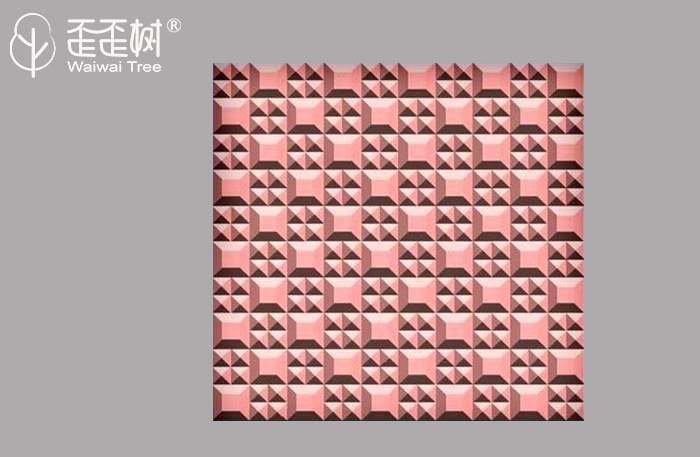

BMC, SMC, GRP, GFK Building & Decoration Materials

Aobang composite Building & Decoration materialis divided into: BMC building decoration material, SMC building decoration material, GRP building decoration material, GFK building decoration materials.

Building decoration materials may have heard of commonly used materials such as sandstone and cement. BMC, SMC, GRP, and material gfkhave been heard by few people. It is a new type of bmc materials. What are the advantages?

It can be known that it is resistant to water and oil and excellent corrosion resistance, and its heat resistance and good electrical properties are its advantages, making it stand out in the highly competitive material market. In addition, it can be further found that the composite material has higher requirements for the post-use environment than other materials.

We can provide GRP building productsfor you.Aobang technology limitedhas a technical team engaged in many years of production and R&D, and has the industry-leading expertise and technical level. We are dedicated to meeting the needs of our customers and highlighting the value that is given to our customers.To learn more about bulk molding compound manufacturing, please contact us!

Send product request

Other supplier products

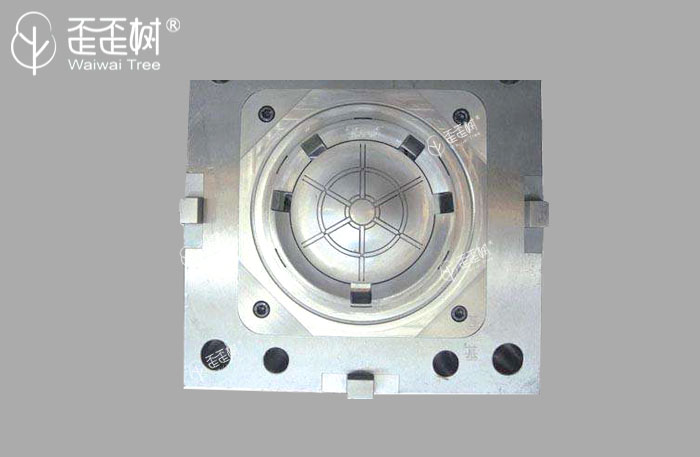

| Development System of BMC Rotor Mould | At present, in the development process of BMC mold, the BMCcompositematerial is thermosetting resin. In the process of mold heating and curing, bec... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... | |

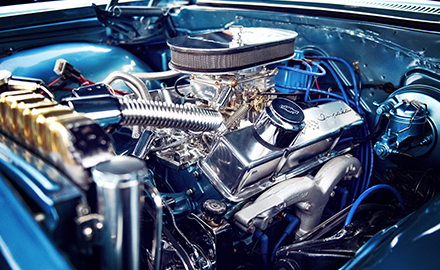

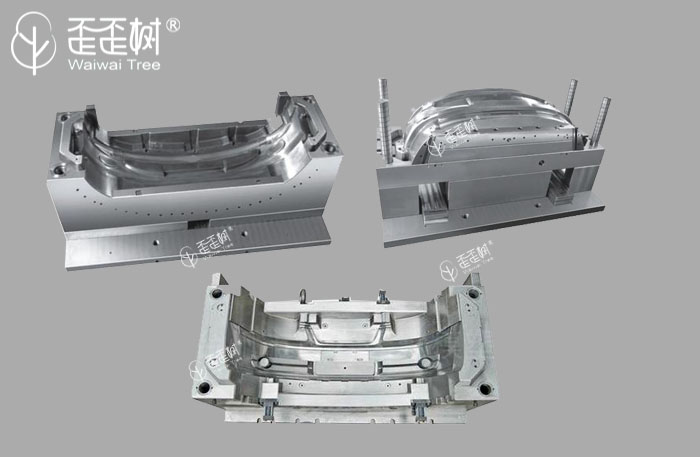

| Auto Parts Mould | Auto Parts Mould Features Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the... | |

| Shell Moulding | Shell Moulding Description BMC/SMC shell moulding is mainly injection molded. The application of SMC in anti-explosion electric appliances change ... |

Same products

| Vacuum Pum Three-Phase Asynchronous Motor | Seller: Taizhou Sulin Electromechanical Co., Ltd. | The Vacuum Pump three-phase asynchronous motor is a specialized motor designed to power vacuum pu... | |

| IndustrialFlex Worm Gear Motor | Seller: Ruian Zhanpeng Machinery Co., Ltd | IndustrialFlex Worm Gear Motoris built to support equipment requiring smooth motion transmission ... | |

| TorqueBalance High Precision Gear Reducer Motor | Seller: Ruian Zhanpeng Machinery Co., Ltd | TorqueBalance High Precision Gear Reducer Motorprovides controlled speed output and flexible redu... | |

| High Precision Gear Reducer Motor | Seller: Ruian Zhanpeng Machinery Co., Ltd | The High Precision Gear Reducer Motoris an advanced power transmission solution that combines a h... | |

| Philips TTF Motor 9498 396 00197 | Seller: KF-SMT Technology Co., Ltd | Part Name: PHILIPS TTF MOTORPart NO: 9498 396 00197 Delivery 1-5working days ... |