ZK linear vibrating screen

ZK linear vibrating screen

Use:

ZK linear vibrating screen, linear movement, suitable for coal preparation, coal washing, dressing, power and other industries, the fine grained material, dry and wet sieving, can also be dehydration

Stripping and desliming.

The principle of work:

Linear vibrating screen are seat mounted. The utility model is characterized in that the utility model adopts a double shaft vibration exciter, the motor does not participate in the vibration, and the two motors are driven to rotate synchronously with the action, so that the screen body can make periodic reciprocating motion along a straight line direction, thereby achieving the purpose of screening.

Performance characteristics:

Structure introduction:

ZK series linear vibrating screen is mainly composed of screen box, exciter, supporting device and motor. The screen box is supported by a rubber spring on the support, and the two shafts of the exciter are respectively driven by two asynchronous motors.

Installation and commissioning

Before installation should be carefully checked, according to the inventory list of equipment and random accessories are complete, at the same time should check whether the damage caused by the shipment and the loss of random accessories, and promptly notify the manufacturer.

1) support installation: the installation support device of bearing and motor frame before the foundation leveling, then adjust and install the bearing and motor frame, and then the rubber spring is installed in the spring.

2) the installation of screen box: sieve box adopts integral hoisting, lifting to the wire rope at the specified location (beam) are not allowed in the direct lifting vibrator, so as to avoid deformation. The screen box is then hung above the supporting position and then slowly lowered to make it located on the spring.

3) motor installation: installation, the horizontal motor needs correction, axial center lines of the output shaft of the electric motor and the vibrator should be coincident or slightly below the exciter shaft center line, but not more than 5mm. After the motor is installed in a predetermined position, the connecting wire is connected with the motor and the electric network, and the rotation direction of the two motors is opposite.

4) check the connecting parts (such as vibration sieve plate, vibration etc.) fixed, lubrication of the transmission part of the motor wiring is correct, and the hand rotation driving part, to see whether normal movement.

5) check the exciter rotation is flexible, moving the coupling to the exciter eccentric block from the equilibrium position, and then suddenly let go, the eccentric block should be several times the swing, if the move or not to move, it should be carefully to find out the reasons and adjust.

6) if the vibration screen from the date of shipment to the shipment for more than half a year, or due to improper storage caused by rust and so on should be removed and cleaned the vibration exciter, before installation and use.

1) empty sieve test run time shall not be less than 8 hours. During this time, observe whether to start the sieve quickly and smoothly, whether the vibration and stable operation, there is no special noise.

2) screen operation, vibration sieve box should not produce yaw. As a result of yaw, the reason may be too large or spring height on both sides of the rotating shaft is not level, we should make the corresponding adjustment.

3) if there is an abnormal noise or a sharp increase in bearing temperature after driving, stop immediately, check whether the bearing is flexible and the lubrication is good or not.

4) after driving 2 ~ 4H stop check the connection parts are loose, if there is loose, to be fastened and then drive.

5) after the commissioning of the 8h, if there is no fault, the installation works can be checked and accepted.

Operation and maintenance operating points :

Technical parameter:

