Abrasive Material Used in Shipbuilding Industry

Whether in the past or in the future, we should know that abrasive materials play an important role in industrial development. The land and the ocean together constitute the space for human activities, and the ocean occupies most of the space. The development of the shipbuilding industry will be the top priority for a long time in the future. It can also be seen from this that the shipbuilding industry is also a big industry. The main applications of abrasive material in the shipbuilding industry are mainly concentrated in sandblasting, painting, coatings and so on.

Function of Abrasive Material in Shipbuilding Industry

Powdered natural abrasive materialhas been used in ship sandblasting for quite some time, but now some shipyards have begun to study alternatives to sandblasting. For example, the steel shot peening technology is used to remove the oxide scale and rust on the surface of the steel plate, and then the primer is sprayed in the spraying workshop, which can protect the steel plate from rusting during the shipbuilding process. The increase in shipbuilding has also increased the number and size of segments. At present, the sectional brick spraying rooms of various factories can no longer meet the requirements of secondary rust removal. Therefore, more and more manufacturers have begun to adopt the outdoor copper slag spraying process.

If you want to know more applications of tabular alumina for ladle casting, please visit our website.

More details of abrasive material list, please contact us.

Send product request

Other supplier products

| Green Silicon Carbide | Green silicon carbideis produced as the same type as the black silicon carbide, except the different raw materials. Its crystallization has higher ... | |

| White Fused Alumina for Refractory | As a kind of refractory materials, white fused alumina gritis generally used for aggregate and fine powder, because it has the characteristics of h... | |

| White Fused Alumina for Refractory | As a kind of refractory materials, white fused alumina is generally used for aggregate and fine powder, because it has the characteristics of high ... | |

| Brown Fused Alumina | What is brown fused alumina Brown fused alumina is a versatile product available in various forms. It includes brown fused alumina for abrasive, b... | |

| Brown Fused Alumina For Abrasive | Brown Fused Alumina For Abrasive Cooled and smelted under an electric arc at a high temperature above 2000 degrees, brown fused alumina for abrasi... |

Same products

| Peptide Technology Cooperation & Transfer | Seller: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

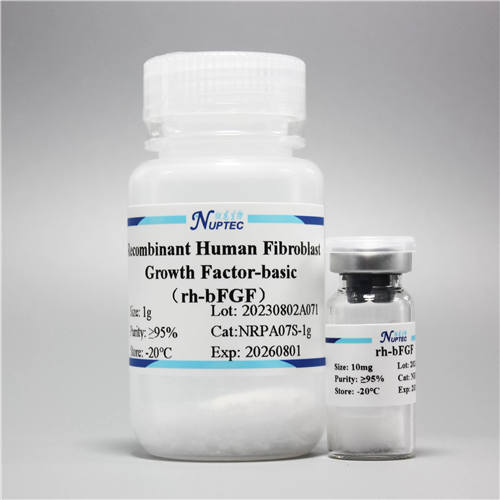

| Recombinant Human Fibroblast Growth Factor-basic | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

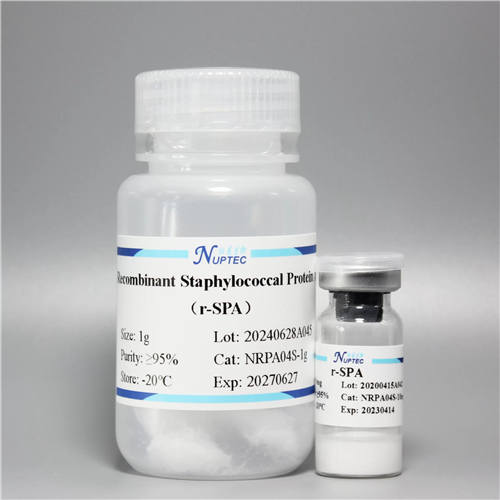

| Recombinant Staphylococcal Protein A | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | Seller: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |