HAI Q Software Platform

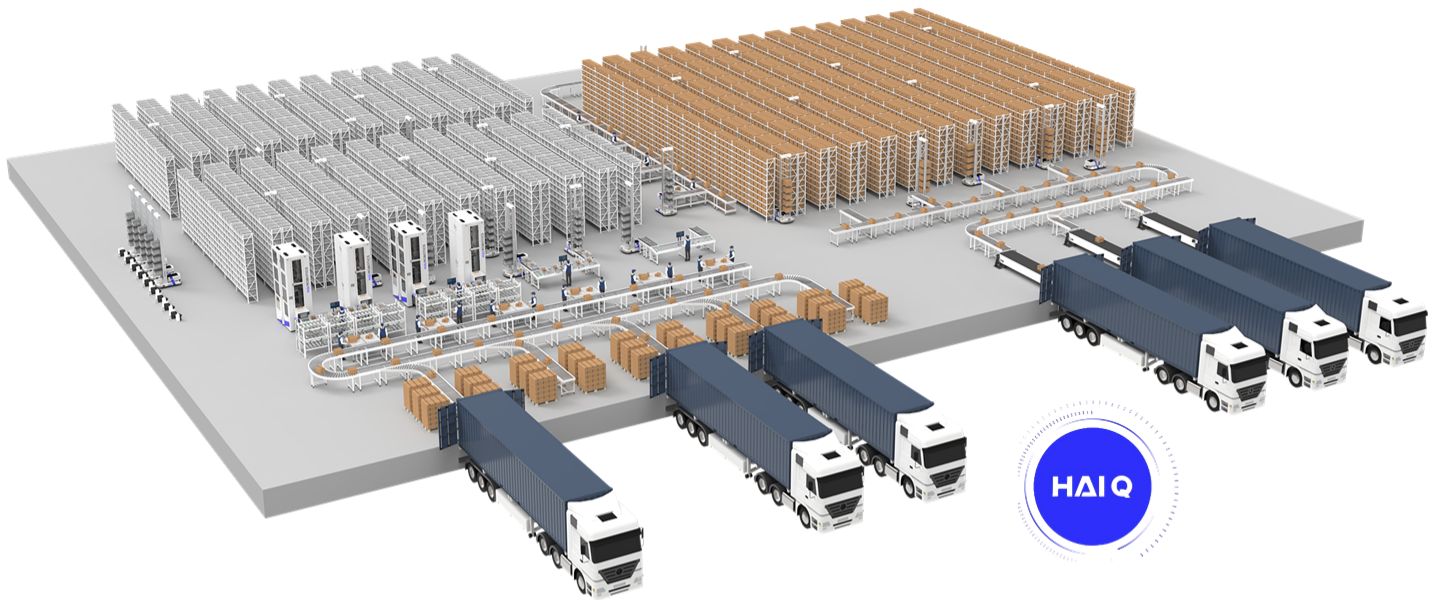

HaiQ Warehouse Automation SoftwarePlatform

HaiQ is an intelligent software platform that leverages AI algorithms to streamline order fulfillment and inventory management. It serves as the central command for inbound, outbound and inventory management, seamlessly integrating with other devices.

Thorough R&D

Results in rugged software with seamless integrations

Flexible Configuration

Meet the specific demands of the warehouse process

Flexible Scheduling

Support quick integration of multi-type equipment and coordination

Service Oriented Architecture

Modular in-house developed software environment easily adapts to any changes in your business

Intelligent Resource Orchestration

Optimize capacity and space utilization

Continuous Algorithmic Optimization

Achieve operational optimization with AI

Warehouse Execution System (WES)

Hai Robotics Warehouse Execution System (WES) is a smart system that seamlessly interfaces with upstream systems such as ERP, WMS, MES and supports operations such as outbound, inbound, inventory check, stock consolidation and material handling. The system features flexible workstation configuration and operation strategies, such as order grouping, order splitting, wave rule and heat strategy.

* Convenient Upstream System Access

We have experience in implementing projects with well-known ERP and WMS vendors, allowing for flexible field configuration to meet various docking requirements.

* Efficient Configuration and Algorithms

Configure workstation operation rules, support business strategies such as grouping and splitting orders, and have intelligent and efficient algorithms.

* Standard Deployment Plan

It has high availability with automatic switching in case of failure, as well as load balancing and data disaster prevention features.

* Stable and Secure Platform

Capable of processing up to 10,000 external requests per second. The data communication between robots uses encrypted components.

Equipment Schedule System (ESS)

Hai Robotics Equipment Scheduling System (ESS) integrates robots, equipment, and physical environment information into a unified management system, including task management, resource management, and map monitoring and other functions. It receives instructions from upstream systems to control various types of warehouse robots to perform material handling tasks.

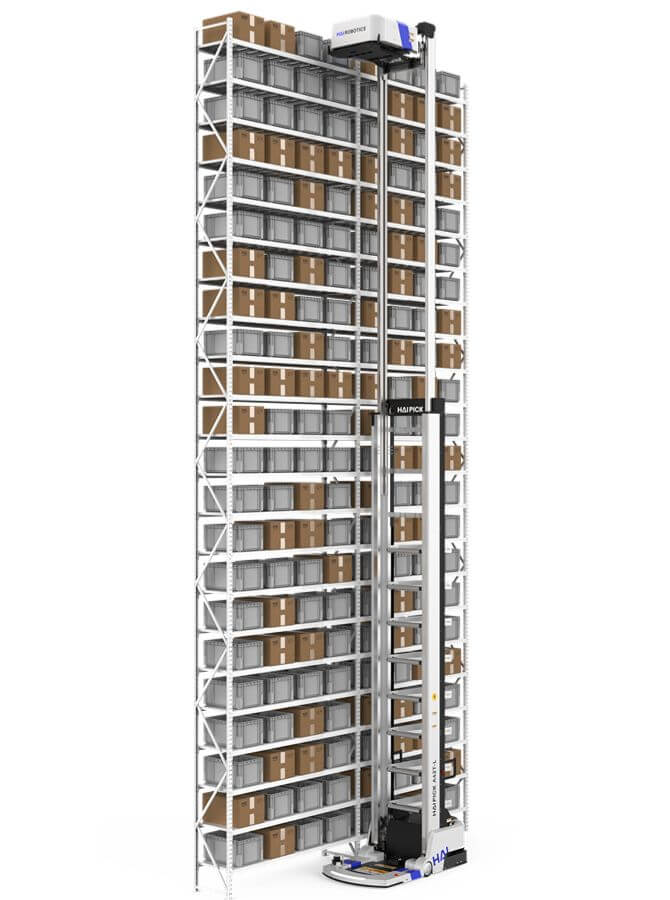

* Rich Equipment Integration

Integrated with HaiPick, HaiPort, HaiFlex, conveyors, pick to light system, emergency stop switches, guard doors, etc.

* Multi-type Robot Mixed Field Operation

Mixed scheduling of multiple types of AGVs, such as scheduling HaiPick, HaiFlex.

* Efficient Task Linking

Multiple devices work in parallel to complete related tasks, reducing mutual waiting.

* Large-scale Robots Scheduling

Capable of scheduling over 1000 robots.

Data Platform

The Data platform collects and integrates data from various systems, including WES, ESS, and Robots. It centralizes the processing of data related to warehouses, robots, equipment, personnel, and commodities.

Using intuitive and easy-to-understand visualization interface, the value of data analysis can be demonstrated, such as warehouse traffic, work efficiency, providing management and decision-making basis for business managers.

Simulation Platform

The Simulation Platform creates a virtual warehouse by inputting map files, order files, inventory files, and demand configurations. By incorporating the actual customer scenario's demand parameters, the platform conducts a 1:1 simulation.

Using the simulation results of robot operations, the project plan is swiftly verified, and strategies and on-site configurations are promptly adjusted to promote the best solution. This helps customers achieve maximum project benefits.

AI Algorithm Platform

As the intelligent brain of the HAI Q system, the AI Algorithm Platform is responsible for the analysis, computation and decision-making of various systematic scenarios. Intelligent analysis, high-efficiency computing and smart decision-making remarkably improve the operating efficiency of the system to the greatest extent.

* Order Allocation Algorithm

Select orders from the order pool and assign them to workstations to maximize order timeliness, picking efficiency, and workload balance.

* Task Allocation Algorithm

Assign tasks to robots to ensure optimal transport efficiency and timely completion of transport tasks.

* Path Planning Algorithm

Minimize robot travel distance, achieve robot avoidance, queueing, and other actions, and reduce workstation downtime.

* Charging Algorithm

Provide stable and sufficient robot transport resources to ensure efficient completion of warehouse operations.

If you want to know more applications of our intelligent warehouse management systemand robot management system, please visit our website.

Hai Robotics is the pioneer and leader in warehouse automation and robotics systems. The company is committed to providing efficient, intelligent, and flexible automation solutions through advanced robotics and AI algorithms creating value to every warehouse and factory.

Send product request

Other supplier products

| Apparel Warehouse: Bosideng Moves from Manual to Automation with ACR System | World's No. 1 down garment producer Bosideng has joined forces with Hai Robotics to transform its apparel warehouse from manual to automated. The a... | |

| Healthcare | Healthcare Supply Chain Automation Due to aging populations and increased disease rates, medical spending as a percentage of GDP is rising while h... | |

| HaiPick A42 | Multi-Layer ACR HaiPick A42 The A42-series offers picking and storage of cases up to a height of 5.2m (17.1 feet). The series consists of four mode... | |

| ACR Systems | Autonomous Case-handling Robot (ACR) systems are highly efficient Goods-to-Person solutions designed for totes & cartons transportation and pro... | |

| Telescopic Lift ACR | HAIPICK A42T The HAIPICK A42T Telescopic ACR is the world's first ACR that can pick and store plastic totes and carton boxes at a dizzying height ... |

Same products

| Raspberry Pi CM5 Embedded Computer No.BL460 | Seller: BLIIOT | Industrial AI Embedded Computer BL460 based on the Raspberry Pi CM5 module and compatible with th... | |

| 4*A76 RK3588 ARM Based AIoT Edge Computer No.BL450 | Seller: BLIIOT | BL450 is a fanless AI computer and industrial PC built on the Rockchip RK3588J/RK3588 with quad-c... | |

| 4*A72 RK3576 ARM Based Mini Industrial Computer No.BL440 | Seller: BLIIOT | BL440 is an ARM based industrial PC from the ARMxy series, built on Rockchip RK3576J/RK3576 with ... | |

| 4*A55 RK3568 Fanless ARM Industrial PC No.BL410 | Seller: BLIIOT | BL410 is a fanless ARM industrial PC powered by the RK3568J/RK3568B2 with quad-core Cortex-A55 up... | |

| 4*A53 RK3562J Linux ARM Edge Computer No.BL370 | Seller: BLIIOT | BL370 Linux ARM computer built on Rockchip RK3562/RK3562J with quad-core Cortex-A53 and Cortex-M0... |