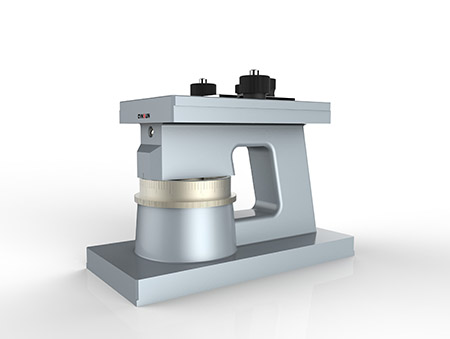

Launderometer/Washing Fastness Tester

Standards:

ISO 105 C01 C02 C03 C04 C05 C06 C08 D01, BS 1006 C01 C02 C03 C04 C05, AATCC 28 61 86 132 151 190, NEXT TM2 3 5, M&S C4 C5 C10A P3B, GB/T 3921 5711, FTMS 191-5610

Applications:

For conductingColor fastness to washing, to dry cleaning, at temperatures up to 95°C, also including the colorfastness of dye.

Product Information:

The Double-Cylinder Launder-Ometer is an ideal machine for checking fastness to washing, dry cleaning of coloured

textile samples. The two separated cylinders are equipped independent control panels, whichis able to conduct the two

tests with different temperature simultaneously . Control system equips with electronic light touch switch , liquid

crystal display Menu without mechanical contact , safe and reliable for operators. Sample frame rotation is stable, it’s

convenient for changing washing Container or washpot . Machine contains two kinds of washing cups(500ml and 1200ml), and

each cylinder has 24 slots for cup Assembly (12 with each size) for different test requirement. Heating device have a

long life with no noise, could give an accurate temperature.

Technical Parameters:

1.Test container station: (12+12)×2;

2.Rotating speed: 40±2 rpm;

3.Control mode: CNC, independently control the temperature and time of two test cylinders simultaneously, procedure

could be set arbitrarily;

4.Dimension of sampling cup: 1200±10ml and 550±10ml;

5.The function of Inching rotation with each test case ;

6.The function of automatic alarm as the test finished;

7.Material: stainless steel of 316;

8.Fast exchanging sample cups;

9.The temperature control is up to 98℃;

10.Temperature tolerance: -/+0.3℃;

11.Temperature is controlled by microprocessor, and displayed on the interface with time;

12.Test cover with effect of double sealed heat preservation, which help to minimize heat loss and reduce the heating

frequency, make an effective protection of the heating tube service life ;

13.Pneumatic strut is adopted on the Hinged lid , which is more humane , manpower saved, and has an effective

protection for the operators;

14.The alarm function of preventing overflow;

15.The alarm of Anti-dry technology for protecting the machine;

16.The hidden snakelike pressure relief can help to refrigerate the steam to cooling water when internalpress is too

high;

17.A forklift can make movement for the machine.

Accessories and Consumables:

1.The machine of Double-Cylinder Launder-Ometer

2.Stainless steel sampling cups of 550ml: 16

3.Stainless steel sampling cups of 1200ml: 16

4.Stainless Steel Balls for washing test: 2000

5.container seals for stainless steel sampling cups of 550ml: pack of 20

6.Washing sealing washer for stainless steel sampling cups of 1200ml: pack of 20

7.Drycleaning sealing washer for stainless steel sampling cups of 550ml: pack of 20

8.Drycleaning sealing washer for stainless steel sampling cups of 1200ml: pack of 20

9.Stainless steel drycleaning discs:50

10.DW multifiberadjacent fabric:pack of 10m

11.AATCC multifiberadjacent fabric: pack of 1m

12.ECE standard detergent(non- fluorescent):2 tub

13.AATCC standard detergent(non- fluorescent):2 drum