Inconel X750

We are leading manufacturer and stockist of Inconel X750 in China.Inconel X750 Technical Data Sheet Inconel X750 Chemical Composition LimitsWeight %Ni +(Co)CrFeTiAlNb + (Ta)MnSiSCuCCoX-750

UNS N0775070 min14-175-92.25-2.750.40-1.00.70-1.21 max0.50 max0.01 max0.50 max0.08 max1 maxUNS N07752 is available in billets for forging. UNS N0772 has limits of 0.05% on both Carbon and CobaltInconel X750 is a nickel-chromium alloy which has been made precipitation-hardenable by the additions of aluminum and titanium. Inconel X750 has good resistance to corrosion and oxidation along with high tensile and creep rupture properties at temperature up to 1300ºF (700ºC). Due to X-750's excellent relaxation resistance it is useful for applications as high-temperature springs and bolts,Website:, X-750 is also used in gas turbines, rocket engines, nuclear reactors, pressure vessels, tooling and aircraft structures.Inconel X750 Mechanical PropertiesMaterialSizeUltimate

Tensile Strength ksiYield Strength (0.2% Offset) KsiElongation in 4D(%)% Reduction of AreaAlloy X-750 BarUnder 4.0"165.01052025Alloy X-750 Bar4.0 " and over1601001517Properties as described in AMS 5667 which requires that material following 1625°F/24 hrs, AC-Equalising + precipitation treatment have the following minimum room temperature properties. Hardness will lie in the range of 302-363 BHNRod, Bars and Forgings are available with the following heat treatments

AMS 5667 - 1625°F/24hr, AC + 1300°F/20 hr, AC (Equalising plus precipitation treatment). AMS 5667 Rod, Bars and Forgings have high strength and notch rupture ductility up to 1100°FAMS 5668 - 2100°F anneal + 1550°F/24 hr, AC, +1300°F/20hr, AC (triple heat treatment). AMS 5668 has maximum creep, relaxation and rupture strength above about 1100°F. AMS 5670 - 1800°F anneal + 1350°F/8hr, FC to 1150°F. Hold at 1150°F for total precipitation-treating time 18 hr, AC (solution treatment plus furnace cool precipitation treatment). Due to the heat treatments AMS 5670, AMS 5671 and AMS 5747 have increased tensile properties and reduced heat treatment time service up to about 1100°F.With a heat treatment of 1800°F anneal + 1400°F/1hr, FC to 1150°F, hold at 1150°F for total precipitation-treating time of 6 hr, AC (solution treatment plus short furnace-cool precipitation treatment). This treatment of short furnace cool aging achieves only slightly lower properties than does AMS 5670 and AMS 5671. Rods and Bars X-750 is available from 1/2" diameter to 6" diameter in 1/4" increments. From 6" diameter to 10" diameter it is available in 1/2" increments.

MaterialSizeTensile Strength ksiYield Strength (0.2% Offset) KsiElongation in 2"(%)% Hardness RcAlloy X-750 Sheet

Annealed Condition0.010 to 0.024", incl140 max-30 min-Alloy X-750 Sheet

Annealed Conditionover 0.024 - 0.125" incl130 max60 max40 min-Alloy X-750 Sheet

Annealed Conditionover 0.125 - 0.250 incl130 max65 max40 min-Alloy X-750 Sheet

After Precipitation Treating (1300°F/20hr, A.C)0.010 to 0.025 incl165 min105 min20 min32 minAlloy X-750 Plate

After Precipitation Treating (1300°F/20hr, A.C)0.187 to 4.000, excl155 min100 min20 min30 minSheet, Strip and Plate are available with the following heat treatments

AMS 5542 - 1300°F/20hr, AC (Constant-temperature precipitation treatment). AMS 5542 has high strength up to 1300°F

AMS 5598 - 1350°F/8hr, FC to 1150°F, hold at 1150°F for total precipitation-treating time of 18hr, AC (furnace-cool precipitation treatment. AMS 5598 has high strength up to 1300°F (Increased tensile properties to about 1100°F).With heat treatment 1400°F/1hr, FC to 1150°F hold at 1150°F for total time of 6hr, AC (short furnace-cool precipitation treatment).

MaterialTensile Strength ksiYield Strength ksiElongation in 4D(%)% Reduction of AreaHardnessInconel X750

N07752 Type HRCAlloy X-750 Heat Treatment - Solution Treat 1.2 hrs @ 1975°F and Air Cool

