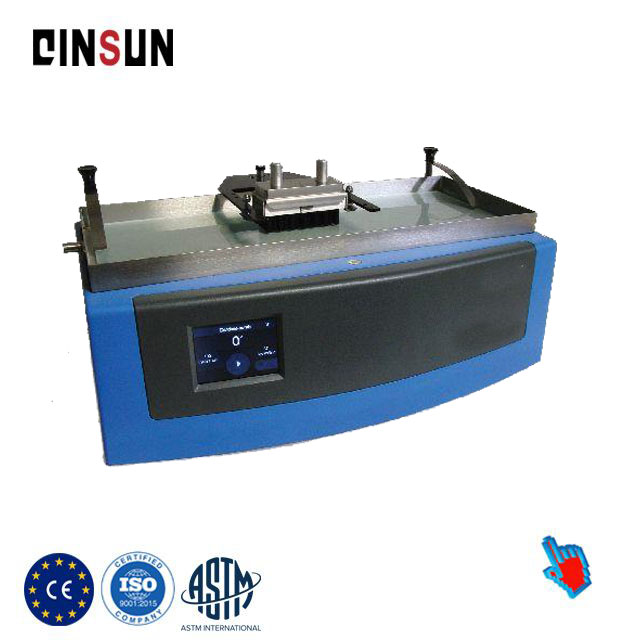

Fabric Downproof Tester(Rolling Box)

Fabric anti-drilling velvet testerMainly used in the production of down products and fabric of the anti-drilling velvet test, used to assess a variety of fabrics to prevent drilling or feathers from the joints between the drilling performance.

Meet the standard:GB / T 12705

The main parameters:

1. Rotary box body size: 450 × 450 × 450mm

2. Rotary box speed: 45r / min, positive and negative

3. Rotation setting: 1 ~ 9999 times, LED display

4. Rubber ball: 10 / box; Hardness: 45 ± 10; Weight: 140 ± 5g; Material: Butyl rubber

5. Power: AC 220V ± 10%, 50Hz, 200W

6. Dimensions: 850 × 650 × 800mm

7. Weight: 60kg

Fabric anti-drilling velvet tester Main features:

1. Computer processor control, equipment operation to terminate the automatic shutdown alarm;

2. Counter: LED liquid crystal display can be set, and with a calibration system to ensure the stability of equipment operation;

3. Transparent polyacrylonitrile safety cover, easy to implement the observation of the operator;

4. The whole machine is 316 stainless steel, strong and generous.

Test principle:

1, the first sample made of bags, built a certain quality of the down, put the test instrument of the rotating box, while in the rotating box is also loaded with hard rubber ball;

2, the rotating box to a certain speed of rotation, the rubber ball from a certain height fall, the impact of the sample, to simulate the down products in the course of taking a variety of extrusion, rubbing, collision and so on;

3, by counting the number of drill holes drilled from the inside of the sample to assess the fabric's anti-drilling performance.