METAL WELDING

Metal weldingis a manufacturing process and technology to join metals or other thermoplastic materials such as plastics by heating, high temperature or high pressure. There are many types of custom metal welding. TIG(Tungsten Inert Gas), MIG (Metal, Inert Gas), GMAW (Gas, china metal welding), and arc welding are the most common welding methods. Hunkmachining offers metal welding service for various kinds of metals ranging from stainless steel and carbon steel. Our engineers will assist you with design to after sales. We are capable of designing welding tooling and custom gauge. Along with advanced welding equipment including a welding robot, we will offer the best welding solution for your project.

WHAT IS USED IN WELDING OF METALS?

Steel

Steel is the most common metal used in welding. It has many properties that are proper for welding processes. It has high tensile strength that can undertake a mass stress. There are stainless steel, carbon steel and low carbon steel for choice in welding depending on the product. Mild steel is especially easy to weld as it has an outstanding ductility. Besides, the price of steel is cheap which is one of the reasons it is so popular in welding.

Aluminum

Widely used on vehicles, aluminum has a strong corrosion resistance like stainless steel. Although its melting points is lower than steel, it requires more heat for welding. TIG welding is one of the best choices when welding aluminum.

Copper

Copper has good electrical conductivity, heat conductivity and corrosion resistance. It does not need to be preheated before welding because of its high heat conductivity. Sometimes it is treated with manual arc welding for lower cost. However, that may lead to unreliable quality. Therefore, most companies use TIG or gas metal arc welding to weld copper.

Other materials

Many other materials can also be found in welding process(e.g. brass, titanium, cast iron, magnesium alloys). Some of these materials require specific methods. Magnesium alloys as an example, should be welded by AC-TIG welding. Equipment and welders need to be more qualified to manage that.

If you are looking for a reliable metal welding supplier, don't hesitate to contact us!

If you need any kinds of metal welding service, please contact us, as a professional metal processing supplier, Hongkun is willing to offer you high quality products.

Send product request

Other supplier products

| METAL STAMPING | Stamping is a cold stamping process, which is to cut, bend or shape the material into the finished shape and size in accordance with the mold with ... | |

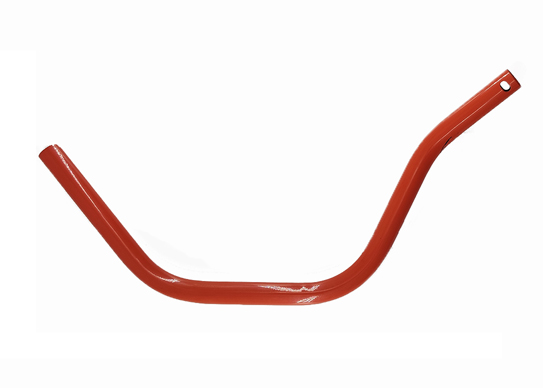

| MOWER DRIVE ARM IN MOWER DRAG LINK | It is a mechanical assembly used to control the steering of lawn mower drag link, consisting of drive arm, steering arm, steering knuckle, etc. Mos... | |

| MIG WELDING - GAS METAL ARC WELDING (GMAW) | China mig welding(Melt Inert-Gas Welding) is a welding method that uses the molten electrode and the external inert gas (Ar or He) as the arc mediu... | |

| METAL DEEP DRAWING | Metal deep drawing chinarefers to a kind of machining process in which a certain shape of flat blank obtained after blanking is stamped into variou... | |

| MOWER PARTS | Hunkmaching has been manufacturing oem mower parts used on many top brands including Bad Boy Mowers and John Deere. We offer good quality parts ran... |

Same products

| BLIIOT BL360 Industrial ARM Computers Powered By NXP Mx8m Mini with Quad Core Cortex A53 M4 | Seller: Shenzhen Beilai Technology Co., Ltd. | BL360 Industrial ARM Computers built on NXP i.MX8M Mini with quad-core Cortex-A53+M4. As a Indust... | |

| BLIIOT ARMxy BL350 Industrial Embedded Computer With Ti Sitara Am62x Processor | Seller: Shenzhen Beilai Technology Co., Ltd. | BL350 is an Industrial Embedded Controller powered by the TI Sitara AM62x processor with up to qu... | |

| BLIIOT BL460 Powered by Raspberry Pi CM5 Industrial Embedded Computer | Seller: Shenzhen Beilai Technology Co., Ltd. | Industrial AI Embedded Computer BL460 based on the Raspberry Pi CM5 module and compatible with th... | |

| 30-160KW 10-30Khz Induction Heating Machine | Seller: Chengdu Duolin Electric Co.,Ltd | 30-160KW 10-30Khz Induction Heating Machine Ultrasonic induction heating equipment IGBT inverte... | |

| Vertical Bendable Neon Flex LED Strips 15X16mm | Seller: Shenzhen Blue Diamond Technology Co.,Ltd | Vertical Bendable Neon Flex LED Strips 15X16mm This Vertical Bendable Neon Flex LED Strips are v... |