Precipitation Heat Treat 20 hrs @ 1320°F and Air CoolUNS N07752 is available in billet for forging. UNS N07752 has limits on the Carbon and Cobalt levels (each has a maximum of 0.05%). Inconel X750 SpecificationsRodASTM B 637, ASME SB 637, ISO 9723, ISO9724, ISO9725, AMS 5667, AMS 5668, AMS 5669, AMS 5670, AMS 5671, AMS 5747, EN10269BarASTM B 637, ASME SB 637, ISO 9723, ISO9724, ISO9725, AMS 5667, AMS 5668, AMS 5669, AMS 5670, AMS 5671, AMS 5747, EN10269Forging StockASTM B 637, ASME SB 637, ISO 9723, ISO9724, ISO9725, AMS 5667, AMS 5668, AMS 5669, AMS 5670, AMS 5671, AMS 5747, EN10269PlateISO 6208, AMS 5542 and AMS 5598SheetISO 6208, AMS 5542 and AMS 5598StripISO 6208, AMS 5542 and AMS 5598WireBS HR 505, AMS 5698, AMS 5699OtherUNS N07750, W.Nr 2.4669, Inconel X750 (tradename), UNS N07752The Inconel X750 items which we can manufacture and supply are the followings.

Inconel X750 Rod

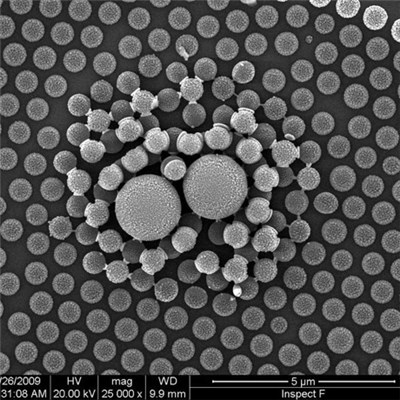

3D printing spherical powder Inconel X750

Inconel X750 Rings

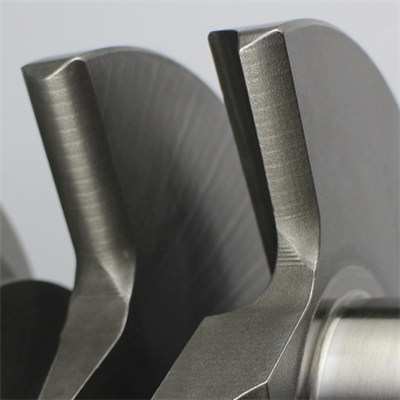

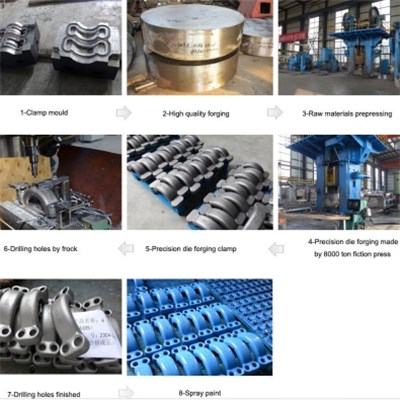

Inconel X750 Forgings

Inconel X750 pipe

Inconel X750 tube

Inconel X750 bars

Inconel X750 plates

Inconel X750 sheets

Inconel X750 Strip

Inconel X750 wire

Inconel X750 fitting Union

Inconel X750 Pipe Elbows

Inconel X750 PIPE Tee

Inconel X750 ADAPTERS

Inconel X750 pipe bend

Inconel X750 reducers

Inconel X750 fitting caps

Inconel X750 pipe outlets

Inconel X750 Stub Ends

Inconel X750 Couplings

Inconel X750 pipe Nipples

Inconel X750 BUSHINGS

Inconel X750 pipes sockets

Inconel X750 Pipe Gasket

Inconel X750 pipe joints

Inconel X750 pipe Cross

Inconel X750 Pipe Wyes

Inconel X750 seal ring

Inconel X750 Flange

Inconel X750 bolts

Inconel X750 nutsONE OF THE KIND, MILLIONS OF CHOICES SUPERIOR QUALITY PROMPT DELIVERY FAVORABLE FEEDBACK ALL AVAILABLE IN PESCO SELECT PESCO, YOU WILL BE RIGHT For more info and price of Inconel X750, please send us inquiry and you will have quick reply soon.

Other supplier products

|

|

BS S98 |

We are leading manufacturer and stockist of BS S98 in China.Aircraft Steel BS S98 / 2S98D (826M40)BS S98 Technical Data SheetBS S98 Chemical Compos... |

|

|

High Pressure Self-energized Flange P-loc |

We are leading manufacturer and stockist of High Pressure Self-energized Flange P-LOC in China.High Pressure Self-energized Flange P-LOC despriptio... |

|

|

Magnesium Alloy HM21A |

We are leading manufacturer and stockist of Magnesium Alloy HM21A in China.Magnesium Alloy HM21A Magnesium Alloy HM21A Technical Data SheetChemical... |

|

|

BS3059-1 HFS 360 Boiler Tubes |

We are leading manufacturer and stockist of BS3059-1 HFS 360 boiler tubes in China.BS3059-1 HFS 360 boiler tubes are made from heat resisting carbo... |

|

|

STAINLESS 316 |

We are leading manufacturer and stockist of STAINLESS 316 in China.Technical Data Sheet of STAINLESS 316Chemical Composition OF STAINLESS 316Weight... |

All supplier products

Same products