Heavy Engineering Parts

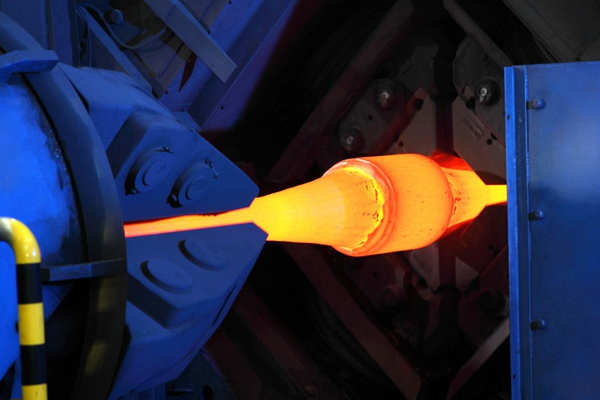

As professional dragline parts suppliers, WALKSON specializes in manufacturing quality heavy equipment aftermarket parts, spare parts for heavy equipment, large size mechanical components for Customers for various industrial sectors. we have delivered high-quality cast, welded, and forged parts for many customers. We offer tailor-made solutions and components up to 50 tones component of casting and forging.

With more than 20000 m2 of shops and machine tools, modern manufacturing and testing equipment and customer-focused philosophy, WALSKON, professional in heavy equipment replacement parts and spare parts for heavy equipment, is your reliable partner for subcontracting when it comes to Heavy Equipment. We have various heavy forging products for sale and supply complete solutions: engineering, sourcing, manufacturing, surface finishing, testing, certification.

Dragline excavator walking cam

Dragline excavator camshaft

Dragline excavator forging links

Dragline excavator walking frame

Split girth half gear

eccentric gears

Dragline Stablizer Link

Dragline Stabilizer Link, also known as dog bone is a particularly important component used on the dragline excavator. One end of the stabilizer link is connected the walking shoe of the dragline excavator, the other end is connected to the walking cam. It is a key component in the dragline excavator walking mechanism. WALKSON supplies forged dragline stablizer link as a perfect replacement for welded links to increase the lifecycle of the component.

Dragline Walking Frame

Dragline walking frame, together with walking cam and cam shaft / propel shaft are the most important parts for dragline walking mechanism.

Dragline Walking Cam

Dragline walking cam, together with walking frame and cam shaft / propel shaft are the most important parts for dragline walking mechanism.

Propel Shaft

Dragline propel shaft, together with walking frame, walking cam and walking shoe are the most important parts for dragline walking mechanism.

Bubble Shaft

WALKSON can provide forged shafts, forged Crankshafts and forged stepped/bubble shafts of carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum, copper, and tool steel conforming to ASTM, AMS, AISI, SAE, and Other industry approved specifications. Forged shafts range in diameter from 100mm to 1000mm and in length to 10m. Other Forged Shaft shapes produced include forged spindle, round bar. We can also produce hollow shafts too.

Other supplier products

|

|

Shredder Hammer Tips/ Knife Edges |

Our shredder hammer tips are bi-metallic composites having 700BHN hardness and available in various sizes and shapes.

Our products are widely used... |

|

|

Rigging Components |

Rigging Components WALKSON manufacture most parts of the dragline rigging and structural component for buckets used in the surface mining industry.... |

|

|

Dragline Walking Cam |

Dragline walkingcam, together with walking frame and cam shaft / propel shaft are the most important parts for dragline walking mechanism.

Why C... |

|

|

Ground Engaging Tools |

Ground engaging tools definition: Ground Engaging Tools (G.E.T) are wear parts with high impact and high abrasion resistance ability. High-performa... |

|

|

Closed-die Forging(Impression-die) |

Closed die forging process is also called as impression die forging, is a kind of forging method that can be achieved by closed die forging press.

... |

All supplier products

Same products