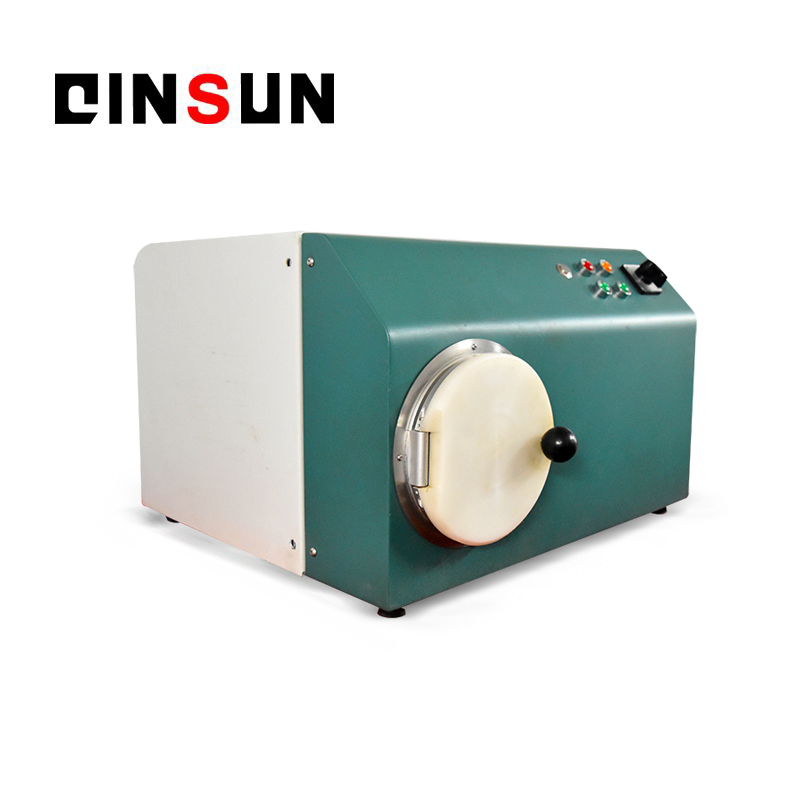

Seam Fatigue Tester

Standards:

Toyota TSL5101G Section 3.7,GMW 3405,Nissan M-0154,Ford Motor Co. BN 106-02,TSL5100G Section 4.22

Applications:

The seam fatigue tester is designed to evaluate the fatigue resistance of seam on the material which is applied on the surface of automotive seat.The surface material of car seat (leather, synthetic leather, fabric, etc.) is often stitched together. The stitching strength of the material seam and the fatigue strength of the seam can directly affect the service life of the seat.The strength and life of the joint of the test material can effectively predict the life of the seat and provide the direction of improving the service life.

Product Information:

Product Information:

The Seam Fatigue Tester is a two station bench top machine, used for evaluating fabric or leather seating materials resistance to tearing or needle hole elongation of a sewn seam. Each station includes a pair of suitable clamps for attaching the test sample. A height gage is used to set the sample clamp separation distance of the 140mm for each station.One or two stations can be tested at a time.

The sample is placed on the clamp and the position of the left and right clamping device makes the test sample spacing meet the standard requirements.Set the test cycle numbers and start the test. The Decelerator will drive the middle clamp holder to do the reciprocating movement. The left and right clamp holders are connected with a 3kg load. During the reciprocating motion of the middle clamp holder, the left and right samples will experience a process of loading and unloading of the weight load at the time of around one motion cycle.Theproximity switch connectedwith the counter records the clamping device motion cycle, and the test automatically stopped when reaching the set number of cycles.The fatigue resistance of the joints was measured by the measurement of the change of seam opening in the material seam.

Seam Fatigue Tester TestingMethod:

The operator installs the set up gage between one pair of sample clamps on a station. The sewn test sample is aligned and clamped into position.The set up gage is removed and installed on the second station. The second sample is aligned and clamped into position and the set up gage is removed. The desired number of test cycles is entered on the cycle counter and the test is started. Once this cycle count is reached the machine will automatically stop. Test samples are visually evaluated.

Features:

1.Mechanical components are constructed of non-corrosive Aluminum and Stainless Steel.

2.Durable Powder Coat and Anodized finishes.

3.Precision ball and needle bearings.

4.Programmable count-up controller with automatic stop.

5.Adjustable jog and test speed controls.

6.Adjustable weight shelf height.

7.Adjustable clamp separation distance.

8.Vented Protective Cover protects operator hands from pinch points.

Technical Parameters:

1.Stations: 2;

2.Testing load: 3kg;

3.Speed: 30 cycles/minute;

4.Cycle counter: 4 digits (standard of 2500);

5.Stroke: 140mm;

6.Sample clamp separation: 120, 124, 140, adjustable;

7.Sample clamp width: 50mm;

8.External dimension: 13×31×17 inches (L×W×H);

9.Weight: 50kg (110lb).

Loading