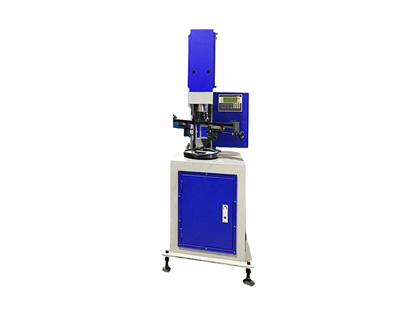

ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE

ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE

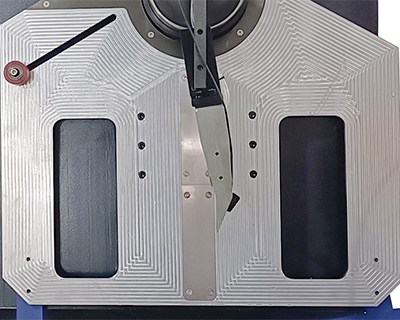

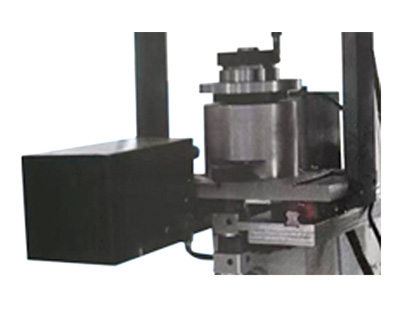

The equipment is designed for automatic crimpingand forming after welding of stainless steel rings of enamel pots. It is connected with our automatic laser welding equipment through a manipulator, and then rotated and crimped at high speed. The mechanized action adopts servo digital control, which greatly reduces the product replacement time. The product must be used with our fully automatic laser welding toolto form a fully automatic production line.

THE PARAMETER OF ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE

|

Input voltage |

Enter the frequency |

Product diameter |

Product thickness |

Product width |

Dimensions |

|

3*380V |

50HZ |

120~400mm |

<0.2mm |

8~18mm |

700*700*1700mm |

The Application Of Enamel Pot Stainless Steel Belt Crimping Machine

The equipment is a special equipment for the hemming process after the stainless steel welding of the enamel pot. The robotic arm grabs the workpiece, reducing labor costs. The mechanical action adopts servo digital control, which greatly shortens the product replacement time. The equipment is beautiful in appearance design, simple in operation, and easy to learn and understand.

The Advantages Of Enamel Pot Stainless Steel Belt Crimping Machine

The equipment is designed to occupy a small area, and the mechanical arm and the laser welding machine are combined for production, which changes the previous manual hemming. The equipment adopts information exchange control, which is perfectly unified with the previous process. The way of crimping is upside down, no need to add any lubricant.

Other Notes Of Enamel Pot Stainless Steel Belt Crimping Machine

Enamel pot stainless steel belt crimping machine Main Characteristics

1

Reducing labor can save costs and reduce scrap rate.

2

Beautiful appearance design, simple operation, easy to learn and understand.

3

The way of crimping is upside down, no need to add any lubricant.

4

The mechanical action adopts servo digital control to shorten the adjustment time.

5

Adopt information exchange control to achieve unified control with the previous process.

6

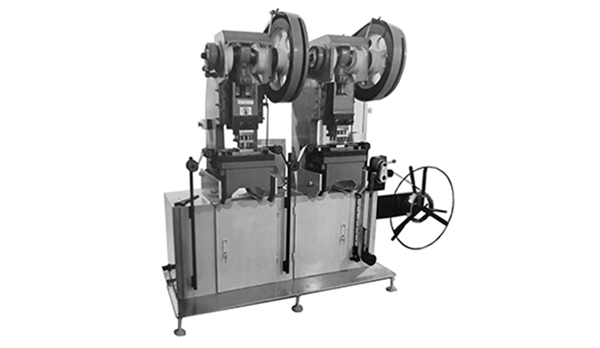

It can be used together with the laser welding equipment produced by our company to realize a fully automatic production line.

Send product request

Other supplier products

| BRAKE PAD SPOT WELDER | The automobile brake pad steel back spot laser welding machineadopts the intermediate frequency controller, which has high control precision, stabl... | |

| PAPER DRUM STAINLESS STEEL BELT LASER WELDER | PAPER DRUM STAINLESS STEEL BELT LASER WELDER The equipment is mainly aimed at the stainless steel of the paper drum, which is made of galvanized m... | |

| PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE | PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE This equipment is designed for crimping and forming after welding of paper drum stainless steel... | |

| AUTOMOBILE BRAKE DISC MILLING MACHINE | AUTOMOBILE BRAKE DISC MILLING MACHINE The equipment is a CNC milling machine developed and produced for the milling processing of the forklift bra... | |

| STAINLESS STEEL PUNCHING MACHINE | The cnc metal punching machineis punching equipment independently developed and produced by Ningbo Xihe Automation Equipment Co., Ltd. The equipmen... |

Same products

| PCB Assembly Service | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | Seller: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | Seller: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | Seller: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | Seller: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |