BMC/SMC Molds

Custom high Precision Compression/bulk molding compound manufacturingwith fast lead time

BMC/SMC Mould Manufacturer

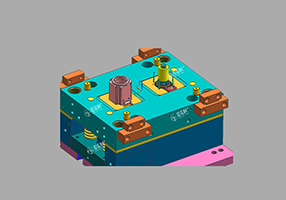

We mainly use bmc injection moldingand pressure molding as the methods. When designing the flow channel and parting surface, we think that the cavity pressure should be as small as possible, especially some small ribs, as well as the smooth exhaust, the discharge position, shape, and material flow direction, which would all be fully considered. And the active exhaust must be complete with an overflow. We guarantee the appearance and strength. With the Vacuuming structure, the mold temperature balance is consistent as the appearance and strength of the product shall be guaranteed as well.

Waiwai Tree is a professional smc molding and manufacturingprovider. We provide you with SMC plastic moldingand BMC injection molding. You can know difference between SMC and BMC from us. If you are interested in smc mould, and contact us to get more information now!

Types of BMC/SMC Molds

Motor Mold

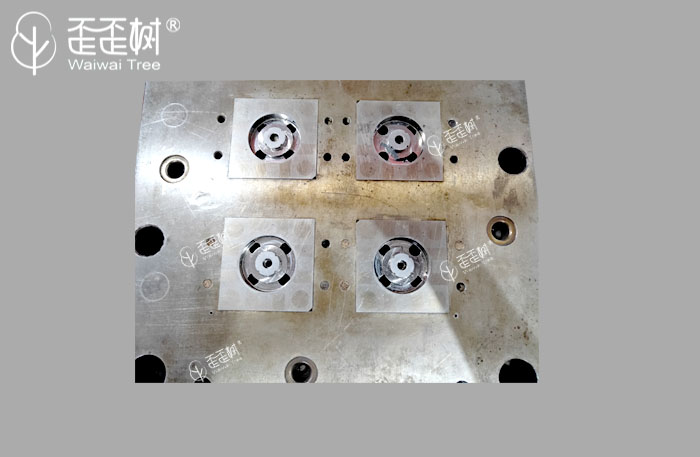

Motor Mold is designed mainly for injection molding with the runner and parting surface would be precisely small.

Servo Motor Mold

BMC Plastic-Envelop Motor Mould

Over Mouding

BMC Rotor Mould

BMC Stator Mould

Air Conditioner Motor Mould

Refrigerator Motor Mould

Washing Machine Motor Mould

DC Motor Mold

AC Motor Mould

Automotive Motor Mould

Power/Electic Tool Rotor Mould

Hood Motor Mould

Motor End Cap Mould

Motor Bracket Mould

High Voltage Electrical Product Mould

High Voltage Electrical Product Mould is a featured products and the mold temperature can be balanced with a vacuum sructure.

High Voltage Circuit Breaker Mould

High Voltage Fuse Mold

High Voltage Switch Box Mould

High Voltage Transformer Mold

High Voltage Battery Box Mould

Low Voltage Electrical Appliance Mould

Low Voltage Electrical Appliance Mould is mainly used for pressure molding and for the movable exhaust and designed with a overflow trough.

Low Voltage Circuit Breaker Mould

Low Voltage Fuse Mold

Low Voltage Switch Box Mould

Low Voltage Transformer Mold

Low Voltage Electrical Valve Mould

Low Voltage Relay Mould

Auto Parts Mould

Auto Parts Mould sloves the problem of ligh-weight, aging and other leakage issues as well as reduces more costs but improves the quality.

Car Bumper Moulding

Battery Box Mould

Car Light Mould

Seat Mould

Engine Intake Pipe Mould

Electric Control Box Mould

Frame Moulding

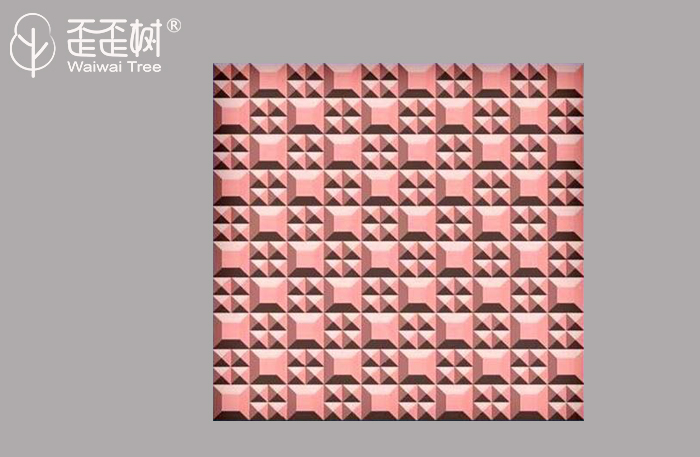

Frame Moulding has high plasticity with a precise size but high insulation ability and high temperature resistance.

Inverter Frame Mould

Difference Between SMC and BMC

Difference Between SMC and BMCSMC is a combination of long chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a malleable sheet material. Processing of SMC of is typically done by compression or injection molding.

Sheet Molding Compound (SMC) is a compression molding compound often used for larger parts where higher mechanical strength is needed. SMC is a fiber reinforced thermoset material. Glass reinforcement is between 10% and 60%, and glass length is slightly longer than Bulk Molding Compound (BMC) - between 1/2-inch and 1-inch (25mm).

BMC is a combination of short chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a bulk material. BMC is suitable for either compression or injection molding.

Bulk Molding Compound (BMC) is a thermoset plastic resin blend of various inert fillers, fiber reinforcement, catalysts, stabilizers, and pigments that form a viscous, 'puttylike' injection molding compound. Bulk Molding Compound (BMC) is highly filled and reinforced with short fibers. Glass reinforcement represents between 10% and 30%, with glass length typically between 1/32-inch and 1/2-inch (12.5mm).

Bulk Molding Compound (BMC) is a thermoset plastic resin blend of various inert fillers, fiber reinforcement, catalysts, stabilizers, and pigments that form a viscous, 'puttylike' injection molding compound. Bulk Molding Compound (BMC) is highly filled and reinforced with short fibers. Glass reinforcement represents between 10% and 30%, with glass length typically between 1/32-inch and 1/2-inch (12.5mm).

SMC Material & Compression Molding Processes

The basic process of the compression molding process is to place a certain amount of the pre-treated molding material into a preheating compression mold, and apply a higher pressure to fill the mold cavity with the molding material. Under the predetermined temperature conditions, the molding material is gradually solidified in the cavity, and then the SMC product is taken out from the stamper, and the necessary auxiliary processing is performed to obtain the final product.

The pressing process of the composite molded product is a process of solidifying into a product in a cavity after the binder is loaded or heated under the condition that the curing agent is present or heated. Like smc plastic molding, smc injection molding temperature, molding pressure and mold exhaust, temperature balance, and mold structure all affect the quality of SMC products. It is necessary to determine the best solution under the consideration of various influencing factors.

BMC Material & Injection Molding Processes

BMCcompoundis the initial abbreviation of English Bulk Molding Compound, and the Chinese name is a group molding compound. Pre-mixed into a paste by unsaturated polyester resin, low shrinkage/low profile additive, initiator, internal mold release agent, mineral filler, etc., and then added thickener, colorant, etc., with different lengths of glass fiber, in special Stirring in the kettle is carried out to carry out a thickening process, which finally forms a dough-like intermediate material which can be used for molding and injection molding.

The BMC injection molding process basically follows the same rules as the injection mold. However, SMC and BMC molds also have different characteristics from injection molds, such as flow path, exhaust, heating, cavity pressure and balance, parting structure, mold steel used and precision, shrinkage and injection molds. Differently, the BMC mold is molded at a high temperature, and the plastic mold is molded at a normal temperature. As one of sheet molding compound manufacturers, Waiwai Tree can offer high-quality bmc injection moulds at very competitive prices, contact us for more information!

BMC/SMC Mould Manufacturing

SMC and BMC compositemolds require heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Send product request

Other supplier products

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safet... | |

| Flange Molding | Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Sinc... | |

| BMC/SMC Motor | BMC/SMC Electric MotorsDescription Motor BMCreplaces traditional iron and aluminum, reduces the process, seals more, and has higher safety facto... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| Low-Voltage Electrical Products | Low Voltage Electrical Appliance Mould Manufacturer Mainly refers to circuit breakers, fuses, switch boxes, transformers, electric control boxes, ... |

Same products

| Windshield Film | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Windshield Film The automotive windshield film is installed on the outside of the windshield and ... | |

| Metallized Window Tint | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Metallized Window Tint The multi-layer magnetron sputtering double silver series has the charact... | |

| Matte PPF | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Matte PPF Mattepaint protection filmhas the beauty of a matte finish and a better natural light.... | |

| Textured Film | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Textured Film The TexturePaint Protection Filmsnot only has the texture of carbon fibre, but als... | |

| Customizable Electric Tonneau Cover | Seller: Guangzhou Zhenlonghui Auto Accessories Co., Ltd. | Customizable Electric Tonneau Cover The advanced all-electric retractable Tonneau cover gives yo... |