CNC MACHINING

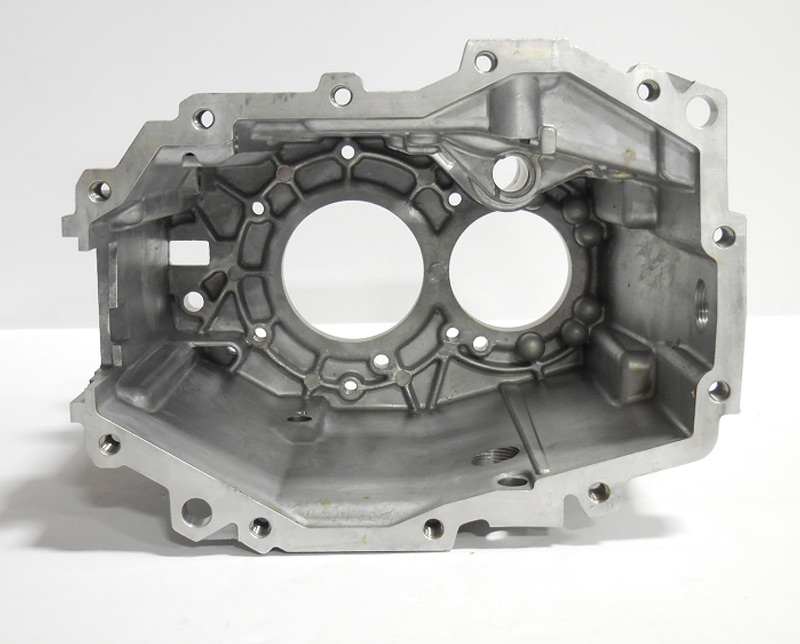

CNC Machining is directly changing the size, shape, mutual position, surface roughness or properties of raw materials or semi-finished products to make them into finished products.

Including: casting, welding, electroplating, heat treatment, machining and assembly processes.

The process of removing the surface material of the part by metal cutting, the process of obtaining the finished product is called a machining process.

CNC Precision Machining

Generally speaking, a machining process normally refers to the process of removing the surface material of the part and obtaining the finished product. However, in order to obtain a well-refined product, people were used to take many steps and the whole process could take a relatively long time. Whereas, as the CNC precision machining eventually made its entrance into the industry, this situation has been greatly improved.

Capable of performing a variety of processes like casting, welding, electroplating, heat treatment, machining, and assembly, precision cnc machining chinacan directly change the size, shape, position, surface roughness and other properties of raw or semi-finished materials and transfer them all into well-finished and refined final products. Therefore, having solved the problems of complex, precise, small batch, and multi-variety parts processing, cnc precision machining China, or the so-called CNC precision milling, has now gradually become an important part in metal processing. And as a professional china aluminum machining factory, EMP Techcan provide you with the best aluminum CNC service in China.

The Basic Working Process Route for CNC Precision Machining

Processing the reference surface

when the raw material is placed for the process of machining and manufacturing services, the surface of the material should be processed first so as to provide a fine reference for the processing of the subsequent process.

Dividing the processing stage

The processing of a high-quality surface with precision CNC milling can normally be divided into 3 processing stages: roughing, semi-finishing and finishing. With the setting of these processing stages, the CNC turning & milling can then be conducted precisely and clearly.

Machining the plane-finished holes

As for the production of precise and small aluminum parts, such as brackets and connecting rods, the plane-finished holes has to be firstly machined by the CNC machine. By doing so, these firstly machined holes can then perform effectively as accurate references for the positioning of the following steps.

The finishing of the main surface (such as grinding, fine grinding, rolling, etc.) should be carried out in the final stage of the process. And it should be noted that during this stage, the processed parts should be treated carefully as any slight collision can damage the surface.

Five Major Technical Support for CNC Precision Machining

Advanced manufacturing technology

High-precision, high-efficiency automated processing equipment

Advanced logistics technology

Advanced control technology

Modern management technology

Five Major Technical Support for CNC Precision Machining

The Advantages of CNC Precision Machining

As for CNC machines, they have strong adaptability in terms of processing objects. They can provide suitable processing methods for various mold manufacturing.

CNC milling service also has the characteristics of high processing precision and stable processing quality.

Since precision CNC machining is controlled by computers, multi-coordinate linkage can be easily carried out by CNC machines, and parts with complex shapes can also be processed.

Aluminum CNC programming services also possess the quality of high flexibility. When the design of the custom cnc aluminum chinaparts are changed, people will only need to change the NC program in the CNC machine and the whole machining process will be changed accordingly.

Since the machine tool is highly automated, labor intensity can then be greatly reduced.

Conducive to the modernization of production management, CNC machine tools use digital information and standard codes to process, transmit information, and use computer control methods to replace the foundation for the integration of computer-aided design, manufacturing and management.

The Possible Application of CNC Precision Machining

The production of small batch parts and custom CNC aluminum

The production of aluminium parts that need to be modified multiple times

The production of working parts with high machining accuracy requirements

The production of expensive parts, which can cost huge economic losses once they are scrapped

There are many aluminium casting suppliers, but we are one of the best choices for you.

Send product request

Other supplier products

| ALUMINUM CASTING RADIATOR | The radiator is a general term for a series of devices used to conduct and release heat. It is widely used in power electronics, communications, va... | |

| DIE CASTING PART | EMP Techis a global, full-service aluminum die casting manufacturer china. With more than 20 years' experience in research & development, manuf... | |

| CNC MACHINING | CNCprecision machining chinais directly changing the size, shape, mutual position, surface roughness or properties of raw materials or semi-finishe... | |

| DIE CASTING TOOLING/MOLD DESIGN | TOOLING DESIGN OVERVIEW New technology is breaking through constantly, driven by innovative thinking. The mold design team carries out new product ... | |

| WATER PUMP HOUSING | EMP Techis one of theglobal, full-service aluminium die casting manufacturers in china. With more than 20 years' experience in research & devel... |

Same products

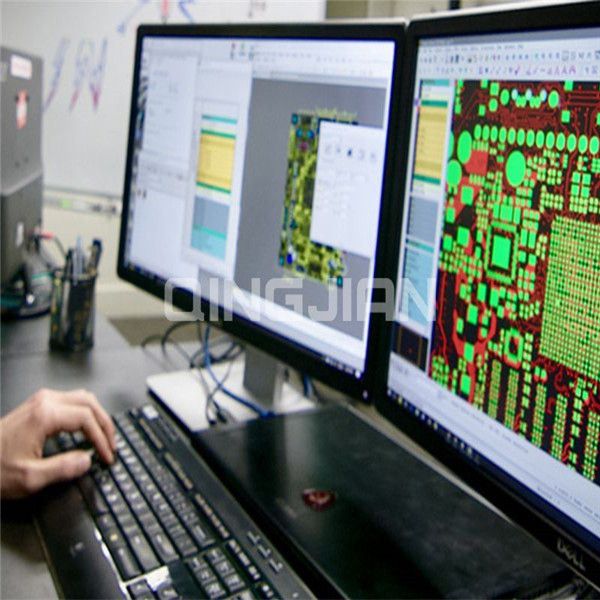

| PCB Assembly Service | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | Seller: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | Seller: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | Seller: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |