Bio-polishing Enzyme QM-111

[Main composition]Cellulosic enzyme compound

[General properties]Appearance: Brown liquidpH: 4.5-5.0

[Productfeatures]

Effectively remove exposed the pale and yarn end, improve the fabric hand feels and shine.Bio polish enzymecan reduce pilling and improve hydrophilicity.Suitable for removing surface fluff of cellulose fibre.It can improve the smooth surface of the fabric and give a good hand feeling after processing.

[Application]Suitable to cotton , mucilage, flax and ramie fabric.

- PH: 4.0-5.5Bio-polishing Enzymes: 0.5-2% (o w f)15-40 minutesTemperature: 50-55℃Bath radio: 1:5-15

- 1) Please add water at 1:5-15 bath radio, washing agent 0.25-0.5% and heat to 85℃at 10 minutes. final with drain and washing2) Adjust PH to 10-10.5 for 10 minutes, and then drain.

[Packaging and25 kg/polyethylene drum, keep it cool and dry, 6 months in sealed container under 25℃can keep the activity.。

[Notes]The data contained in this literature are based on our current knowledge and experience. It is imperative that it be tested to determine, to your satisfaction, whether it is suitable for your intended use and application. We shall not take any responsibility in any situation for improper use.

[Sample supply]If you need samples for testing, please feel free to contact us, we will recommend suitable products according to your requirement.

[Shipment]We can support LCL shipment and FCL shipment, for LCL shipment, we will pack the goods with wool pallet to save the products during transportation.

[Quotation]According to your order quantity, we can supply FOB, CIF, EXW price.

[Order MOQ]Normally,HT Fineorder MOQ is 3 tons per model and we can offer lowest price with more quantity.

HT Fine Chemical Co., Ltd (be called for short "HT"), founded in year 2005, is a large scale textile chemical companyin Qingyuan City, Guangdong Province,China.

Send product request

Other supplier products

| Antisatic Agent KD | This product is suitable for polyester, polyamide, such as polyvinyl chloride staple fibre spun synthetic fiber spinning static elimination, with e... | |

| Acid Donor 2143 | Acid Donor2143 Apply to dyeing of mordant dyes, metal complex dye and acid dyes of mercerized wool and chinlon and make dye bath pH slipping to ... | |

| Auxiliaries for Cotton | Cotton dyeing is operated in a certain temperature, time, PH value and the required dyeing agent for cotton. The common dye fixing agent for cotton... | |

| Retarding Agent for Acrylic RCT | Cationic surfactant for acrylic fiber has strong affinity, can before cationic dyes dyeing acrylic fiber, and then be cationic dye replacement sl... | |

| Anti-slipping Agent FH | To improve the yarn anti slip agentand all kinds of fiber woven fabric softness product, especially the lining of regenerated fiber or synthetic fi... |

Same products

| Peptide Technology Cooperation & Transfer | Seller: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

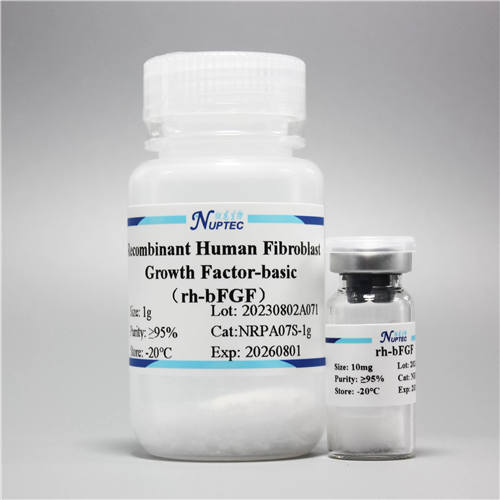

| Recombinant Human Fibroblast Growth Factor-basic | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

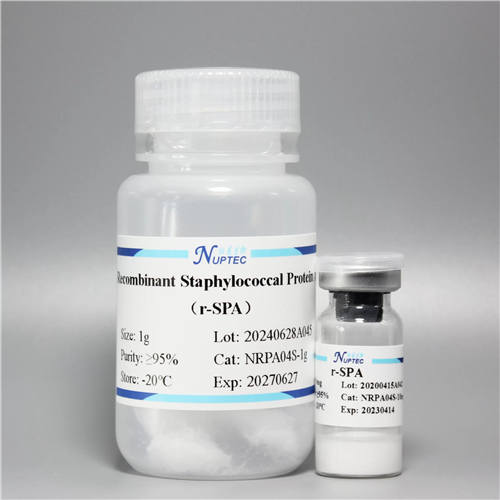

| Recombinant Staphylococcal Protein A | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |