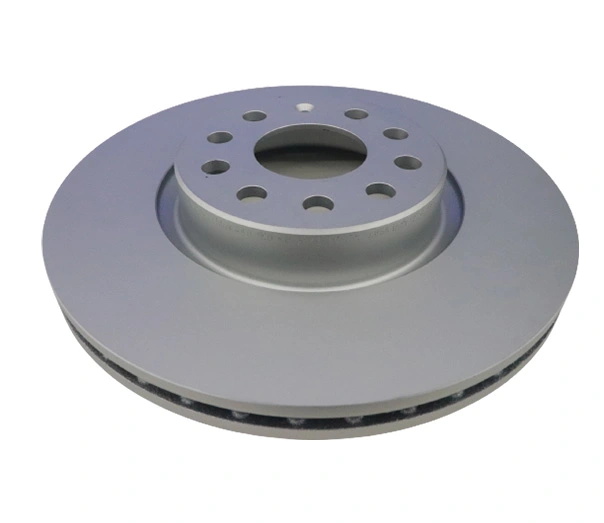

Brake Discs

A auto brake disc, also known as a auto brake rotor, is a circular component attached to a vehicle's wheel hub, providing you with the reliability and confidence you need on the road. When the brake pads clamp onto its surface, friction is generated, converting kinetic energy into heat to slow down or stop the vehicle. It plays a crucial role in modern disc brake systems.

Types of Custom Brake Discs

QBD001 Front Brake Disc

QBD002 Front Axle Brake Disc

QBD003 Front Axle Brake Disc

QBD004 Rear Axle Brake Disc

QBD005 Front Axle Brake Disc

QBD006 Front Axle Brake Disc

QBD007 Front Brake Disc

QBD008 Rear Brake Disc

QBD009 Front Brake Disc

QBD010 Front Brake Disc

QBD011 Rear Brake Disc

QBD012 Front Brake Disc

QBD013 Rear Brake Disc

QBD014 Front Brake Disc

QBD015 Front Brake Disc

QBD016 Front Brake Disc

QBD017 Front Brake Disc

QBD018 Rear Brake Disc

QBD019 Rear Brake Disc

QBD020 Front Brake Disc

Brake Disc Function

The auto brake disc china, also known as an auto brake rotor, plays a critical role in the braking system of a vehicle. Its main function is to provide a surface for the brake pads to grip onto and generate friction, which ultimately slows down or stops the rotation of the wheel.

When the brake pedal is pressed, hydraulic pressure is applied to the brake caliper, which in turn, causes the brake pads to clamp down on the brake disc quality. As the rotating disc is squeezed between the brake pads, friction is generated. This friction converts the kinetic energy of the rotating wheel into heat energy.

The disk brake rotor is designed to handle and dissipate this heat efficiently to prevent brake fade and maintain consistent braking performance. Brake discs are typically made of cast iron, as it has excellent heat absorption and dissipation properties. Some high-performance vehicles may use carbon-ceramic disc brake parts, which offer even better heat resistance and weight reduction.

By converting the kinetic energy into heat energy, the high-performance brake rotors and braking system slow down or stop the vehicle effectively. The brake disc's design, material quality, and proper maintenance are crucial to ensure its durability, effective friction, and overall braking system performance.

Brake Disc Material

Car brake discs, also known as rotors, are typically made from several different types of materials by auto brake manufacturers, each with its own characteristics and advantages. The most common materials used for custom-made brake discs include:

The choice of brake disc material depends on factors such as the type of vehicle, driving style, and intended use. Passenger cars and standard vehicles often use cast iron discs, while performance vehicles may opt for carbon steel or carbon ceramic discs to improve braking performance and reduce weight. It's essential to consider the specific requirements and recommendations of the vehicle manufacturer when selecting the appropriate brake disc material.

Auto Brake Disc Components

Rotor Surface:

The friction surface where auto brake pads make contact, generating friction to slow down the vehicle.

Ventilation Vanes:

Channels within the auto brake rotor that promote heat dissipation, preventing brake fade during heavy use.

Hub:

The central part of the custom made brake discs that connects to the wheel hub, enabling rotation.