|

Model |

Sieve surface |

Feeding granularity (mm) |

Power(KW) |

Capacity (t/h) |

Weight (t) |

||

|

Area (m2) |

Mesh size (mm) |

Sieve mesh structure |

|||||

|

ZK1022 |

Weaving/Strip/ Stamping/ Rubber/ Polyurethane sieve mesh |

<250 |

3×2 |

||||

|

ZK1230 |

<250 |

4×2 |

|||||

|

ZK1237 |

<250 |

|

9-180 |

||||

|

ZK1437 |

<250 |

|

12-250 |

||||

|

ZK1445 |

<250 |

|

|||||

|

ZK1637 |

6 |

<250 |

|

12-240 |

|||

|

ZK1645 |

<250 |

11×2 |

95-280 |

||||

|

ZK1837 |

<250 |

11×2 |

90-270 |

5 |

|||

|

ZK1845 |

<250 |

11×2 |

|||||

|

ZK1852 |

<250 |

11×2 |

|||||

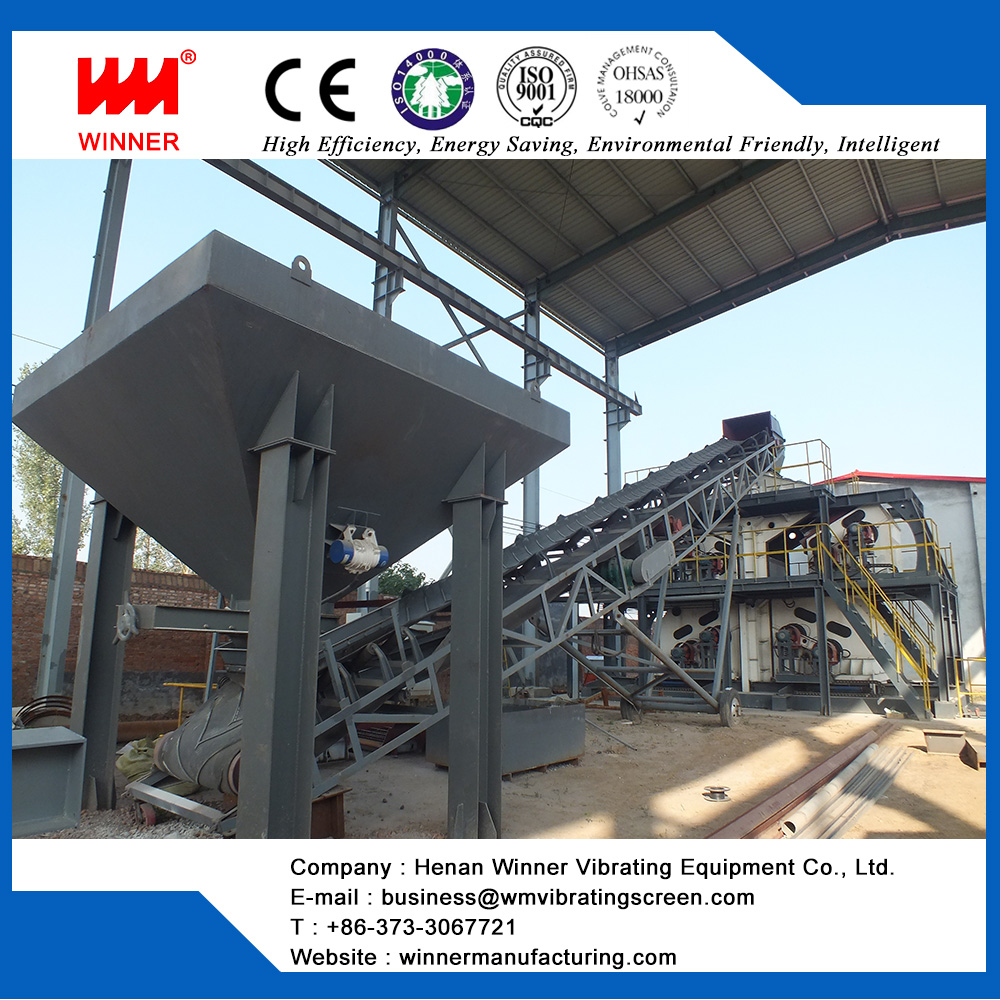

Application:

ZK linear vibrating screen trajectory is linear, for coal preparation, coal washing, mineral processing, power generation and other industries, On the medium and fine materials dry and wet screening, Can also be dewatering, Off medium, desliming operations.

Summary:

Linear vibrating screen are seat type installation, using a biaxial exciter, motor does not participate in vibration, by the two motor with the reverse self-synchronous rotation, so that the screen in a straight line for the cyclical reciprocating motion, so as to achieve the purpose of screening.

Send product request

Other supplier products

| Stock and stone crushing machine for waste recycling | Introduction Overview of Stock and stone crushing machine for waste recycling: Stock and stone crushing machine for waste recycling is the crusher... | |

| WYA series circular vibrating screen for mining | WYA series circular vibrating screen for mining Uses and characteristics of WYA series circular vibrating screen for mining: The circular traject... | |

| Double frequency probability combination sieve | Double frequency probability combination sieve Principle of double frequency probability combination sieve: Overview of: Features: Under th... | |

| Mining plane rotary vibrating sieve for food | Product overview of Mining plane rotary vibrating sieve for food: Mining plane rotary vibrating sieve for food is the most effective sieve screeni... | |

| High amplitude vibration screen, circular vibrating screen for mining | High amplitude vibration screen, circular vibrating screen for mining Applications of High amplitude vibration screen, circular vibrating screen f... |

Same products

| 4-Shaft Winder Cast Film Machine | Seller: Wenzhou Chaoshun Machinery Co., Ltd. | The 1500–2100mm PVC Cast Film Machine (4-Shaft Winder) is a robust solution built for indus... | |

| Standard Washer 12/15/20/25kg | Seller: Jiangsu Chuandao Intelligent Equipment Co., Ltd. | Kingstar Series washer extractors equipped with the world’s leading washing technology, Ita... | |

| Daily Necessities Molds | Seller: Zhuozhou Yihua Mould Factory | Daily Plastic Products are the most extensive category of plastic products. Most of the plastic p... | |

| Rebar Coupler Threading Machine | Seller: Xingtai Yushi Machinery Equipment Co., Ltd | Rebar Coupler Threading Machineis an essential tool for processing reinforced bars, commonly used... | |

| VH HIGH-SPEED GANTRY PROCESSING | Seller: Ling Yueyang International Trade (Shenzhen) Co., Ltd | ●Powerful cutting capability combined with high precision and performance makes insert and armori... |