FINNED TUBES

The radiant fin tube, steel fin tube, electric fin tube is an efficient heat transfer element, the core and key component of the common air cooler, its quality directly affects the performance of the common air cooler, and the cost of the finned tube in the common air cooler accounts for about 60% or more of the total cost of the tube bundle.

Types Of Finned Tubes

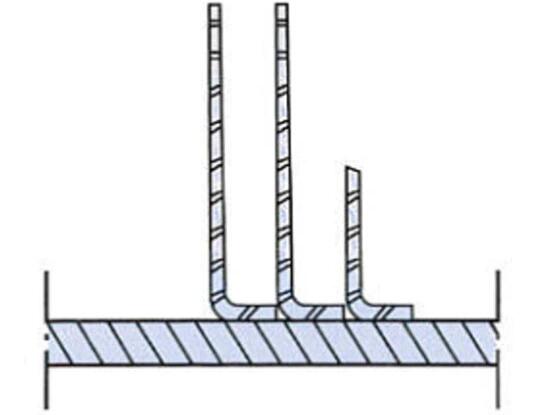

L-Type Finned Tubes

LL Type Finned Tube

KL Type Finned Tube

G-Type Finned Tube

DR Type Finned Tube

Introduction

Finned tubes are specialized heat transfer components used in various industries and applications. These tubes are typically made of a metal such as copper, aluminum, or stainless steel and feature extended surfaces, called fins, attached to the outer surface of the tube. The fins significantly increase the surface area of the tube, which enhances heat transfer efficiency.

Finned tubes are commonly used in finnedtubeheatexchanger , air coolers, condensers, and boilers, where efficient heat exchange is crucial. The fins facilitate the transfer of heat between the fluid flowing inside the tube and the surrounding air or fluid. By increasing the surface area available for heat transfer, finned tubes enable quicker and more effective heat dissipation or heat absorption.

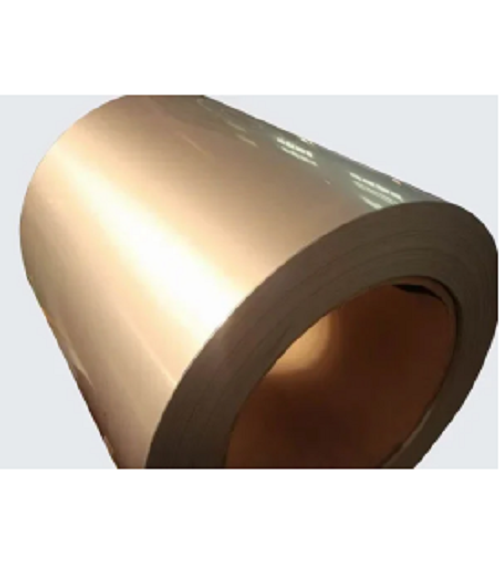

Can Finned Tubes Be Made Of Different Materials?

1 2 copper fin tubes can be made of different materials depending on the application. Materials such as carbon steel, stainless steel, copper, and aluminum are commonly used in the manufacture of finned tubes. In some cases, a combination of metals may be used to optimize heat transfer characteristics while minimizing cost.

What Is The Process Used To Manufacture Finned Tubes?

The manufacturing process for finned tubes involves taking a basic tube and attaching fins to its exterior surface. Various methods such as roll bonding, extrusion, and welding can be used to attach the fins. The tube is first cleaned to remove any impurities or contaminants that could compromise adhesion of the fins. The fins are then bonded to the tube using heat or pressure or a combination of both. The tube is then tested and inspected to ensure that it meets required specifications.

How Are Finned Tubes Maintained?

Finned tubes require regular maintenance to ensure their peak performance and longevity. Regular maintenance includes cleaning, inspection, and repair. The fins, tubes, and the interior of the heat exchanger must be regularly inspected and cleaned to remove debris that may reduce the transfer of heat. The fins may need to be straightened if they become damaged to optimize heat transfer. In some cases, fins may need to be replaced if they become damaged beyond repair. It is important to ensure that the replacement fins have the same specifications and dimensions as the original fins to ensure proper operation. A preventative maintenance schedule can help to ensure that finned tubes are regularly maintained to optimize their operation and lifespan.

As one of tower fan manufacturers, we will do our best to meet all the needs of customers.

Other supplier products

|

|

Titanium Coil |

Titanium Coil

Titanium coilis a hollow, cylindrical structure made of high-strength, lightweight titanium metal, wound into a coil shape. It is us... |

|

|

Molybdenum Screw. |

Molybdenum screwis a fastener made of molybdenum, a refractory metal with excellent strength, corrosion resistance, and thermal stability. Molybden... |

|

|

METAL SPUTTERING TARGET |

Metal pt sputtering targetand au sputtering targets are critical components of the sputtering process used in the manufacturing of thin films for s... |

|

|

Molybdenum Parts |

Molybdenum partsare machined or fabricated parts made of molybdenum, a refractory metal that possesses excellent properties such as high-temperatur... |

|

|

Plate Heat Exchanger |

Plate heat exchanger is a highly efficient heat exchange system comprised of a series of metal sheets with a specific corrugated shape. These sheet... |

All supplier products

Same products

|

|

Yoyik offer cooler GLC2-2.6 for steam turbine |

Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD |

""Yoyik offer cooler GLC2-2.6 for steam turbine YOYIK is a hi-tech company specializing in the pr... |

|

|

Recirculated Air Heating and Cooling Unit |

Seller: Fujian Air Technology Systems Co., Ltd |

When hot/cold water or stream passes the Recirculated Air Heating and Cooling Unit, the efficient... |

|

|

Water Chiller Manufacturers Near Me |

Seller: Shanghai Kendall Refrigeration Equipment Co., Ltd |

Headquartered in Shanghai, China, Kendall stands as a pioneer and leader in the refrigerati... |

|

|

Cold Room Solutions |

Seller: Shanghai Kendall Refrigeration Equipment Co., Ltd |

At , we bring over 20 years of expertise in refrigeration design, construction, installatio... |

|

|

Flooded Water-cooled Screw Chillers |

Seller: Shanghai Kendall Refrigeration Equipment Co., Ltd |

This has a compact structure which makes it easy to install and maintain. It is equipped wi... |