Mounting Holes:

Holes around the hub for attaching the disk brake parts securely to the wheel hub.

Heat Sinks/Ribs:

Fins or ribs on the auto brake rotor's surface that aid in heat dispersion, preventing overheating and maintaining performance.

Flanges:

Raised edges on the auto brake rotor's perimeter that keep the brake pads centered and minimize lateral movement.

Coating/Finish:

Some disk brake rotors have coatings or finishes to protect against corrosion and enhance aesthetics.

Bobbins:

Pins or screws that secure the rotor to the hub and allow for some axial movement due to thermal expansion.

The Role of A Brake Disc in Auto Braking System

The auto brake disc is a pivotal component of the auto braking system, serving as the primary surface for friction generation. When the brake pedal is pressed, brake pads clamp onto the disc's friction surface, creating resistance and converting the vehicle's kinetic energy into heat energy. This frictional force decelerates the vehicle, allowing it to come to a controlled stop. The brake disc's design, material, and heat-dissipation features play a crucial role in preventing brake fade, ensuring consistent braking performance even under prolonged or heavy use. Its effective heat management, along with ventilation vanes and cooling channels, helps maintain optimal braking efficiency, contributing significantly to overall vehicle safety and stopping power.

Disc Brake Maintenance

Disc brake maintenance is crucial for ensuring optimal performance and safety. Regular maintenance helps to extend the lifespan of the brake components, prevent brake failure, and maintain consistent braking power. Here are some key aspects of disc brake maintenance:

- china brake disc factorycan provide a thorough assessment and perform necessary repairs or adjustments.

Remember, proper maintenance and prompt attention to any brake issues are crucial for your safety and the well-being of your vehicle. Regular inspections and servicing provided by brake rotor manufacturers will help ensure optimal braking performance and extend the longevity of your rear disc brakes.

Disc Brake Working Principle

The disc brake system operates on the principle of friction. When the brake pedal is pressed, hydraulic pressure is generated, which forces brake fluid into the caliper. This pressure causes the caliper to squeeze the brake pads against the rotating brake disc (rotor). The friction created by the brake pads pressing against the disc slows down or stops the rotation of the wheel. The heat generated by this friction is dissipated through the auto brake rotor, preventing the brakes from overheating. This friction-based mechanism allows for efficient and reliable braking performance.

Send product request

Other supplier products

| Clutch Cylinder | The car clutch cylinder, a crucial component in manual transmission vehicles, facilitates clutch engagement and disengagement. When the clutch peda... | |

| Drum Brake Assembly | A drum brake caliper assemblyis a braking system used in vehicles. It consists of a hollow drum attached to the wheel and brake shoes fitted inside... | |

| Brake Calipers | Anauto brake caliperis a component in a disc brake system of a vehicle. It houses the brake pads and clamps them against the brake rotor when the b... | |

| Brake Calipers | A auto brake caliper chinais a component in a disc brake system of a vehicle. It houses the brake pads and clamps them against the brake rotor when... | |

| Brake Pads | Auto brake pads manualare essential components in automotive braking systems. They create friction against the brake rotors when the brake pedal is... |

Same products

| Engine Timing Tensioner Drive Pulley | Seller: Xuzhou Golden Motor Import & Export Co., Ltd | Ford Escort / Ecosport / Focus Engine Timing Tensioner Drive Pulley (OE: GN1G6K245BD) Keep your ... | |

| Bently Nevada AC Power Supply PN 127610-01 of 3500/15 | Seller: CW Green Tech | Bently Nevada AC Power Supply PN 127610-01 of 3500/15 3500/15 127610-01 | Bently Nevada | 3500/... | |

| SMC Auto Parts | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | SMC Auto Parts Description Auto parts made from sheet molding compound (SMC) are typically 25-... | |

| Clutch Cylinder | Seller: Qllino Automotive Industrial Limited | The car clutch cylinder, a crucial component in manual transmission vehicles, facilitates clutch ... | |

| Brake Pads | Seller: Qllino Automotive Industrial Limited | Auto brake pads manualare essential components in automotive braking systems. They create frictio... |