. This accuracy minimizes errors in assembly and production.

04

User-Friendly Interfaces

Many screw sorting machines feature user-friendly interfaces with touchscreen controls and intuitive software. Operators can easily set sorting criteria, adjust parameters, and monitor the sorting process in real-time. This characteristic simplifies operation and reduces the learning curve for users.

05

Durability and Reliability

Screw sorting machines are built to withstand the demands of continuous operation in industrial settings. Automatic screw sorting machines are constructed from durable materials and designed to be reliable, minimizing downtime and maintenance requirements. This characteristic is essential for ensuring consistent production.

FAQs About Screw Sorting Machine

Q

Can the Screw Sorting Machine handle different types and sizes of bolts?

A

Yes, screw sorting machines can typically be adjusted to manage a variety of bolts and screws by modifying settings and tailoring the sorting parameters to meet specific requirements.

Q

What level of accuracy can be achieved with an optical sorting machine?

Q

Can this screw sorting machine be integrated into an existing production line?

Q

Can Screw Sorting Machines detect defective screws?

Q

How to Choose a Suitable Screw Sorting Machine?

Q

How to maintain a Screw Sorting Machine?

As a fastener equipmentmanufacturer, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

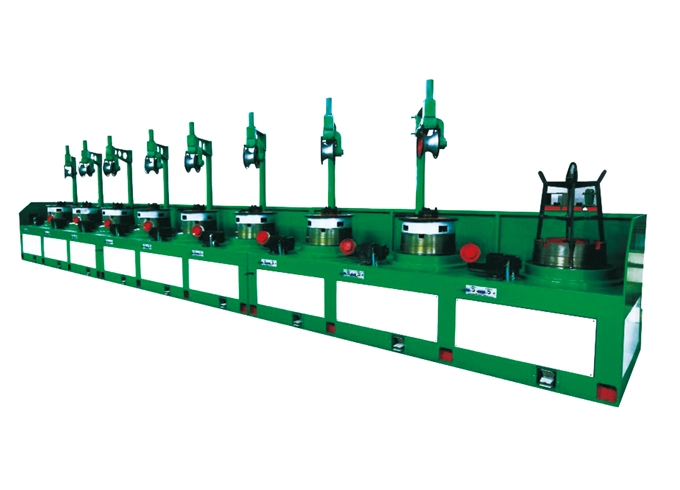

| Fine Wire Drawing Machine | Fine Wire Drawing Machine The Fine Wire Drawing Machineis an advanced machinery designed for precise and efficient reduction of metal wires, resul... | |

| Mesh Belt Furnace | The Mesh Belt Furnaceis a specialized industrial furnace used for heat treatment processes. It features a continuous mesh belt conveyor system that... | |

| Screw Washer Assembly Machine | Screw Washer Assembly Machine The Screw Washer Assembly Machineis a cutting-edge automation solution designed to streamline the process of screw a... | |

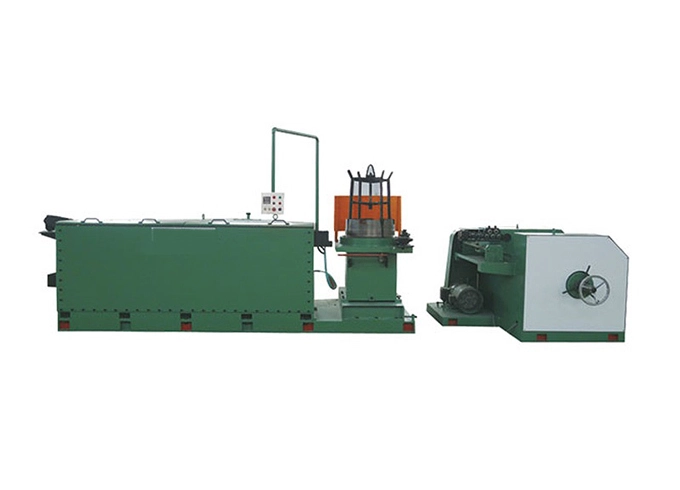

| Straight Line Wire Drawing Machine LZ9/1200+Spool Take-up Machine GS 1250 | Straight Line Wire Drawing MachineLZ9/1200+Spool Take-up Machine GS 1250 The Straight Line Wire Drawing Machine LZ9/1200+Spool Take-up Machine GS ... | |

| Rainbow Punches And Dies | Punches and diesare crucial tools in the metalworking industry for cutting, shaping, and forming metal materials. A punch applies force to a workpi... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |